Contents

Introduction .......................................4

Specifications......................................4

Safety Considerations ............................5

General Safety .................................5

Lathe Safety ....................................5

Electrical Safety ...............................5

Machine Safety .................................6

Features ............................................7

Front View ......................................7

Accessories.........................................8

Cleaning ............................................8

Mounting Your Lathe .............................8

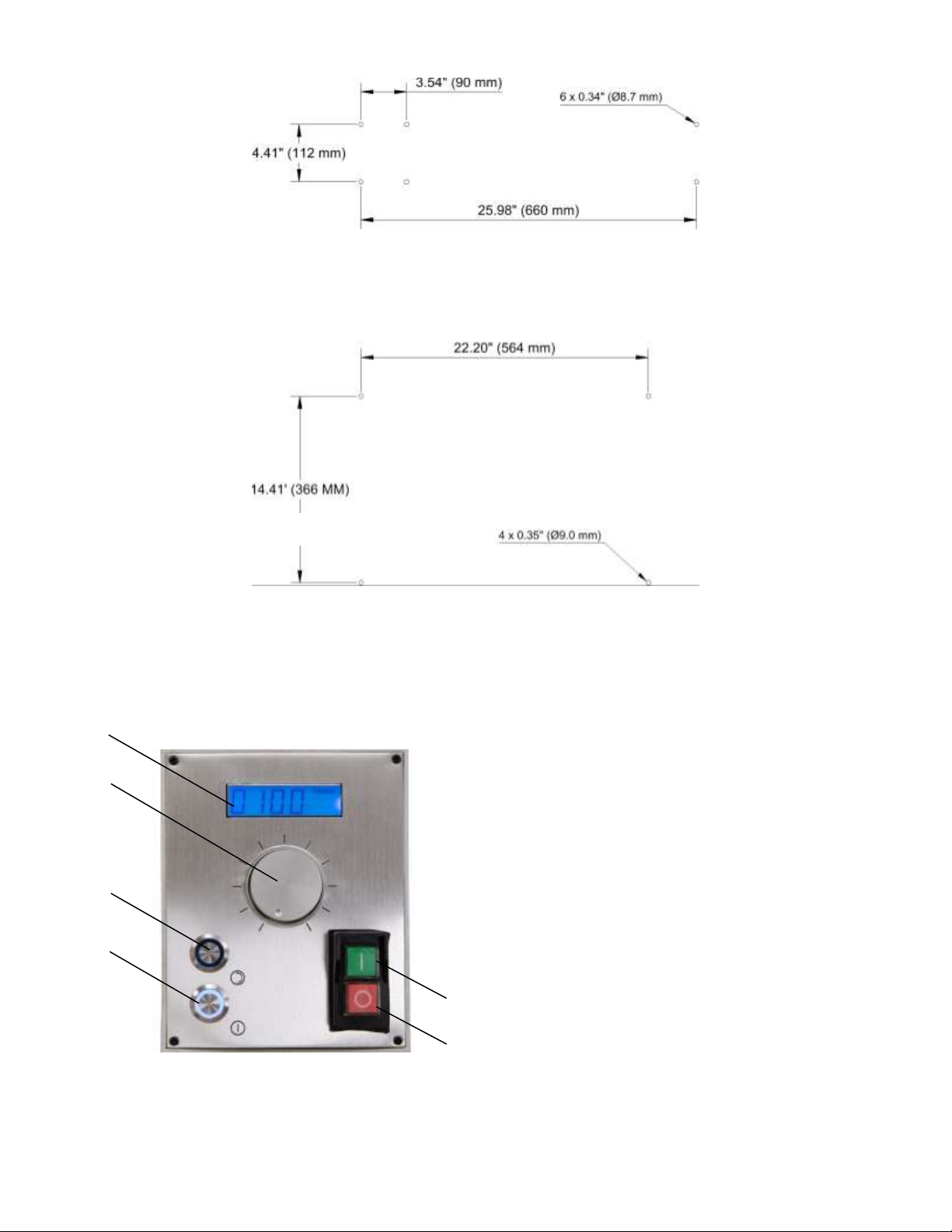

Lathe Controls.....................................9

Motor Controls..................................9

Carriage and Cross Feed Controls ......... 10

Tailstock Controls............................ 13

Bluetooth DRO (Model 7550 only) ............ 14

Using the app ................................. 15

Axis detail settings .......................... 15

Absolute versus incremental coordinates 16

Points and workspaces ...................... 16

Tools ........................................... 17

Adjustments ..................................... 17

Carriage ....................................... 17

Cross Slide Gib ............................... 18

Cross Slide Nut ............................... 19

Compound Rest Gib.......................... 19

Compound Rest Nut ......................... 19

Apron Position ................................ 19

Tailstock Position ............................ 20

Half Nuts ...................................... 21

Drive Belt ..................................... 21

Maintenance ..................................... 22

Cleaning ....................................... 22

Lubrication.................................... 22

Chuck ............................................. 23

Changing Chuck Jaws........................ 23

Mounting Work in a 3-Jaw Chuck.......... 24

Tool Bits.......................................... 24

Grinding Tool Bits............................ 25

Adjusting Tool Bit Height ................... 26

Turning ........................................... 27

Manual Turning............................... 27

Turning with Power Feed................... 27

Facing ............................................ 28

Facing with Power Feed .................... 28

Turning Angles .................................. 29

Threading ........................................ 29

Change Gears................................. 30

Change Gear Tables ......................... 32

Making Left Hand Threads.................. 33

Tool Bit ........................................ 33

Compound Angle ............................. 34

Setting the Cutting Tool .................... 34

Threading Process ........................... 35

Common Accessories ........................... 35

Quick Change Tool Post..................... 36

Indexable Turning Tools .................... 36

4-Jaw Chuck .................................. 37

Faceplate ..................................... 37

Live and Dead Centers ...................... 38

Steady Rest and Follower Rest ............ 38

Parts Diagram: 7500............................ 40

Parts Diagram: 7550............................ 42

Parts List ......................................... 44

Wiring Diagram.................................. 47