8

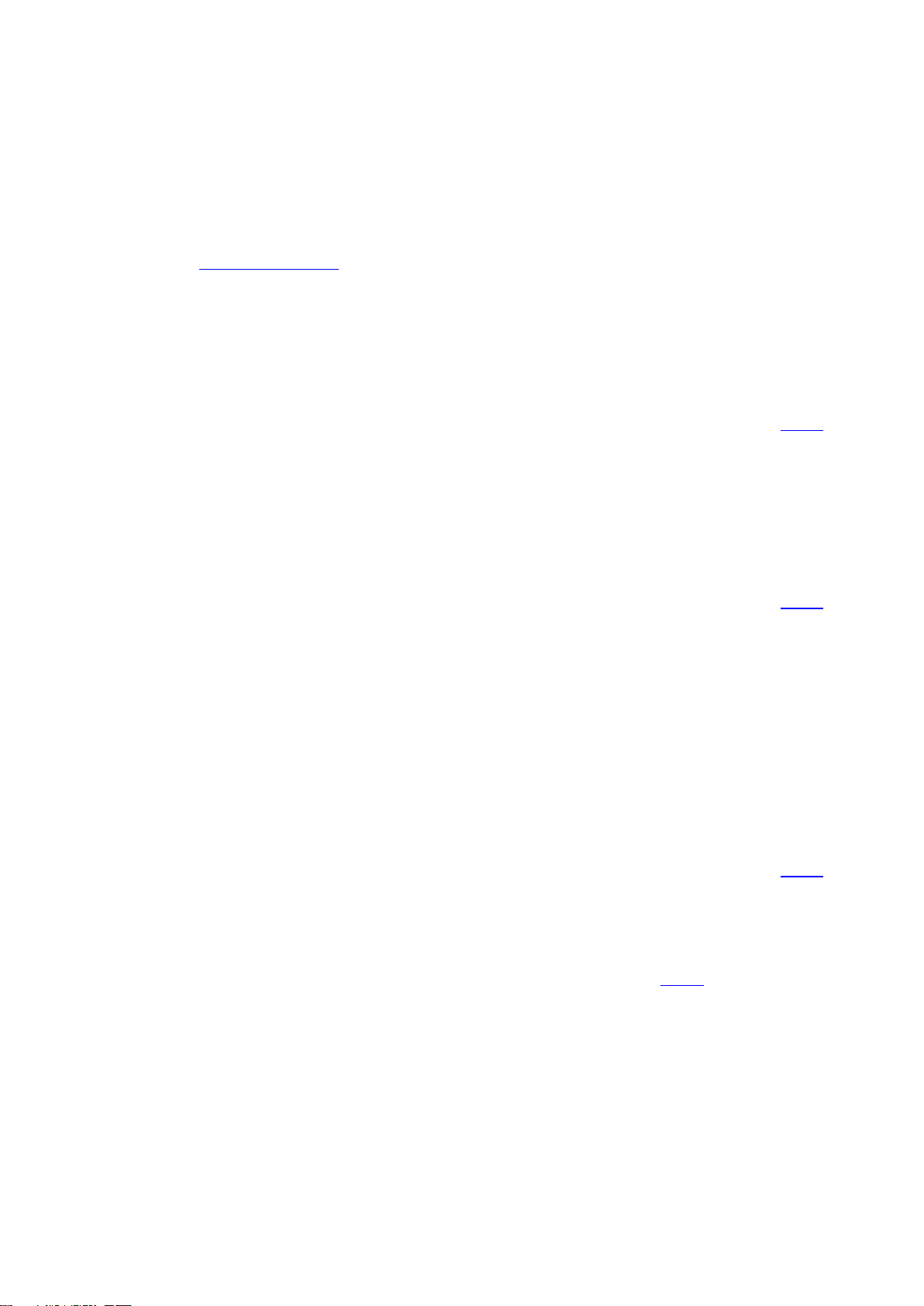

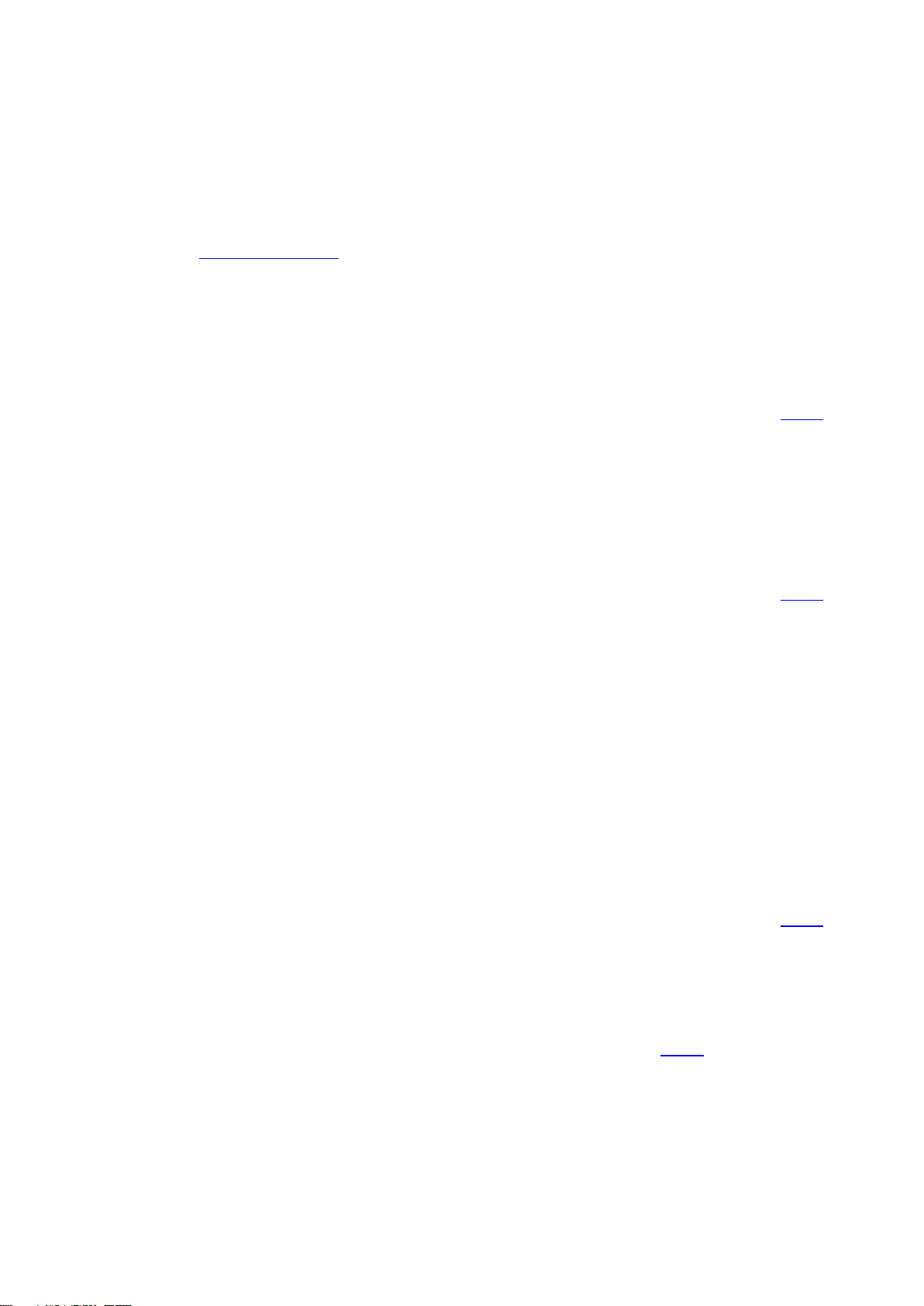

C. No tip vibration

1. Check that the tip is firmly tightened. Preferably use a torque wrench and tighten clockwise

until the torque wrench slides. (The torque wrench prevents the tip from being overtightened.)

2. Check that the green light below the keys on the control panel is lit. If it is not lit, please see

Section A on page 4.

3. Check that the device has been turned on by pressing the ON-key and that the blue light next

to the ON-key is lit.

4. Check that the Working Mode has been selected by pressing one of the Working Mode keys

and that one of the yellow lights on the control panel is lit.

