Lippert Components Power Gear User manual

Electric Motor

Slide-out

OWNER'S MANUAL

Rev: 04.04.19 Page 2 CCD-0001615

Introduction

The electric slide-out system is designed to provide years of trouble free operation and reflects the latest

state-of-the-art technology.

NOTE: Information for this document was obtained from Power Gear manual #82-S0380 Rev. 0B issued

May 2008. All information has been updated for current practices.

Major Components

The slide-out system is a rack and pinion design operated by a 12 V DC electric motor.

• Inner rail assemblies are designed to support the room weight.

• The 12 V DC gear motor will operate the room using power from the on board unit battery.

• Slide-out systems are equipped with a manual override that extends or retracts the room in the event of a

loss of power.

Safety

TABLE OF CONTENTS

Introduction 2

Major Components 2

Safety 2

Operation 3

Extending the Room 3

Retracting the Room 3

Manually Overriding the Slide-Out 3

Maintenance 5

Read, study and understand all instructions in this manual before operating the electric

motor driven slide-out system.

Always keep away from the slide-out rails when the room is being operated. The gear assembly may

pinch or catch on loose clothing causing personal injury.

Always utilize a room locking device on the slide-out room during storage and transportation.

Failure to follow these instructions could result in serious injury or death.

Always make sure that the slide-out room path is clear before and during operation

of the slide-out room.

Rev: 04.04.19 Page 3 CCD-0001615

Operation

Extending the Room

1. Level the coach.

2. Verify the battery is fully charged and hooked up to the electrical system.

3. If so equipped, remove the transit bars.

4. Make sure the room path is clear, both inside and outside the coach.

5. Check the slide-out awning. Some awnings must be manually unlocked before operating the slide-out.

6. Press and hold the IN/OUT switch in the OUT position until the room is fully extended and stops

moving.

