Linus Lil’ Roadster 20" User manual

Lil’ Roadster 16”/20” | Lil’ Dutchi 16”/20” | Linus Balance

ASSEMBLY GUIDE

KID’S BIKES

1-SPEED

COASTER

Illustrations are based off of Roadster Classic but instructions apply to all of these models:

Please review Assembly Guide in its entirety before beginning bicycle assembly. If you do not feel fully

capable of assembly or do not have the proper tools please contact your local bicycle shop to assemble.

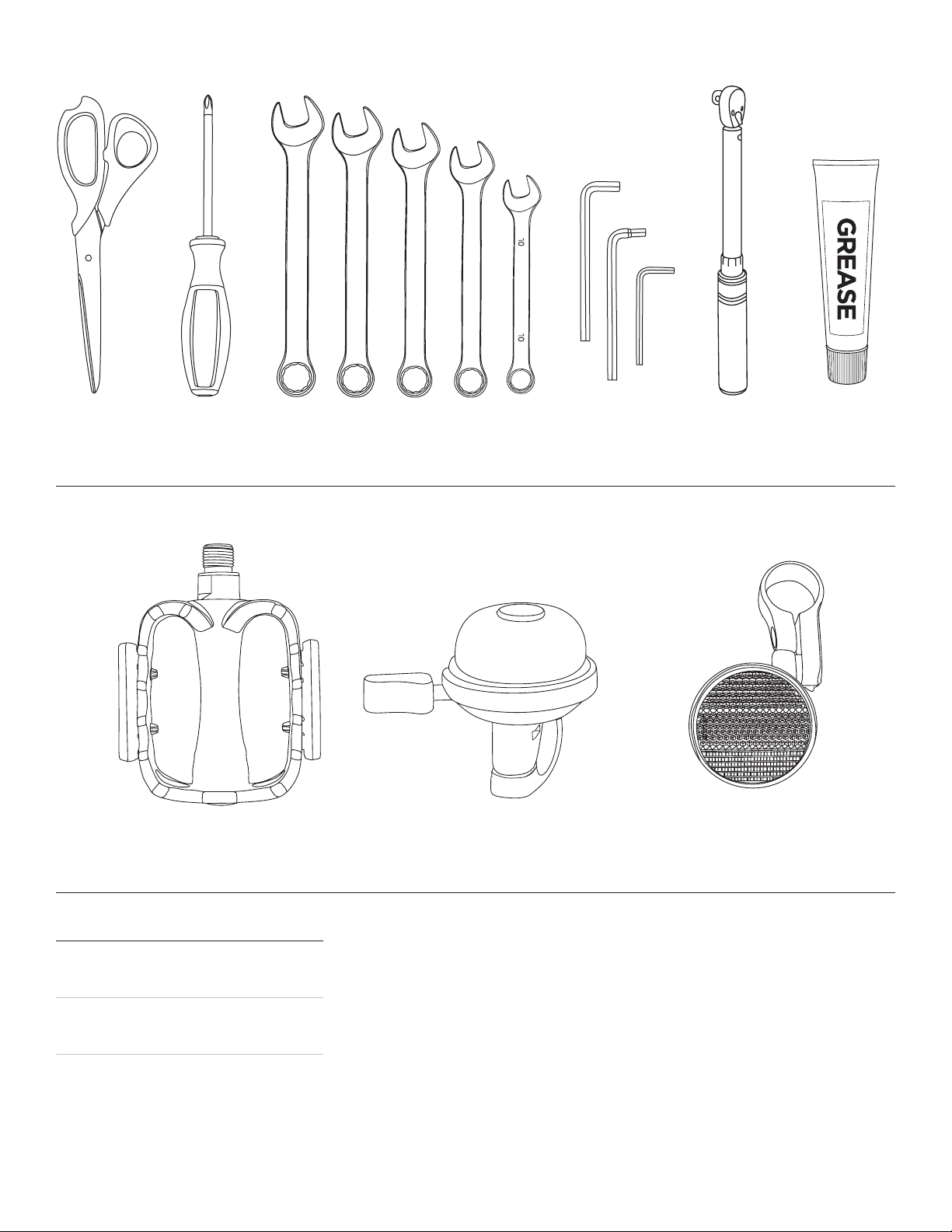

ALLEN WRENCH

6MM, 5MM, 4MM

2

LUBRICATING

GREASE*

WRENCH

15MM, 14MM, 13MM, 12MM, 10MM

14 14

13 13

12 12

15 15

Required Tools (not included)