5. If you have an additional handpiece, try replacing the handpiece.

6. If you have an additional foot control cable, try replacing the foot control cable.

7. If you have an additional foot control, try replacing the foot control.

8. If the problem still remains –contact your dealer for support and indicate Error Code E-S01

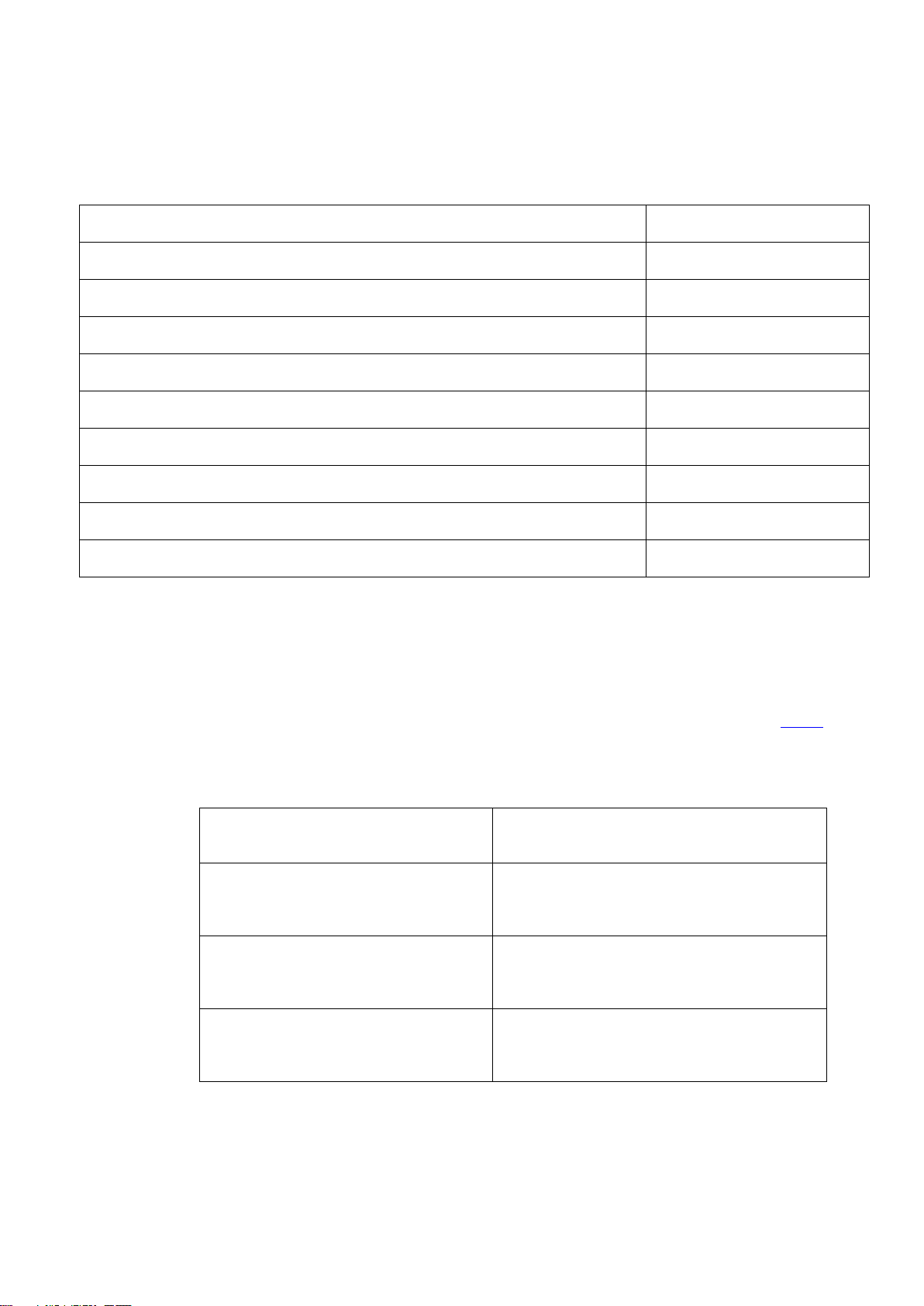

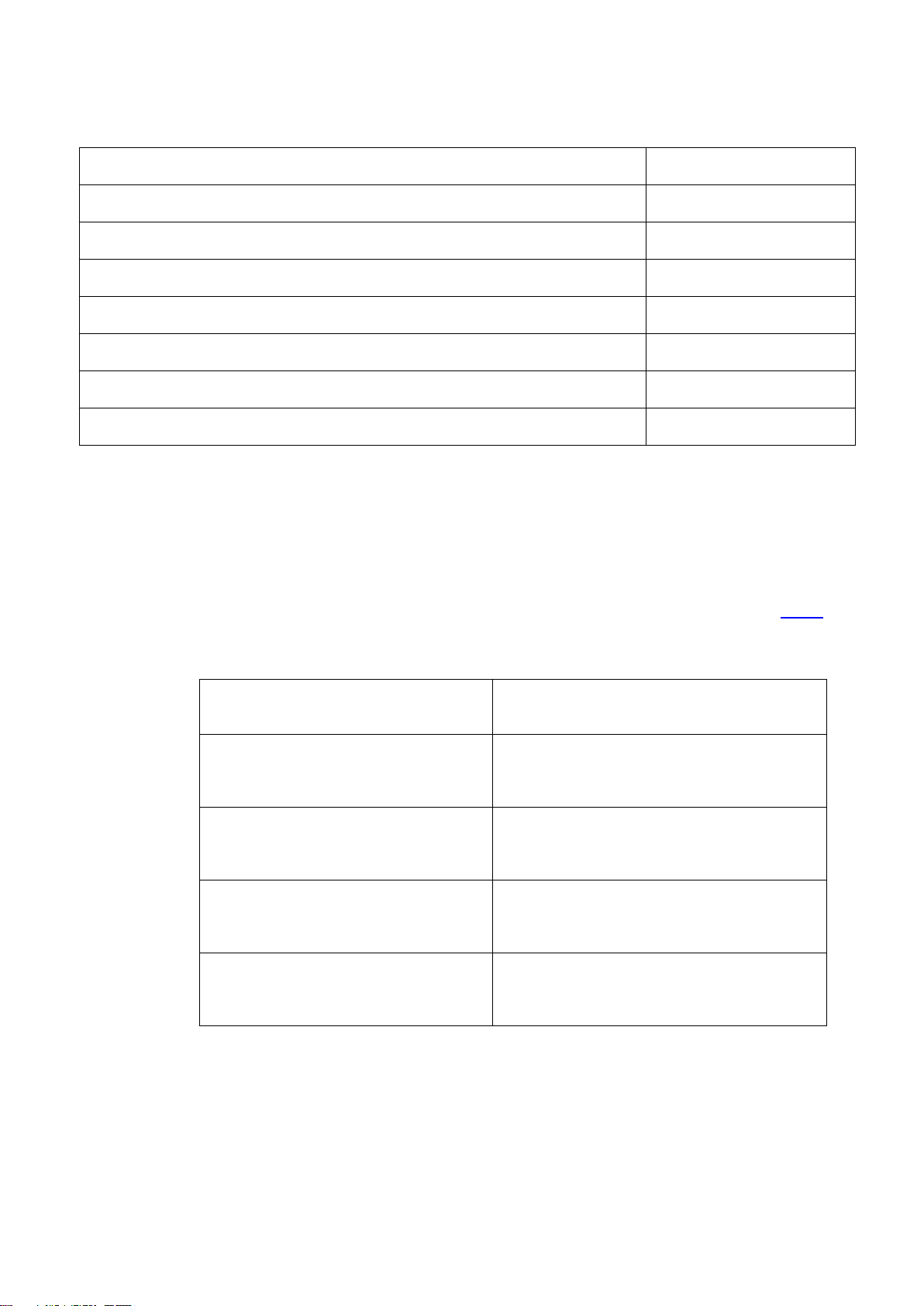

D. Weak tip vibration

5. Check that the tip is firmly tightened. Preferably use a torque wrench and tighten clockwise

until the torque wrench slides. (The torque wrench prevents the tip from being overtightened.)

6. Check that the tip is not worn out. Use a tip check card to evaluate wearing or try an unused

tip. Use original LM-Instruments tips for reliable performance.

7. If you have an additional handpiece, try replacing the handpiece.

8. If the problem still remains –contact your dealer for support and indicate Error Code E-S02

E. Insufficient or no water flow when foot switch is activated

1. Check that the medicament/water bottle is properly connected i.e. the cap is tightened and

pushed in all the way onto the connector. Check that the o-rings on cap and connector are in

good condition. Replace o-rings if worn. O-rings can be lubricated with a glycerine based

lubricant (or vaseline).

2. Check that dry mode is not activated i.e. that the blue light next to the crossed-out water drop

is not lit. If it is lit, press the ON-key.

3. Adjust the water control ring on the handpiece to fully open (dots aligned).

4. Try with another tip.

5. Use the LM-ProPower Fixer to check that the water hose inside the handpiece has not stuck

in the autoclave. Insert the Fixer carefully into the handpiece from the hose connector side.

(To avoid the hose getting stuck, the water adjustment on the handpiece should be set to fully

open before sterilization in autoclave.)

6. If the problem still remains –contact your dealer for support and indicate Error Code E-S04

F. Tip does not fit smoothly onto the handpiece

1. Clean handpiece threads with compressed air and try with a new tip

2. If the problem still remains, the threads of the handpiece may be damaged and the handpiece

needs to be replaced. Contact your dealer and indicate Error Code E-S06.