7. Release the switch, which will lock the room into position.

Retracting the Room

1. Verify coach is level.

2. Verify the battery is fully charged and hooked up to the electrical system.

3. Make sure the room path is clear, both inside and outside the coach.

4. Press and hold the IN/OUT switch in the IN position until the room is fully retracted and stops moving.

5. Release the switch, which will lock the room into position.

6. Check the slide-out awning. Some awnings must be manually locked before traveling.

7. If so equipped, install transit bars.

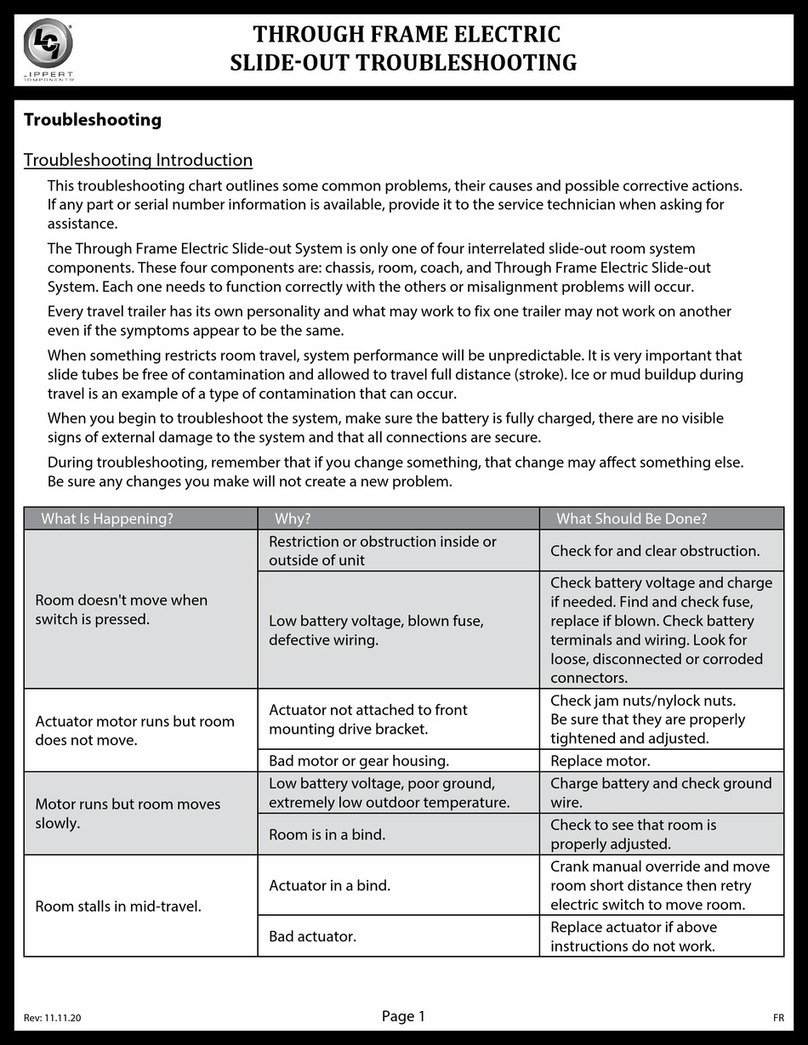

Manually Overriding the Slide-Out

Your slide-out system is equipped with a manual crank override that extends or retracts the room in the

event of a loss of power (Fig.1.) The crank mode uses a ¾" ratchet or wrench to turn the ¾" hex head

override nut located on the motor's gear box (Fig. 3).

NOTE: Optionally, it is permissible to use an adjustable wrench on the square drive shaft to crank the room

in or out (Fig. 2).

If the room does not move when the switch is pressed, check the following:

• Battery is fully charged and connected.

• The transit bars are removed.

• All system fuses/circuit breakers and relays are good.

Override

Location

Override

Location

Override

Locations

Fig. 1

Front

Rear

Main Room Slide Bedroom Slide, Diesel

Bedroom Slide, Gas

Tire

Tire Tire

Tire

Tire

Tire

Rev: 04.04.19 Page 4 CCD-0001615

After the previous items have been checked and the room still does not move when the slide-out switch is

pressed, follow these simple steps to manually override the slide-out room.

1. Locate applicable slide-out motor from Figure 1.

A. The motor is located in the top of the center storage compartment under the slide-out room.

B. A bedroom slide-out motor will be mounted to the rail assembly.

2. In slide-out motors built after 2009, brake levers are equipped with a spring lock.

A. Do not remove rubber boot when engaging or releasing the brake lever.

B. When viewed from end of motor (Fig. 4), depress the spring lock lever on the right hand side of

the boot cover.

NOTE: In slide-out motors built prior to 2009, brake levers are not equipped with a spring lock.

C. Rotate the override lever counterclockwise approximately 30 degrees until the brake lever stops

against the brake's set screw while contacting with the spring lock.

