05-3028-C

Section 2. Overview of the LCM-140

The LINX Cooler Module (LCM) Drinking Water Systems employs an ion exchange process which uses electricity rather than

chemicals for operation. LINX technology does not release chemicals to the environment and it conserves water compared to

other drinking water systems that provide similar water quality.

LINX technology provides several important benefits:

High flow rates: up to 0.5 gallons/minute (gpm) when installed without an external tank, and up to 1.0 gpm when

installed with an external tank.

Wastes 90% less water than reverse osmosis drinking water systems under typical usage conditions.

The Dial-a-Taste control allows adjustment of product water mineral level for optimum taste.

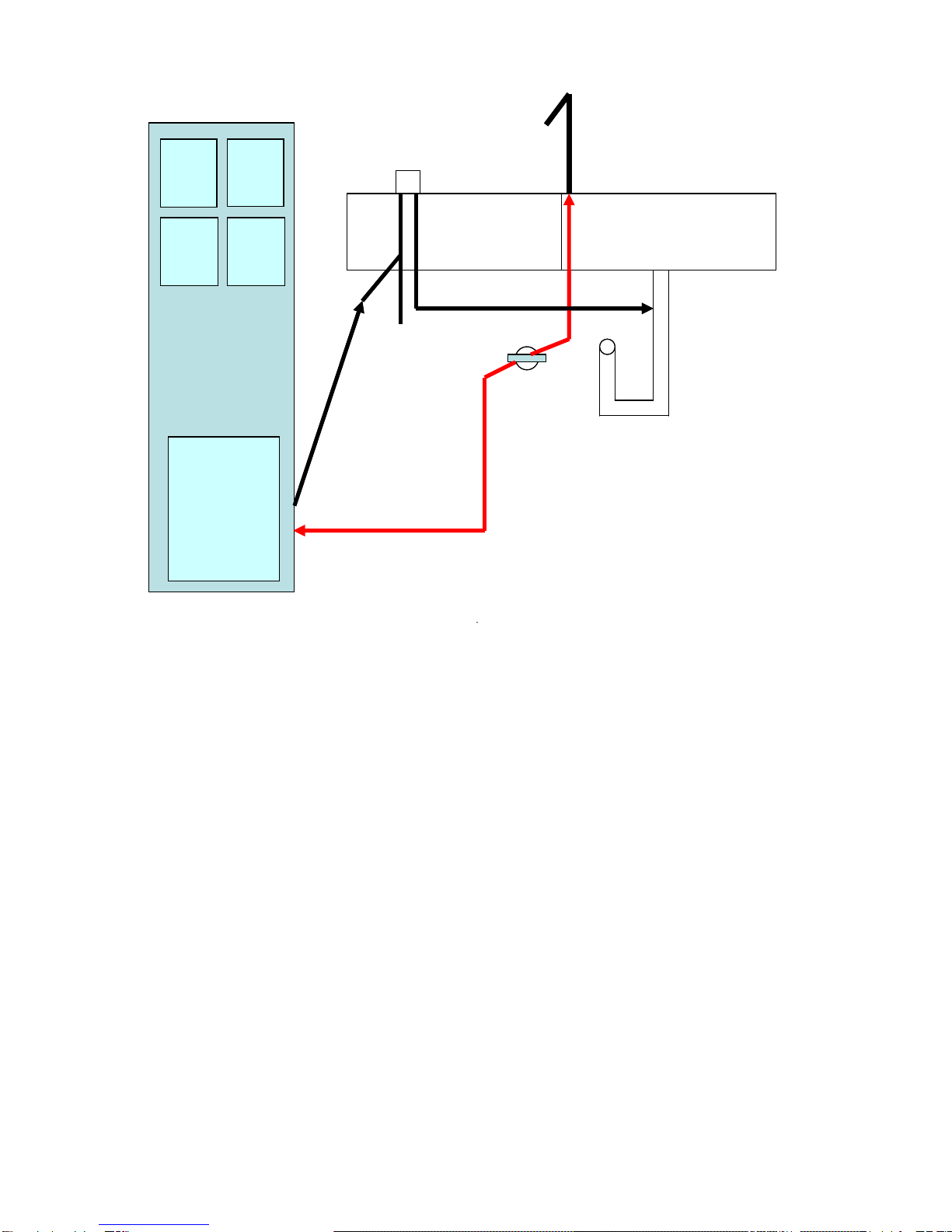

The LCM systems include:

One LINX 100 Sediment pre-filter (nominal 5 micron) to reduce particles and cloudiness

