- 18 - - 19 -

11.Variable dropper post

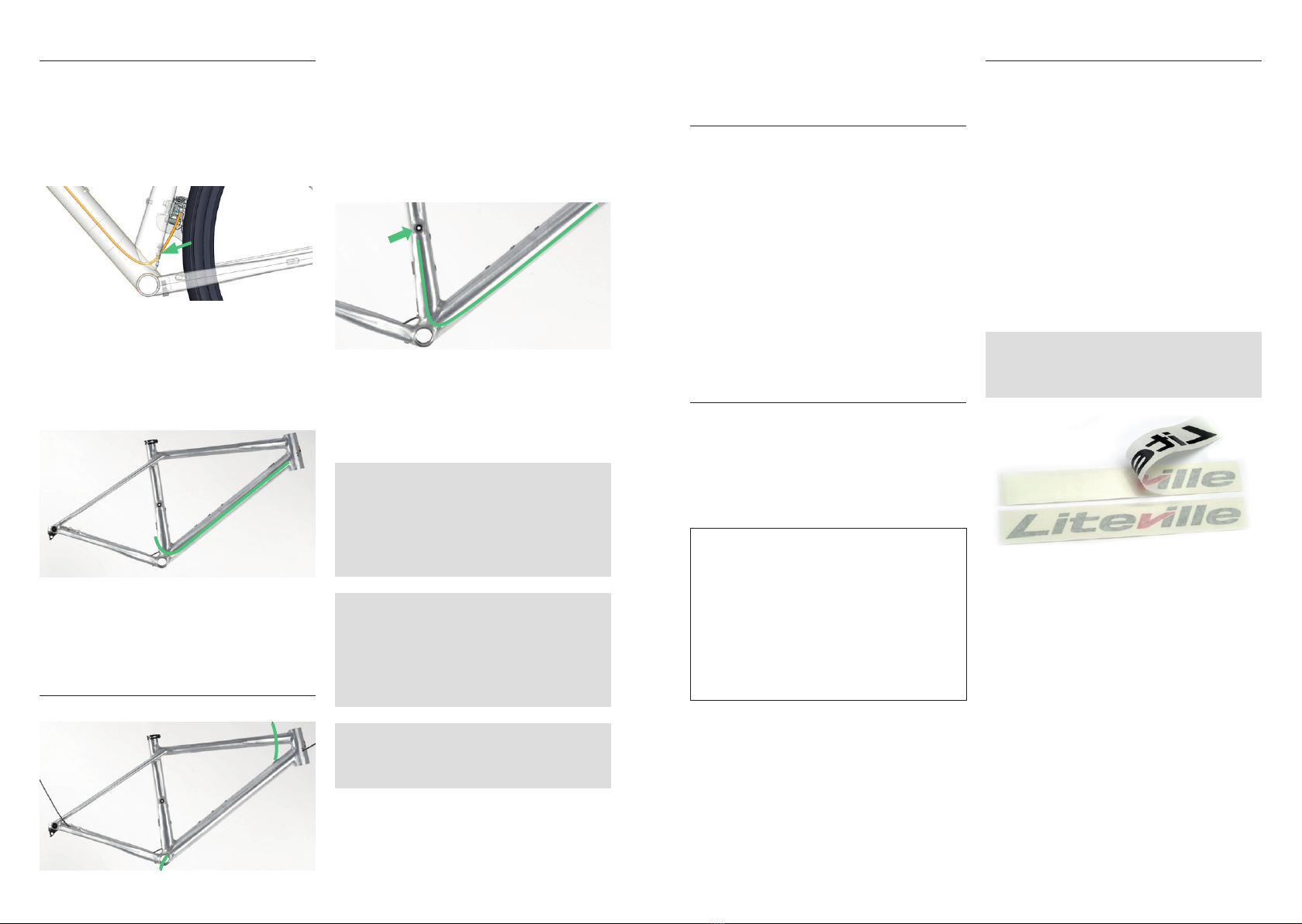

10.Cable routing front derailleur

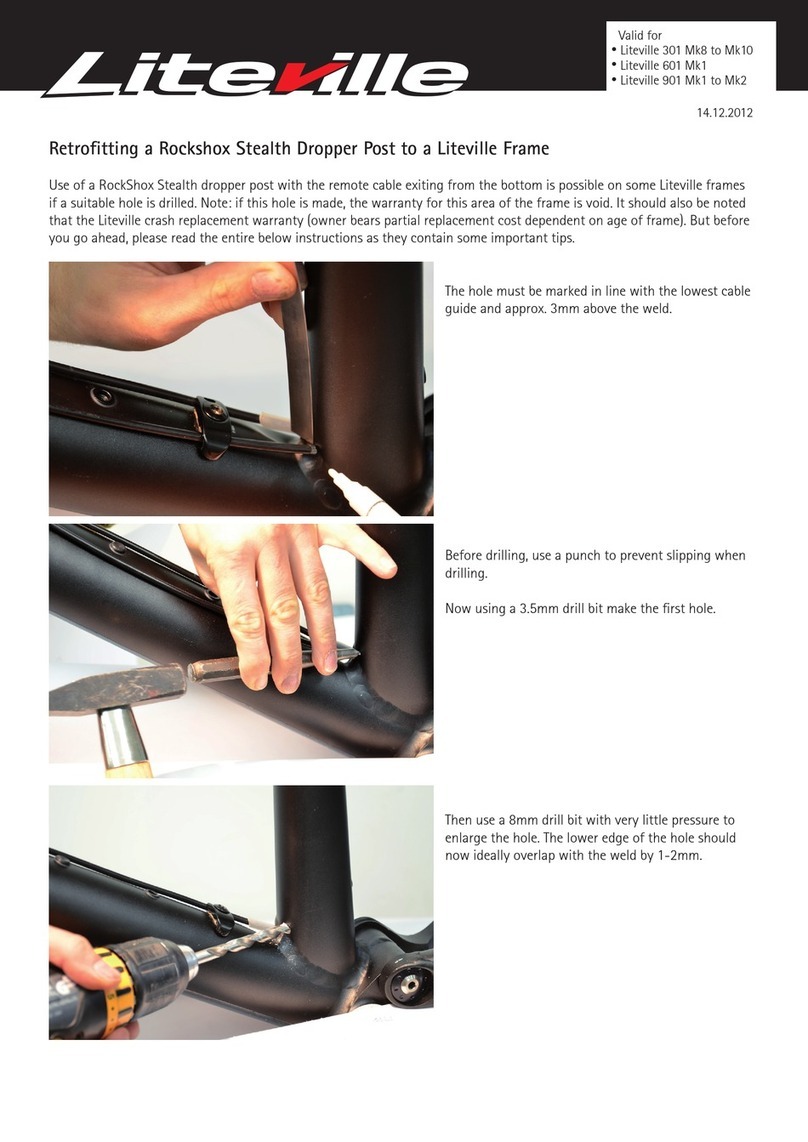

• Push the cable housing into the right-hand,

bottom hole at the steering tube. Guide the

housing through the down tube and have it exit

at the bottom bracket.

• From the bottom end, slip a foam tube over the

cable housing.

• Have the end of the cable housing exit at the

rear end of the seat tube.

• Install the black cable guidance and tighten

the screw at the frame cable exit hole.

• Cut the end of the cable housing with specific

Bowden cable pliers and connect it with the

front derailleur.