SCISSORS PHILIPS HEAD

SCREWDRIVER

Parts (included)

Unpacking

Open top of the bicycle box. Remove

bicycle, saddle and parts box.

We recommend using the flat box as a

work surface for bicycle assembly.

Remove protective packaging carefully.

Do not bend spokes when removing the

front wheel.

PEDALS

x2

BELL

x1

REFLECTORS

x2

* Available at auto parts, hardware, or bicycle stores.

** Failure to tighten bolts to the required torque specications can lead to

component failure ultimately leading to serious injury or death.

TORQUE

WRENCH**

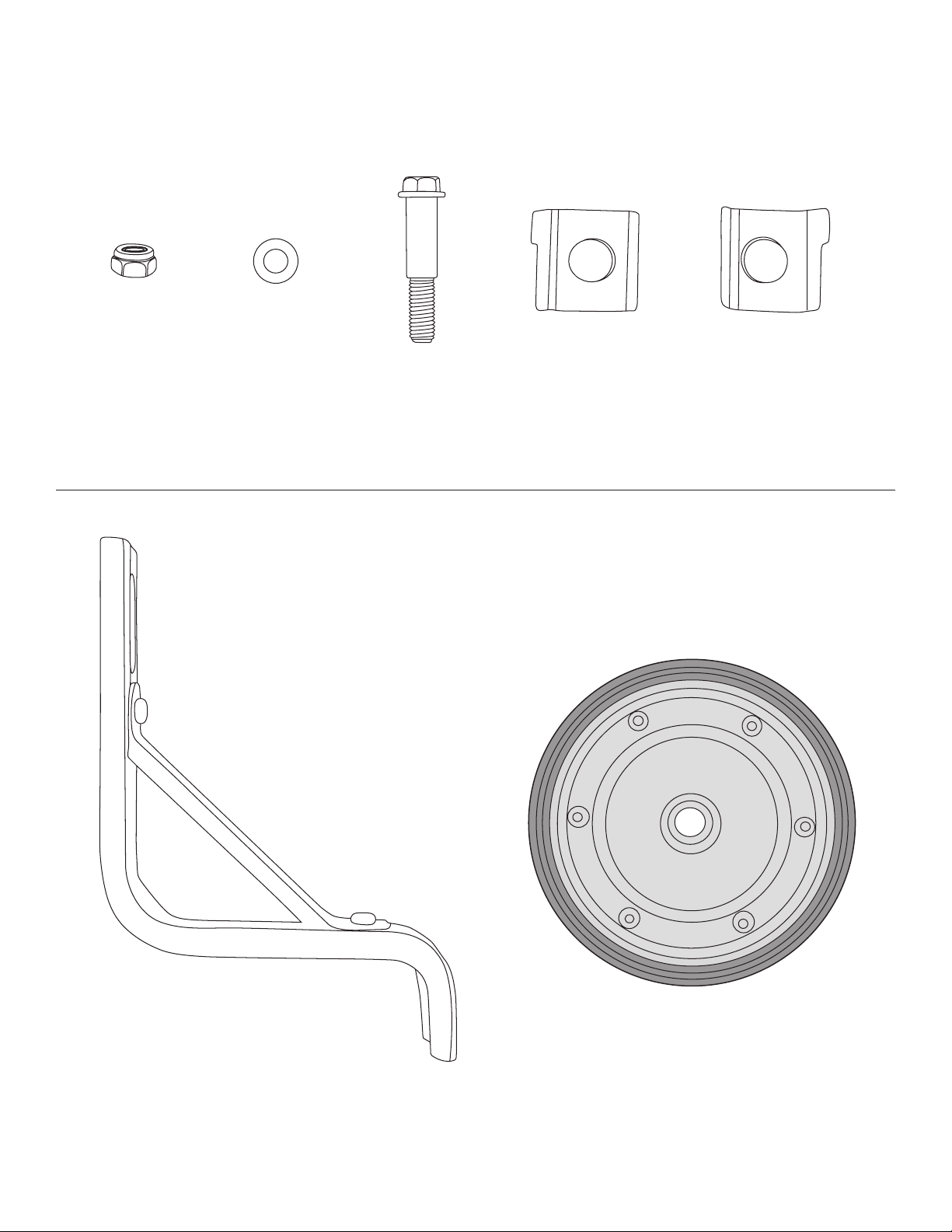

Training Wheel Parts (only included with 16” bike models)

LOCKING NUTS

x2

TRAINING WHEEL BRACKETS

x2

TRAINING WHEELS

x2

WASHERS

x2

TRAINING WHEEL

BOLTS

x2

ALIGNMENT TAB

(DRIVE-SIDE)

ALIGNMENT TAB

(NON DRIVE-SIDE)

