Rev: 05.10.2023 Page 3 CCD-0007494

Failure to follow instructions provided in this manual may result in death, serious personal injury

and/or severe product and property damage, including voiding of the component warranty.

The "WARNING" symbol above is a sign that a procedure has a safety risk involved and may cause

death or serious personal injury if not performed safely and within the parameters set forth in this

manual.

Safety

Read and understand all instructions before installing or operating this product. Adhere to all safety labels.

Local building codes may impose additional requirements that may supersede the installation instructions

in this manual. Be sure to check with the local municipality for code adherence. Determining the

acceptability of alternate installation methods is solely the responsibility of the installer.

This manual provides general instructions. Many variables can change the circumstances of the instructions,

i.e., the degree of difficulty, operation and ability of the individual performing the instructions. This

manual cannot begin to plot out instructions for every possibility, but provides the general instructions,

as necessary, for effectively interfacing with the device, product or system. Failure to correctly follow the

provided instructions may result in death, serious personal injury, severe product and/or property damage,

including voiding of the Lippert limited warranty.

Be sure turn o power before beginning any electrical work. All electrical work must be carried out

by qualied personnel and conform to applicable electrical codes and standards. Please consult the

wiring diagram to locate any wiring prior to any drilling or any installation procedures.

Additional information about this product can be obtained from lci1.com/support or by downloading

the free LippertNOW app. The app is available on Apple App Store® for iPhone® and iPad® and also on

Google Play™ for Android™ users.

Apple App Store®, iPhone®, and iPad® are registered trademarks of Apple Inc.

Google Play™ and Android™ are trademarks of Google Inc.

For information on the assembly or individual components of this product, please visit:

https://support.lci1.com/gp-llc-awnings-manuals.

