a

Table of Contents

1. INTRODUCTION................................................................................................................................................... 1

1.1 SCOPE...................................................................................................................................................... 1

1.2 APPLICABLE EUROPEAN DIRECTIVES/NORMS................................................................................... 1

1.3 INTENDED USE........................................................................................................................................ 1

1.4 SYMBOLS DISPLAYED ON THE STERILIZER........................................................................................ 2

1.5 GENERAL AND SAFETY RECOMMENDATIONS.................................................................................... 2

2. UNPACKING ........................................................................................................................................................ 3

2.1 UNPACKING THE STERILIZER................................................................................................................ 3

2.2 STANDARD ACCESSORIES .................................................................................................................... 3

3. UNIT DESCRIPTION ............................................................................................................................................ 4

3.1 FRONT VIEW............................................................................................................................................ 4

3.2 SERVICE DOOR ....................................................................................................................................... 4

3.3 REAR VIEW............................................................................................................................................... 5

3.4 DESCRIPTION OF THE INTERNAL WATER TANKS............................................................................... 6

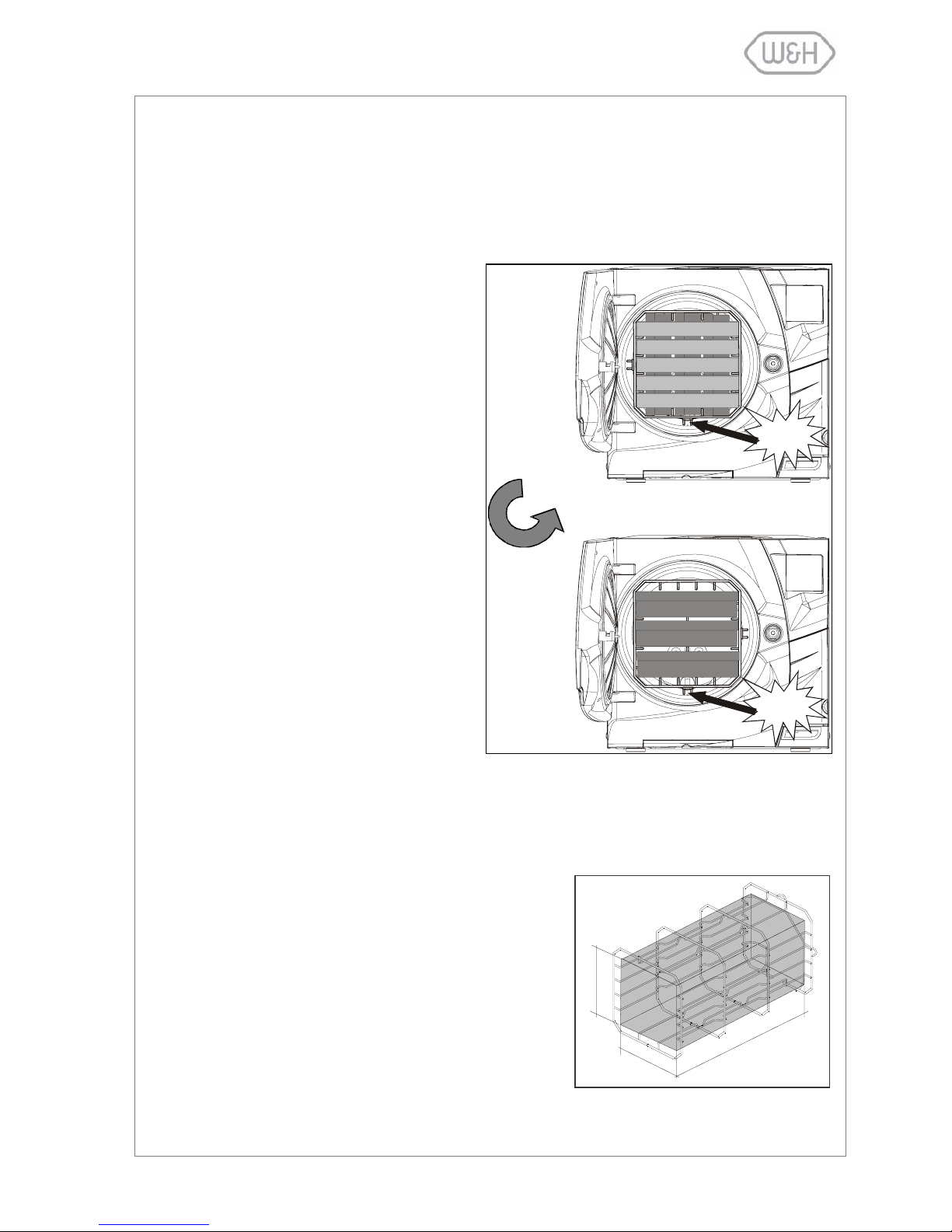

3.5 CHAMBER RACK...................................................................................................................................... 7

3.6 USABLE SPACE IN THE CHAMBER........................................................................................................ 7

4. INSTALLATION.................................................................................................................................................... 8

4.1 SETUP....................................................................................................................................................... 8

4.1.1 Securing the sterilizer with a safety bracket................................................................................. 8

4.2 ELECTRICAL POWER SUPPLY............................................................................................................... 9

4.3 PRINTER (optional)................................................................................................................................... 9

4.4 LABEL PRINTER (optional)..................................................................................................................... 10

4.5 DEMINERALIZER (optional).................................................................................................................... 11

4.5.1 Connecting an external water supply system (demineralizer).................................................... 11

4.6 CONTINUOUS DRAINING (optional) ...................................................................................................... 11

4.6.1 Connecting the drain tube.......................................................................................................... 11

5. GETTING STARTED .......................................................................................................................................... 12

5.1 THE USER INTERFACE ......................................................................................................................... 12

5.2 INITIAL WARNINGS AND SLEEP MODE............................................................................................... 13

5.3 DATE-CLOCK SETTING......................................................................................................................... 13

5.4 FILLING OF THE CLEAN WATER TANK................................................................................................ 14

5.4.1 Manual filling.............................................................................................................................. 14

5.4.2 Automated water supply (optional) ............................................................................................ 14

5.5 DRAINING OF THE USED WATER TANK.............................................................................................. 15

5.5.1 Manual draining......................................................................................................................... 15

5.5.2 Continuous draining................................................................................................................... 15

5.6 MEMORY CARD (optional for 300 Series) .............................................................................................. 15

5.6.1 Inserting / removing the memory card ....................................................................................... 15

6. PROGRAMMING ................................................................................................................................................ 16

6.1 SETUP MENU......................................................................................................................................... 16

6.1.1 Language................................................................................................................................... 17

6.1.2 Sleep mode................................................................................................................................ 17

6.1.3 Printer........................................................................................................................................ 17

6.1.4 Label printer (available with LisaSafe option) ............................................................................ 18

6.1.5 Automatic printing (available with LisaSafe option).................................................................... 18

6.1.6 Manual printing (available with LisaSafe option)........................................................................ 19

6.1.7 Storage time/weeks (available with LisaSafe option)................................................................. 19

6.1.8 User name................................................................................................................................. 20

6.1.9 Date-Clock setting ..................................................................................................................... 20

6.1.10 Date format................................................................................................................................ 21

6.1.11 Clock format............................................................................................................................... 21

6.1.12 Display contrast......................................................................................................................... 21

6.1.13 Display backlight........................................................................................................................ 22

6.1.14 Acoustic tones ........................................................................................................................... 22

6.2 DELAYED CYCLE START ...................................................................................................................... 23