3

C

A

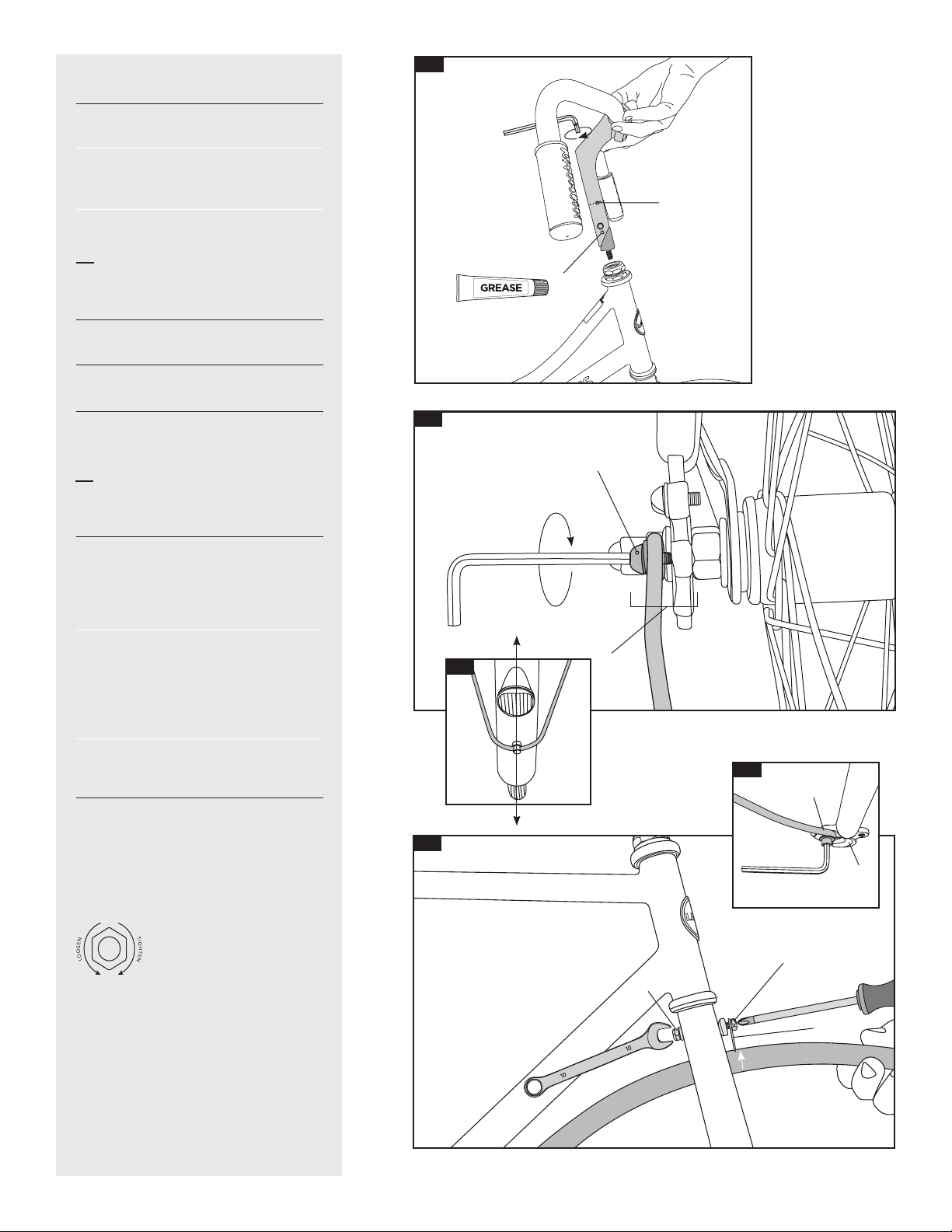

1. Stem Installation

1.1 Apply a small amount of grease around

the bottom 1.5” (35mm) of the stem (A).

Insert stem into the steerer tube so

that the minimum insertion line (B)

is not visible.

Tighten with the 6mm Allen wrench (C).

Torque Requirement: 20-23Nm.

2. Rear Fender Brace Installation

2.1 Unthread the rear-most bolts from the

rear dropouts using a 4mm hex wrench (A).

2.2 Center fender brace at back of

fender (B).

2.1 Thread 4mm bolts through the brace

eyelets and screw them back into the

dropouts (C). Torque Requirement: 4-5Nm.

3. Front Fender Installation

3.1 Unscrew the bolt at the front of the fork

crown (B) with a philips head screwdriver

while holding the nut on the back side of

the fork crown (A) with a 10mm wrench.

Do not misplace the crescent washer.

Insert bolt through the fender mounting

flange (C) and the crescent washer

with curved side facing the fork crown.

Place flat washer over the end of the bolt

followed by threading on the nut (A) then

tighten lightly.

Push the fender upward until it stops and

then completely tighten the nut.

Torque Requirement: 6.5-9Nm

3.2 Unthread bolts from the fork

drop outs (D) using a 4mm hex wrench.

Center fender brace. Thread bolts

through the brace eyelets (E) and

screw them back into the dropouts.

Torque Requirement: 4-5Nm.

A

B

