Contents

Introduction ................................................................................5

Specifications ..............................................................................5

Safety Considerations .....................................................................5

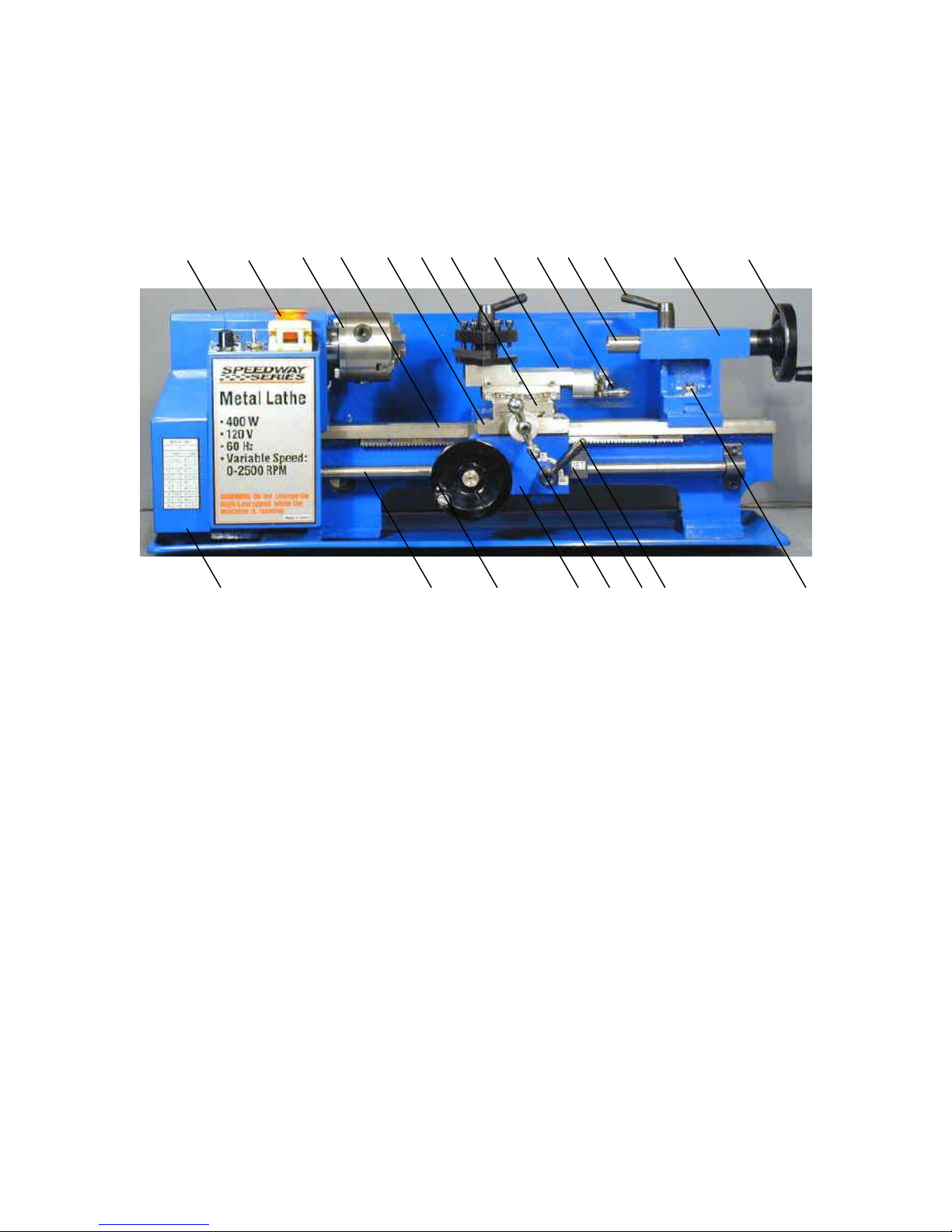

Features.....................................................................................6

Front View ...............................................................................6

Rear View ................................................................................7

Basic Accessories...........................................................................7

Cleaning .....................................................................................7