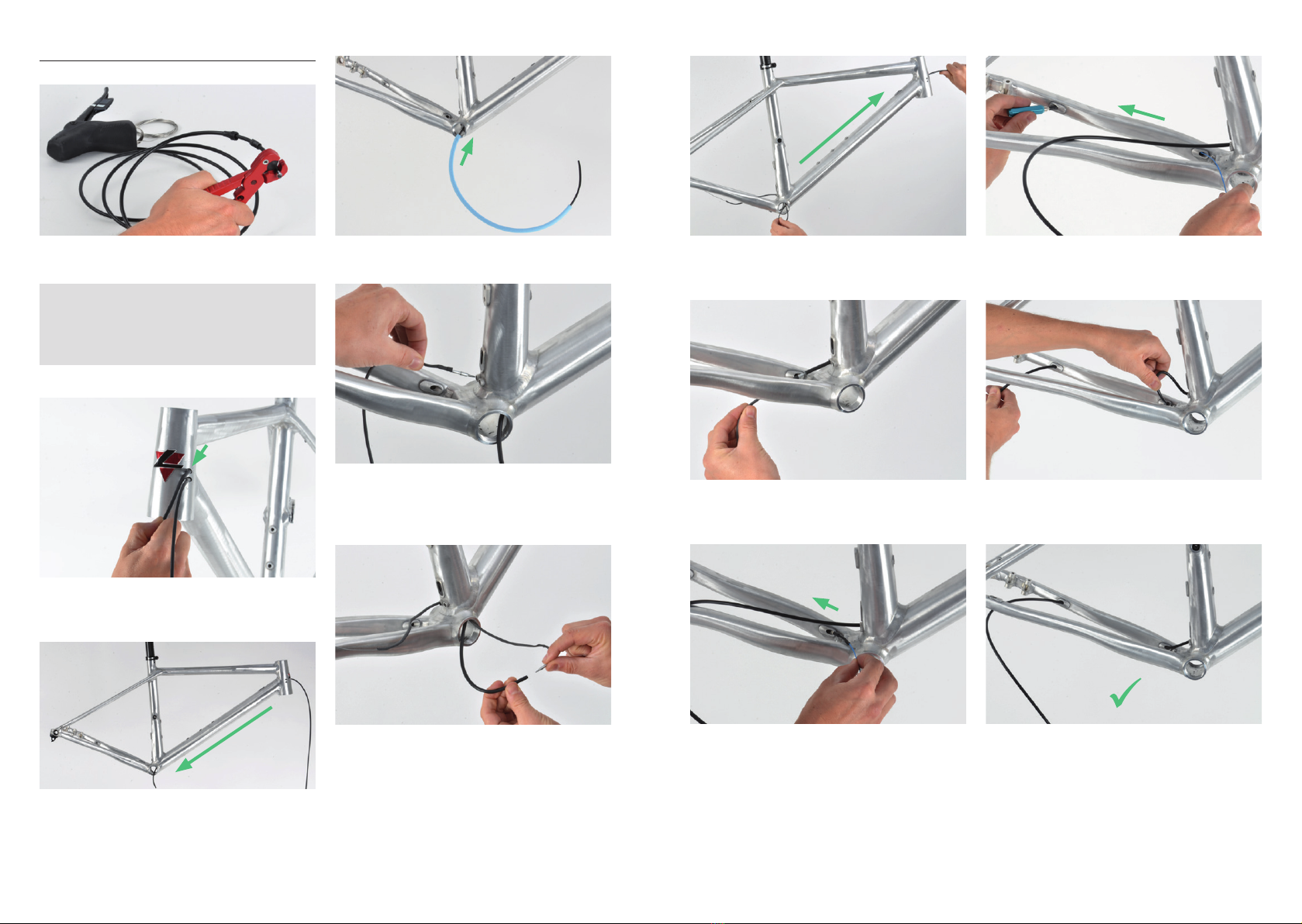

• Insert the cable housing or hydraulic hose into

the cable hole at the down tube, close to the

steering tube. Push the housing into the down

tube and have it exit at the right hand of the

bottom bracket.

• Now slip a foam tube over the bottom bracket

all the way to the top end of the housing, close

to the steering tube.

• From the bottom, push the housing into the

seat tube.

• For the assembly and installation of the vari-

able dropper post, stick to the manufacturers’

manuals.

NOTE: depending on the handlebar width,

the number of spacers underneath the stem,

the frame size and the length of the cable,

the cable housing or the hydraulic hose can

alternatively exit the frame at the right-hand

cable hole next to the steering tube.

NOTE: the seat tube is specifically

prepared for the installation of an Eightpins

variable dropper post with very precisely

manufactured, small tolerances. The

measurements of the frame including the

inner tube diameter must not be altered.

NOTE: in case the frame is painted or ano-

dized, the internal diameter of the seat tube

within the first 140 must not be altered.

E. MAINTENANCE AND CARE

1. Headset bearing

With normal usage, the bearings of the headset

do not have to be dismounted or greased.

In case you notice a defect bearing anyways, you

may order the specific bearing in your Liteville

WorksStation or directly at Syntace.

Never point at your bearings with a high-pres-

sure water jet as this can easily damage them.

After all, too much “maintenance” may even

harm your bearings.

2. Screws

The screws in your frame are all made from

Titanium or Aluminum and are produced

specifically for Liteville frames. They are all

mounted with screwlock. Nonetheless, you are to

check the correct tightening torque frequently.

ADVICE: in case a screw can actually be

twisted as the tightening torque is che-

cked, the screwlock is broken and as a

consequence needs to be exchanged. The

screw needs to be secured again. Unscrew

it, clean it and reassemble everything with

screwlock.

We have summed up a “Screwlock Basics”

at www.liteville.de > FAQ.

3. WorksFinish surface

The Liteville WorksFinish is a genuine raw Alu-

minum surface, free of any kind of protection

paint, meaning it is no Aluminum simulation. The

frame actually shows the signs of the original ma-

nufacturing process. Stains are thus common, the

frame may even change its color slightly which

leads to the natural charm of a grown patina.

The surface can be reprocessed at all times either

chemically or mechanically with a Scotch-Bri-

te-Finish or by being polished manually. The

frame comes standard with two Scotch-Brite

grinding fleeces. Try applying it on a spot that is

not seen directly.

NOTE: The WorksFinish frame comes with

3M stickers. It is your choice if you put them

on your frame or if you do not.

Picture shows Liteville stickers.