C

C

3.1

2.1

(Applicable to Earlier Year Models)

(Applicable to Earlier Year Models)

E

3.2

2.2 B

D

4

1.1

B

A

C

1.1

5

4. Front Wheel Installation

4.1 Use 15mm wrench to loosen the nuts

on the front wheel enough to slide the axle

(A) into the fork dropouts (B). Make sure to

seat the axle completely in the dropouts.

Insert bent tab of axle washer (C) into

small hole at the top of the dropouts.

Make sure washer is on the outside of the

dropouts.

4.2 Tighten the axle nuts (D). Torque

Requirement: 30-45Nm.

5. Stem/Handlebar Adjustment

5.1 Using a 6mm hex wrench, loosen the

bolt in the front of the stem (A) and adjust

the handlebars so that they are level then

re-tighten. Torque Requirement: 10-12Nm.

5.2 Check to make sure the stem is in line

with the front wheel (C) and that the

minimum insertion line (B) is not visible.

Use the 6mm hex wrench to loosen the

stem, adjust and then tighten. Torque

Requirement: 20-23Nm.

5.1

0°

C

5.2

A

B

5.2

C

D

A

B

4.1 4.2

7.1

B

AC

D

0°

6. Pedal Installation; READ FIRST!

(POTENTIAL FOR DAMAGE IF

INSTALLED INCORRECTLY!)

6.1 Pedals are side-specific. Check the

ends of the axles (A) to identify which

side of the bicycle to install them in.

R = Side of bicycle with chain.

Apply a small amount of grease to the

pedal threads.

6.2 Install the pedal marked Rby turning

the axle CLOCKWISE.