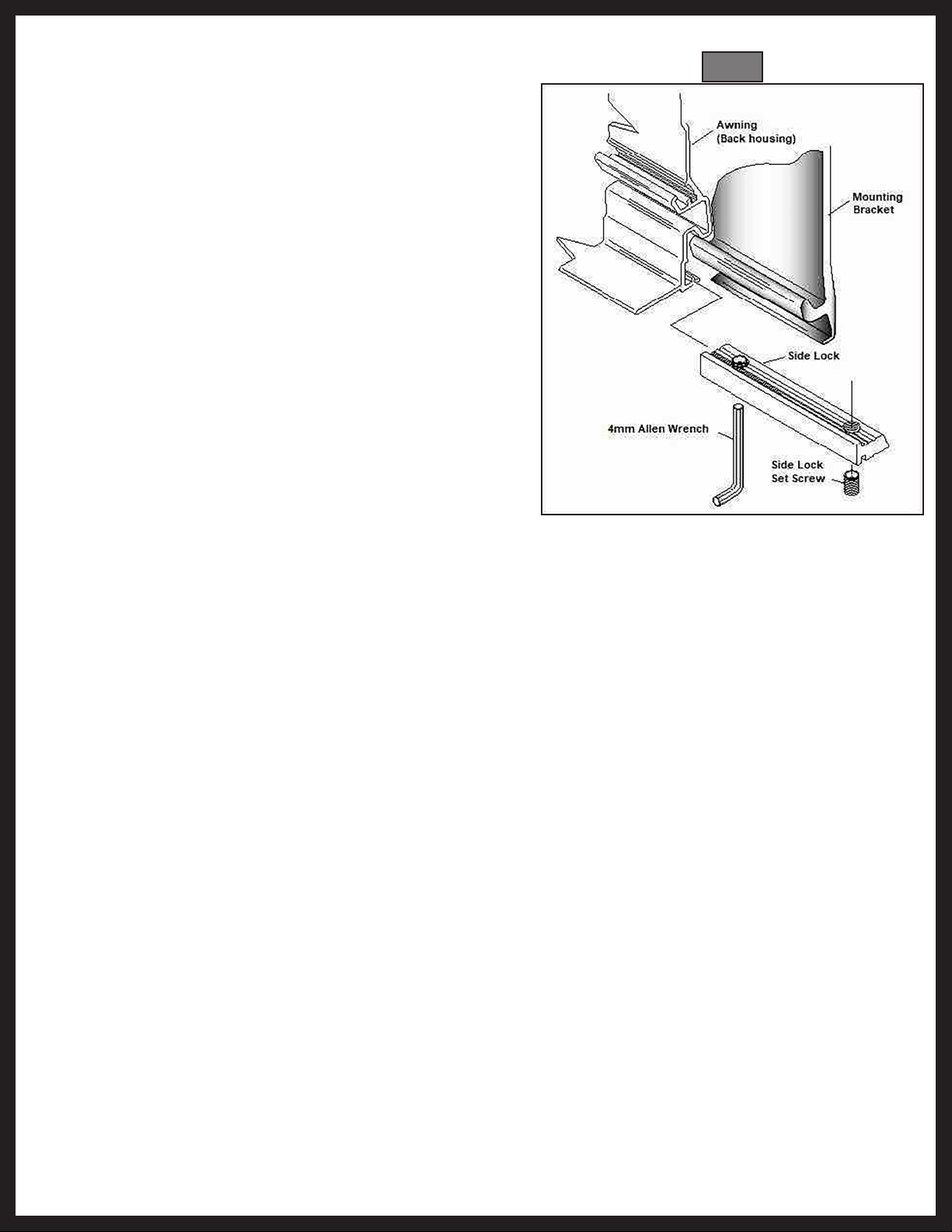

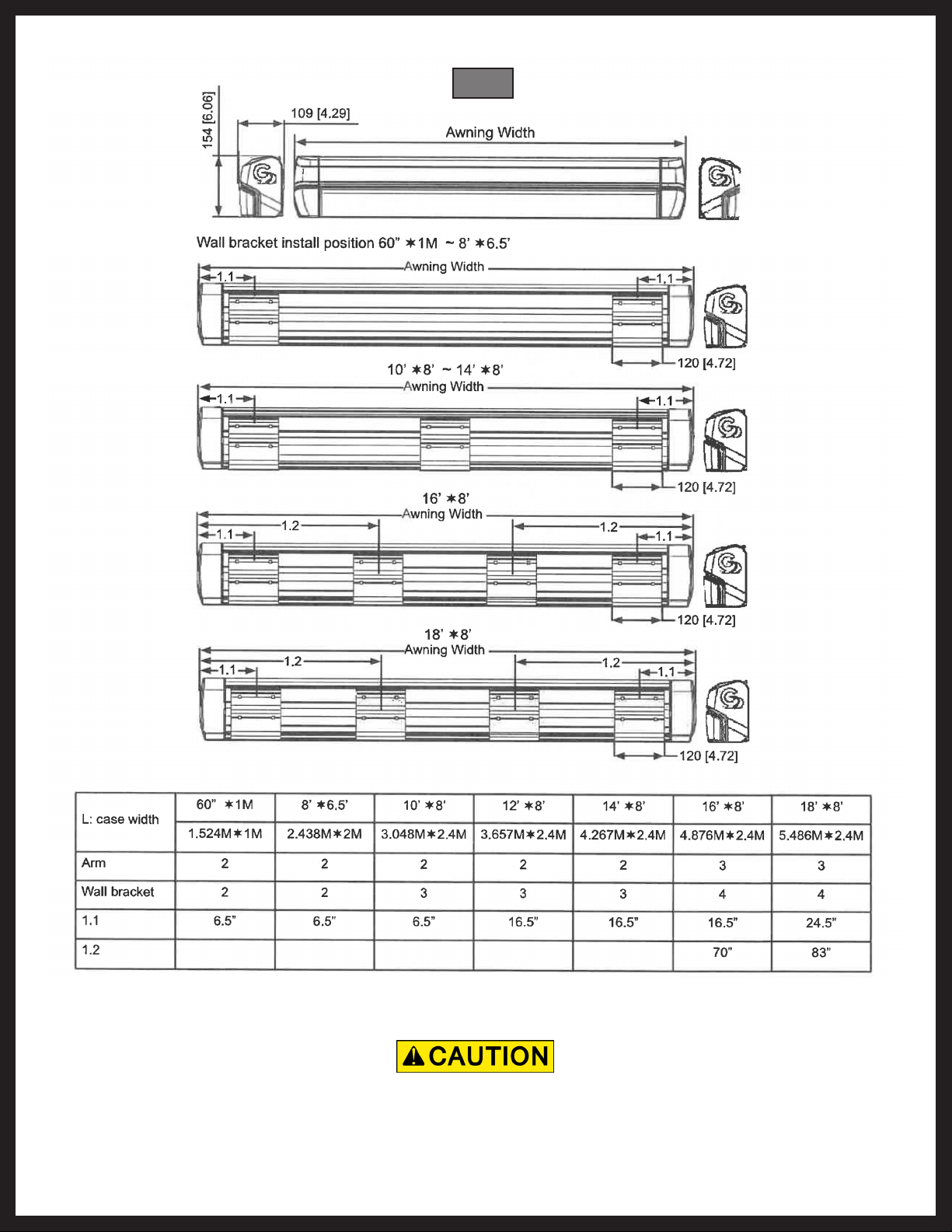

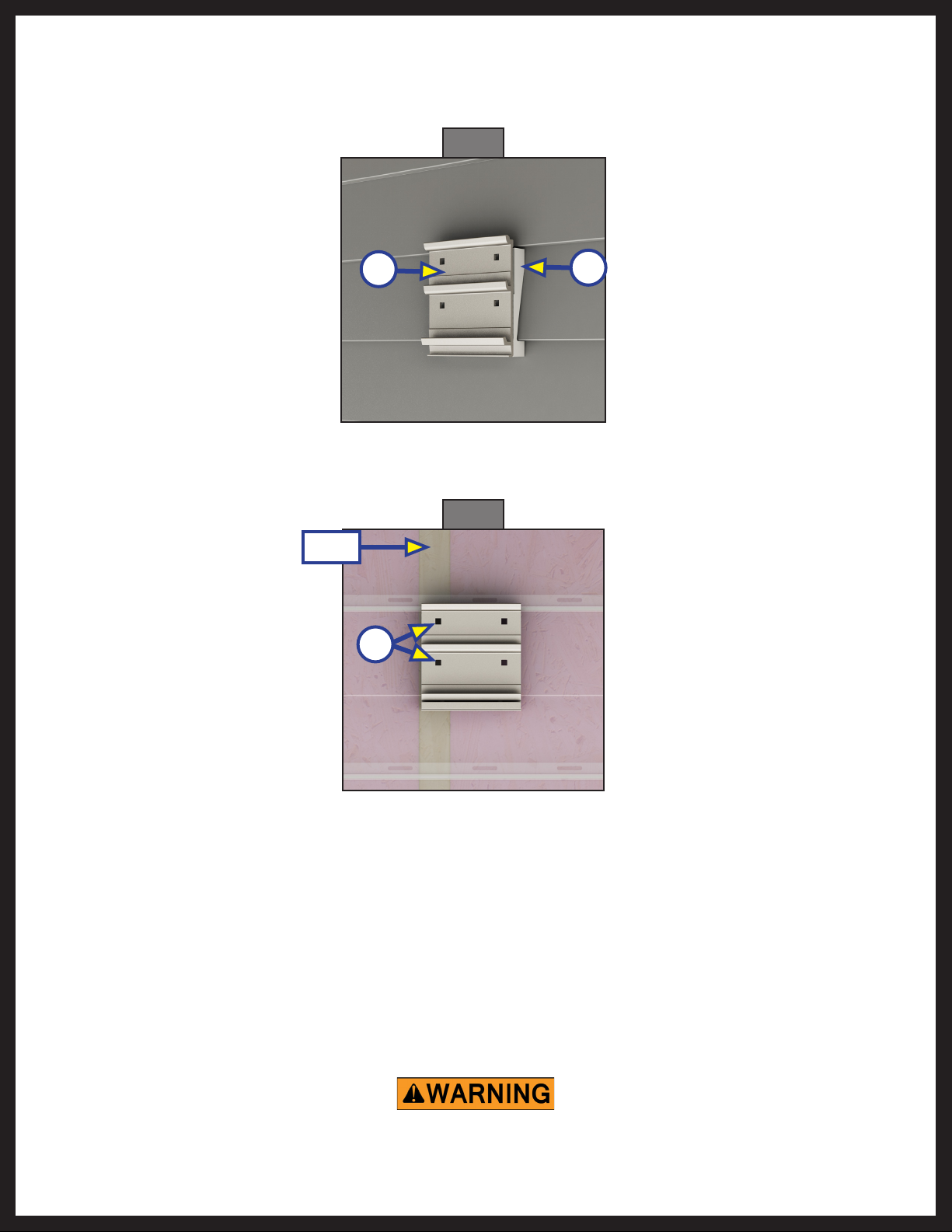

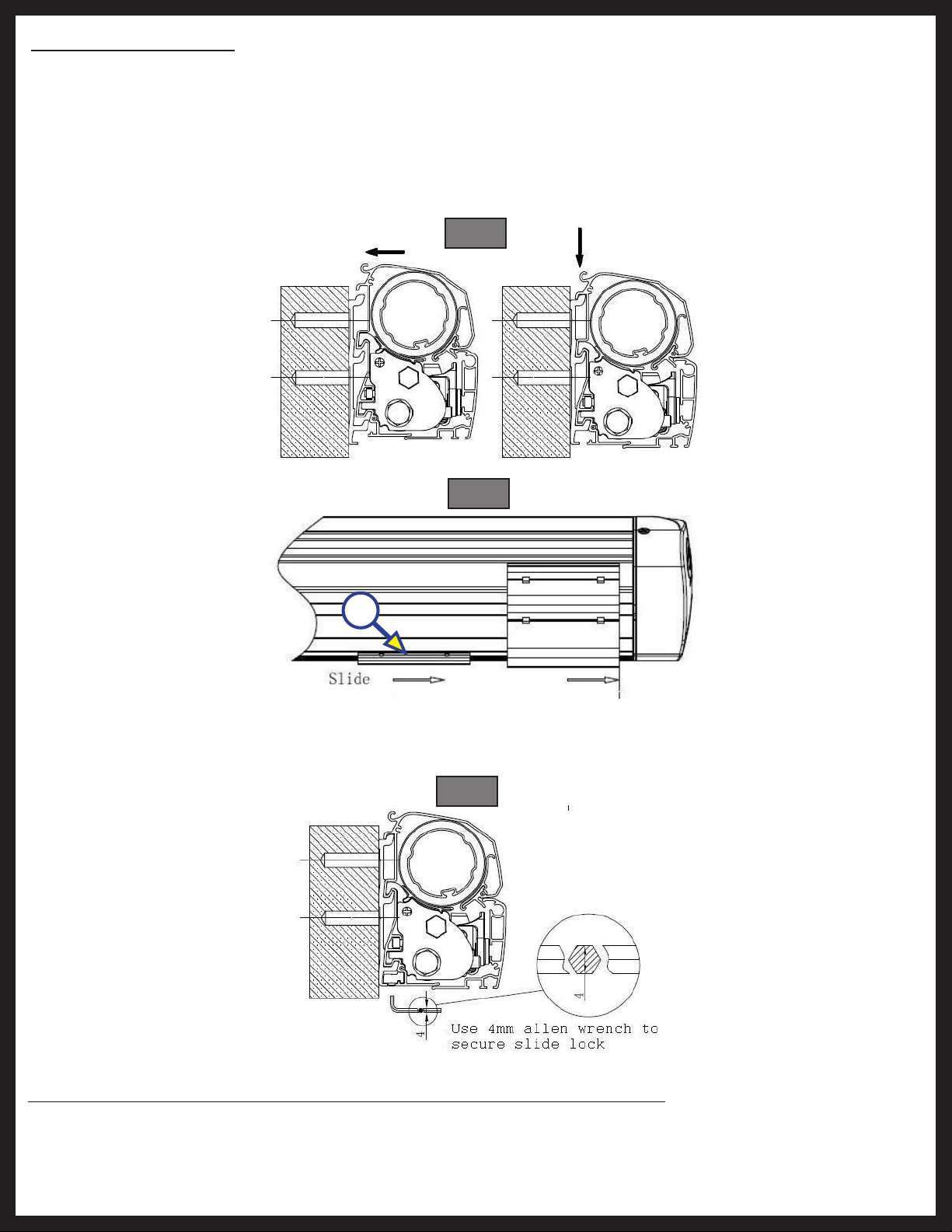

NOTE: Images used in this document are for reference only when assembling, installing and/or operating

this product. Actual appearance of provided and/or purchased parts and assemblies may differ.

Always wear eye protection when performing service, maintenance or installation procedures.

Other safety equipment to consider would be hearing protection, gloves and possibly a full face

shield, depending on the nature of the task.

The “CAUTION” symbol above is a sign that a safety risk is involved and may cause personal injury

and/or product or property damage if not safely adhered to and within the parameters set forth

in this manual.