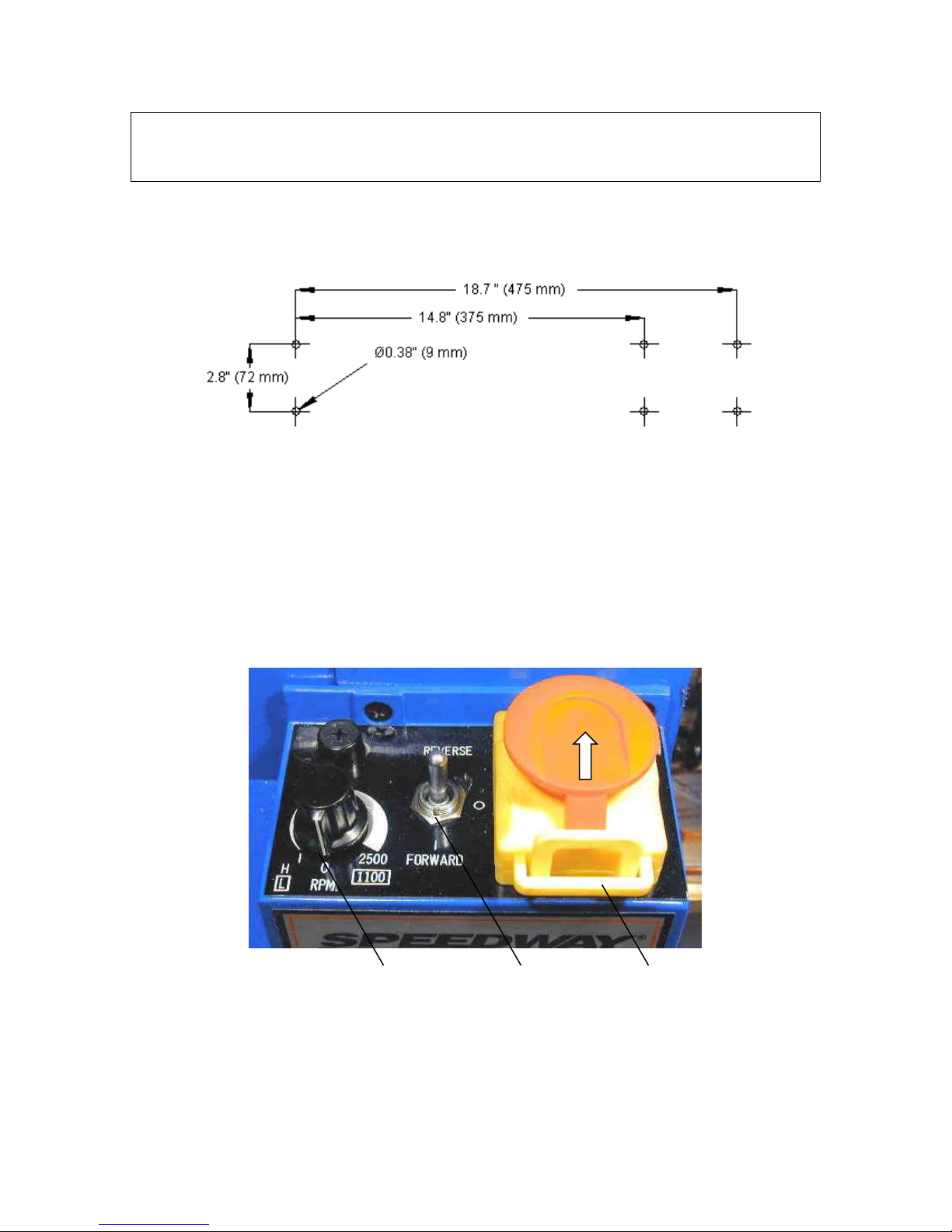

Mounting Your Lathe ......................................................................7

Operating Controls ........................................................................8

Motor Controls...........................................................................8

High/Low Speed Shifter ................................................................9

Power Feed Forward/Neutral/Reverse Lever ..................................... 10

Power Feed Lever ..................................................................... 10

Carriage Hand Wheel ................................................................. 10

Cross Slide Feed Handle.............................................................. 10

Compound Rest Feed Handle ........................................................ 11

Compound Rest Rotation............................................................. 11

Tailstock Lock Nut .................................................................... 11

Tailstock Quill Hand Wheel .......................................................... 11

Tailstock Quill Locking Lever........................................................ 11

Adjustments .............................................................................. 12

Carriage ................................................................................ 12

Cross Slide Gibs........................................................................ 12

Cross Slide Nut ........................................................................ 13

Compound Rest Gibs.................................................................. 13

Apron Position ......................................................................... 13

Half Nuts ............................................................................... 14

Lead Screw Mounting ................................................................. 14

Drive Belt............................................................................... 14

Lubrication................................................................................ 15

Lubricating the Transmission Gears ................................................ 17

Changing Chuck Jaws.................................................................... 17

Grinding Tool Bits........................................................................ 18

Grinding Tool Bits ..................................................................... 20

Grind the Front Relief ................................................................ 20