Install the pedal marked Lturning the

axle ANTI-CLOCKWISE.

Tighten the pedal axles fully with the

15mm wrench. Torque Requirement:

28-37Nm.

7. Seat Post Installation

7.1 Apply a small amount of grease around

the bottom 1.5” (35mm) of the seat post (A)

and insert the seat post into the seat tube

so that the minimum insertion line (B) is

not visible.

7.2 Align the saddle with the bicycle’s top

tube as shown.

7.1 Tighten down the seat post clamp (C)

using the appropriate hex wrench.

Torque Requirement: 4.5-6Nm.

7.1 Check to make sure that the saddle is

level (D). If it is not, use a 14mm wrench

to loosen the saddle clamp (E), adjust the

saddle, and re-tighten.

Torque Requirement: 20-27Nm.

8. Bell + Reflector Installation

8.1 Using a Philips screwdriver, remove

the bell skrew (A) and clamp the bell on

the left side handle bar near the grip with

the striker positioned on the inside. Then

re-insert the screw and tighten.

Be careful not to lose the square nut (B)

that should be inserted from the side of

the bell clamp.

8.2 Using a Philips screwdriver, clamp the

white reflector on the stem or handlebar

and tighten down. Adjust the reflector

lens so that the lens is perpendicular to

the road.

6.1

7.2

A

8.2

(Note: Some bike models may not include bell)

6

(SIDE-SPECIFIC THREADING ON PEDALS)

6.2

8.1

B

A

E

9. Tire Inflation

Tire information can be found on the

side-walls of your tires – you should be

able to see tire size (e.g. 16x1.50) and

recommended inflation (e.g. 40-65 PSI).

Tire pressure should be checked

before each ride to help prevent

unnecessary flats.

* Flat tires can occur for a varity of

reasons including improper inflation

and puncture from road debris. As such,

punctures are not covered by warranty.