Two LINX 100 TDS cartridges to reduce nitrate/nitrite contaminants for healthier water and other total dissolved

solids (TDS) for better taste

One LINX 100 or 110 Carbon post-filter (GAC) to further improve taste

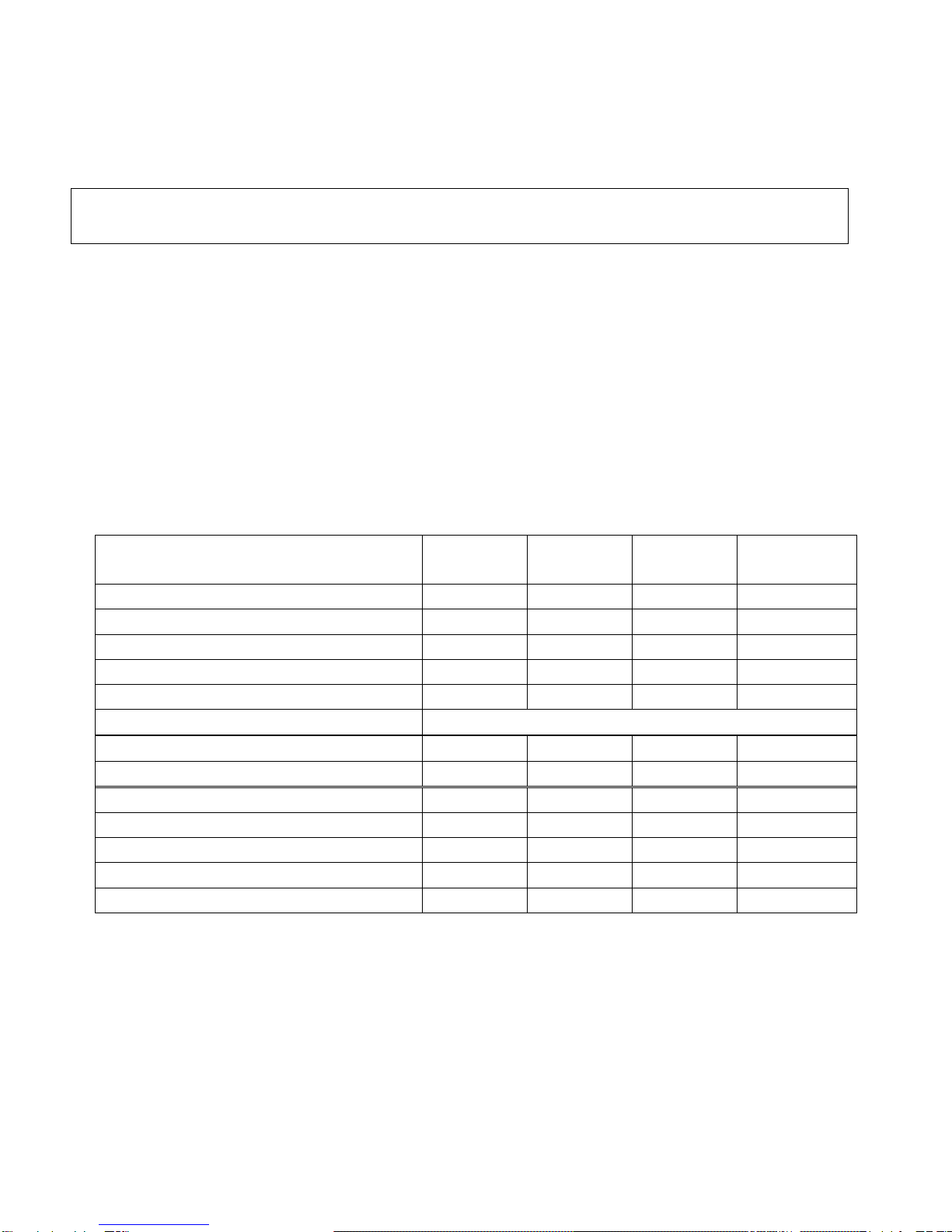

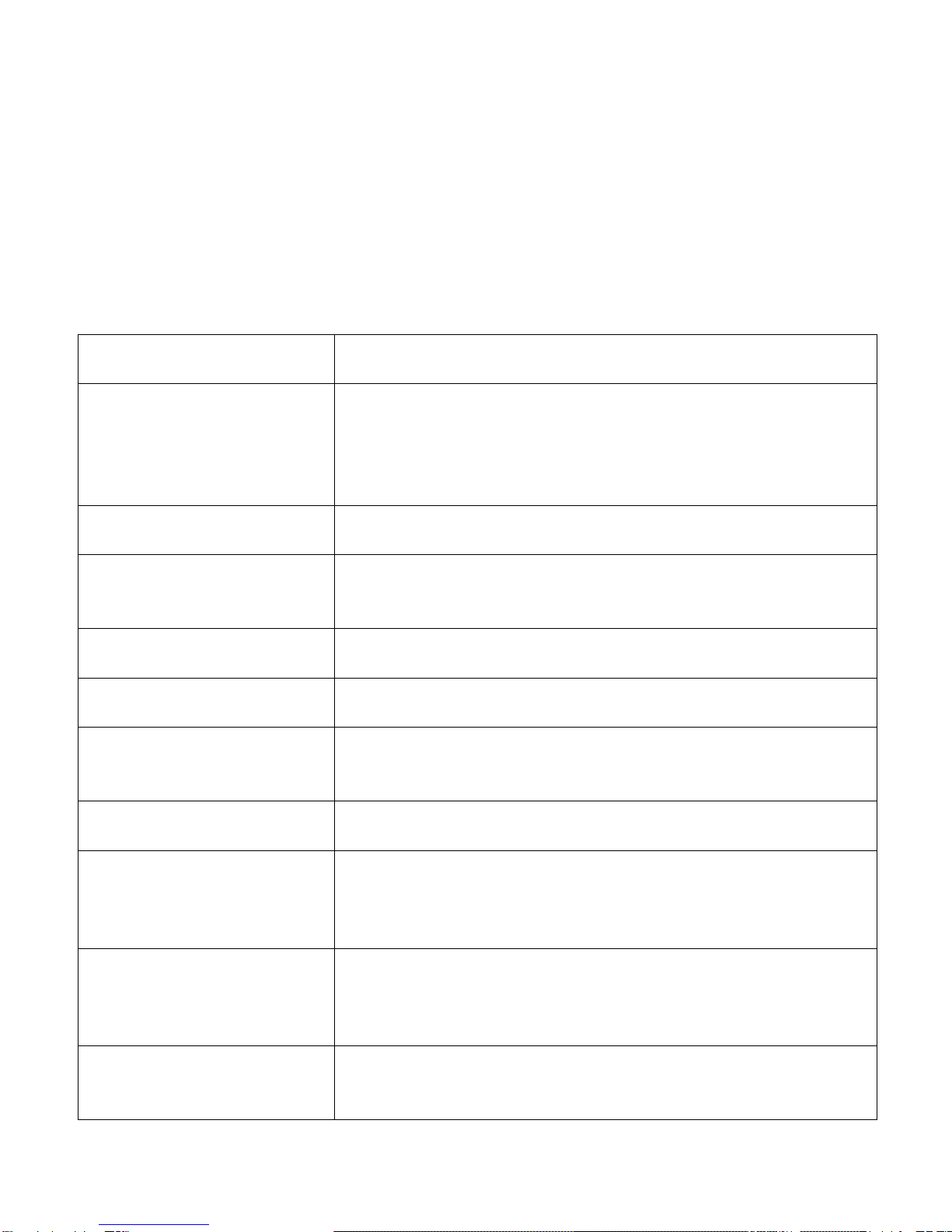

Specification:

Feed Water Quality: Potable water with maximum TDS of 1000 ppm, <20 grains of hardness (340

ppm hardness as CaCO3), pH 4 –10; microbiologically safe

Feed Water Pressure: 20-100 psi (130-690 kPa)

Feed Water and Operating Temperature: 33-100˚F (1-40˚C)

Operation Mode: Parallel LINX cell deionization; water available during regeneration

Regeneration: 34 minutes (17 minutes each cell)

TDS Rejection* (Maximum Dial): ≥85% TDS reduction

LCM Water Output Flow Rate: 0-600 ppm TDS feed: 0.5 gpm at ≥40 psi

600-800 ppm: 0.25 gpm (see Replacement Parts list for flow restrictor)

800-1000 ppm: 0.15 gpm (see Replacement Parts list for flow restrictor)

Flow Rate with External Tank: 1.0 gpm, maximum (LCM-140T Model only)

Water Output Volume per Cycle: 0-400 ppm TDS feed: 3.0 gallons per 34 minute regeneration cycle

400-1000 ppm TDS feed: 1.5 gallons per 34 minute regeneration cycle

Rated Capacity: 3 gallons/cycle

Rated Life**: 650 gallons for LINX 100 Sediment and LINX 100 or 110 Carbon filters

1300 gallons for two (2) LINX 100 TDS cartridges

Warranteed Water Output per Day: ≤25 gallons (if product exceeds 25 gallons per day on average, the warranty is

no longer valid)

Water Recovery: 0-400 ppm TDS feed: 70%; 401-1000 ppm TDS feed: 55%

Operating Voltage, Current: 100-120 VAC, 50/60 Hz, 6 A

Outside Dimensions: 12.2 in (deep) x 11.0 in (wide) x 14.0 in (high)

*TDS reduction was tested and verified at an independent laboratory: Pace Analytical Services, Inc.

**The rated lives of LINX 100 TDS cartridges and Sediment/Carbon filters is based on extensive testing by the manufacturer.

The LINX Cooler Modules conform to NSF/ANSI 53 for nitrate/nitrite reduction as verified and substantiated by test data.