3. The room is now free to move.

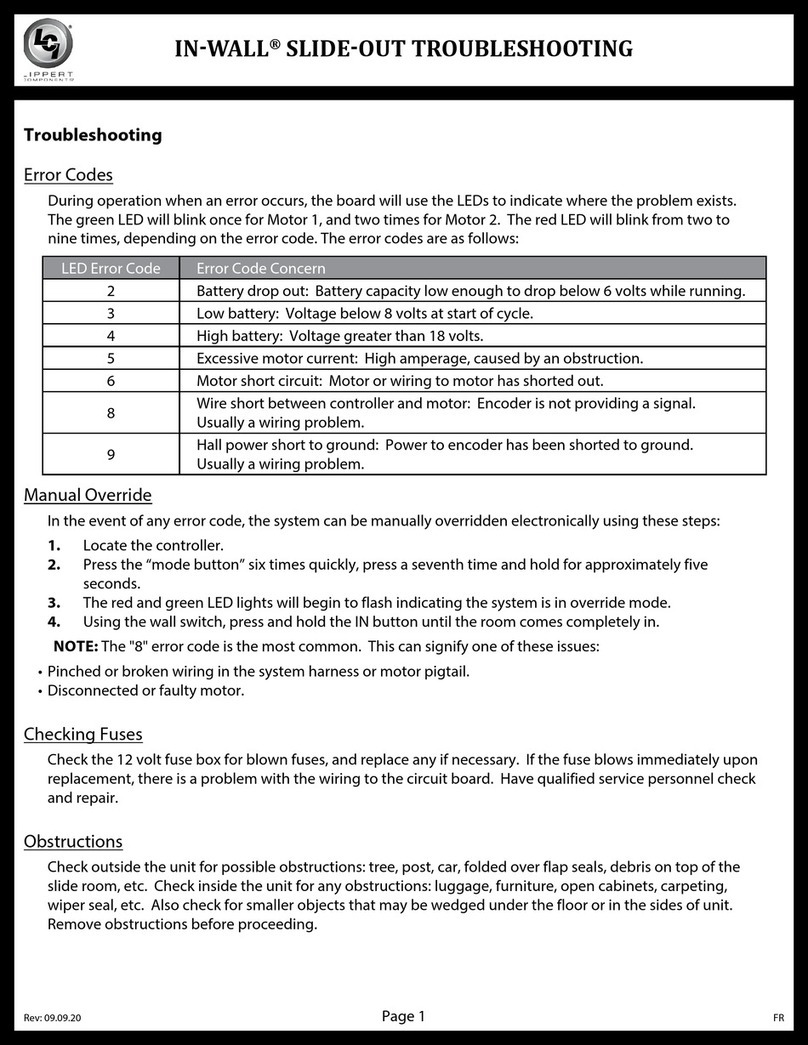

4. Locate the manual override on the end of a rail assembly (Fig. 2). It is also permissible to use an

adjustable wrench on the square drive shaft (Fig. 2) to crank the room in or out.

5. Check the slide-out awning. Some awnings must be manually unlocked before operating.

6. Using a 3/4" wrench or ratchet, crank the room either in or out completely, depending on need.

7. When the room is fully in or out, apply pressure to the wrench or ratchet, then return the motor brake

lever to the "Engaged" position. This will ensure the room is locked into a sealed position.

When the motor brake is disengaged, the slide-out room will not lock in place; therefore, the room will

not be sealed. When the room has been manually retracted, be sure to install the transit bars and return

the motor brake lever to its normal “engaged” position in order to seal and lock the room into position.

Do not remove rubber boot. Removal of boot will void manufacturer's warranty.

Fig. 2

Override

Override

Square

Drive

Shaft

Motor

Brake

Release

Lever

Rev: 04.04.19 Page 5 CCD-0001615

8. Again, check the slide-out awning. Some awnings must be manually locked before traveling.

9. If so equipped, re-install transit bars.

10. Take the coach to an authorized dealer for service.

Maintenance

The slide-out system has been designed to require very little maintenance. To ensure the long life of the

slide-out system read and follow these few simple procedures.

• When the room is out, visually inspect the inner slide rail assemblies. Check for excess build-up of dirt or

other foreign material; remove any debris or items that may be present.

• If the system squeaks or makes any noises, it is permissible to apply a light coating of silicone spray or

lithium grease to the roller and bearing sleeve ID. Remove any excess lubricant so that dirt or debris do not

build-up.

• DO NOT lubricate the slide-out drive gears, gear racks, or roller O.D. as this will attract dirt or debris.

Do not work on the slide-out system unless the battery is disconnected.

Motor

Leads

¾" Hex.

Override

Fig. 3

Rotate approximately 30

degrees counterclockwise

to release motor brake.

Fig. 4

30°

0°

The contents of this manual are proprietary and copyright protected by Lippert Components, Inc. (“LCI”).

LCI prohibits the copying or dissemination of portions of this manual unless prior written consent from an

authorized LCI representative has been provided. Any unauthorized use shall void any applicable warranty.

The information contained in this manual is subject to change without notice and at the sole discretion of LCI.

Revised editions are available for free download from lci1.com.

Please recycle all obsolete materials.

For all concerns or questions, please contact

Lippert Components, Inc.

Other manuals for Power Gear

1

Table of contents

Other Lippert Components Bicycle manuals