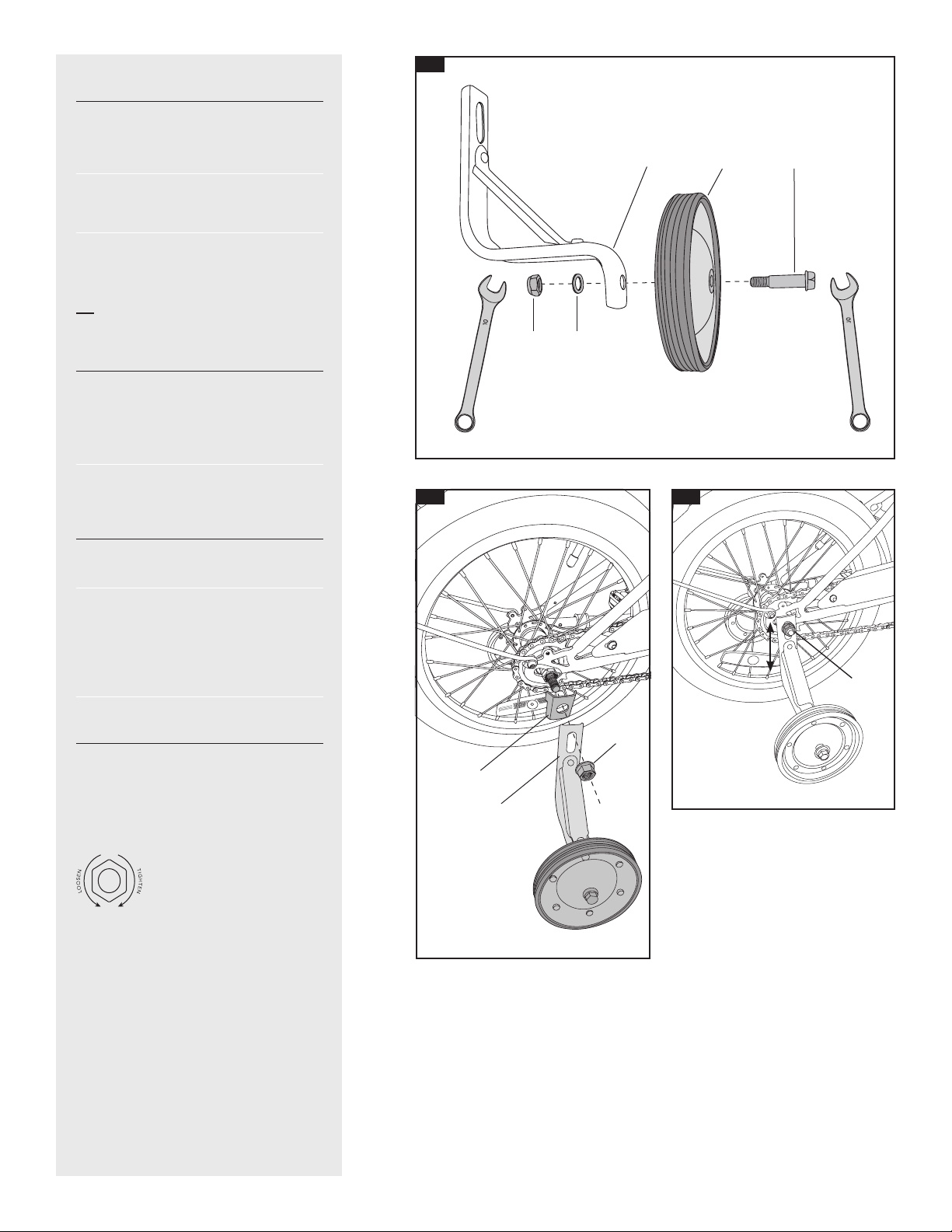

10. Training Wheel Assembly

(Applicable to 16” bike models)

10.1 Assemble the trainings wheels by

inserting bolt (A) through training wheel

(B) then through the training wheel

bracket (C). Slide Washer (D) over threads

of bolt followed by locking nut (E).

Tighten training wheel assembly using

a 12mm wrench on bolt (A) and a 13mm

wrench on locking nut (E). Check to be

sure wheel spins freely.

10.2 Remove axle nuts (C) from both sides

of rear axle with a 15mm wrench.

Insert alignment tab (A) over the axle

slotting the extended tougue of tab into

the dropout gap. Note: these tabs are side

specific. Drive-side tab has toungue on

upper left corner. Non-drive side tab has

toungue on upper right corner.)

Attach training wheel assembly bracket (B)

over the axle and secure with axle nut (C).

10.3 Adjust hight of training wheels

evenly on both sides to 1/4”-1/2” above the

ground. Tighten axle nut (C) with a 15mm

wrench.

Torque Requirement: 30-45Nm

ABC

DE

7

10.1

10.2 10.3

C

A

B

C

Stem

Looking down at the handlebars,

ensure that the stem is in line with

the front wheel and the minimum

insertion line is not visible. Once it

is, tighten the 6mm bolt securely.

Torque Requirement: 20-23Nm.

To make sure that the stem is

tightened enough, hold the front wheel

in place and twist the handlebars.

If the handlebars move, re-align the

stem and tighten the bolt to spec.

Handlebar

Looking at the handlebars from the

side, ensure that they are level with the

ground. Once level, tighten the 6mm

bolt securely.

Torque Requirement: 10-15Nm

To make sure that the handlebars are

properly tightened, lean down on them

with significant pressure. If they move,

loosen the 6mm bolt, reposition the bar

and re-tighten the bolt to spec.

Final Check

Saddle

Set saddle height slightly below

your hips. Tighten seatpost clamp.

Torque Requirement: 4.5-6Nm.

Make sure saddle clamp is tightened.

Torque Requirement: 20-27Nm.

Wheels

Check front and rear axle nuts for

tightness. Torque Requirement:

30-45Nm.

General

Test ride your Linus to ensure that

the hub is shifting correctly, that

the brakes are engaging quickly

and securely, and the fenders and

chain guard do not rub or make

unnecessary noise.

8

This manual suits for next models

4

Table of contents

Other Linus Bicycle manuals