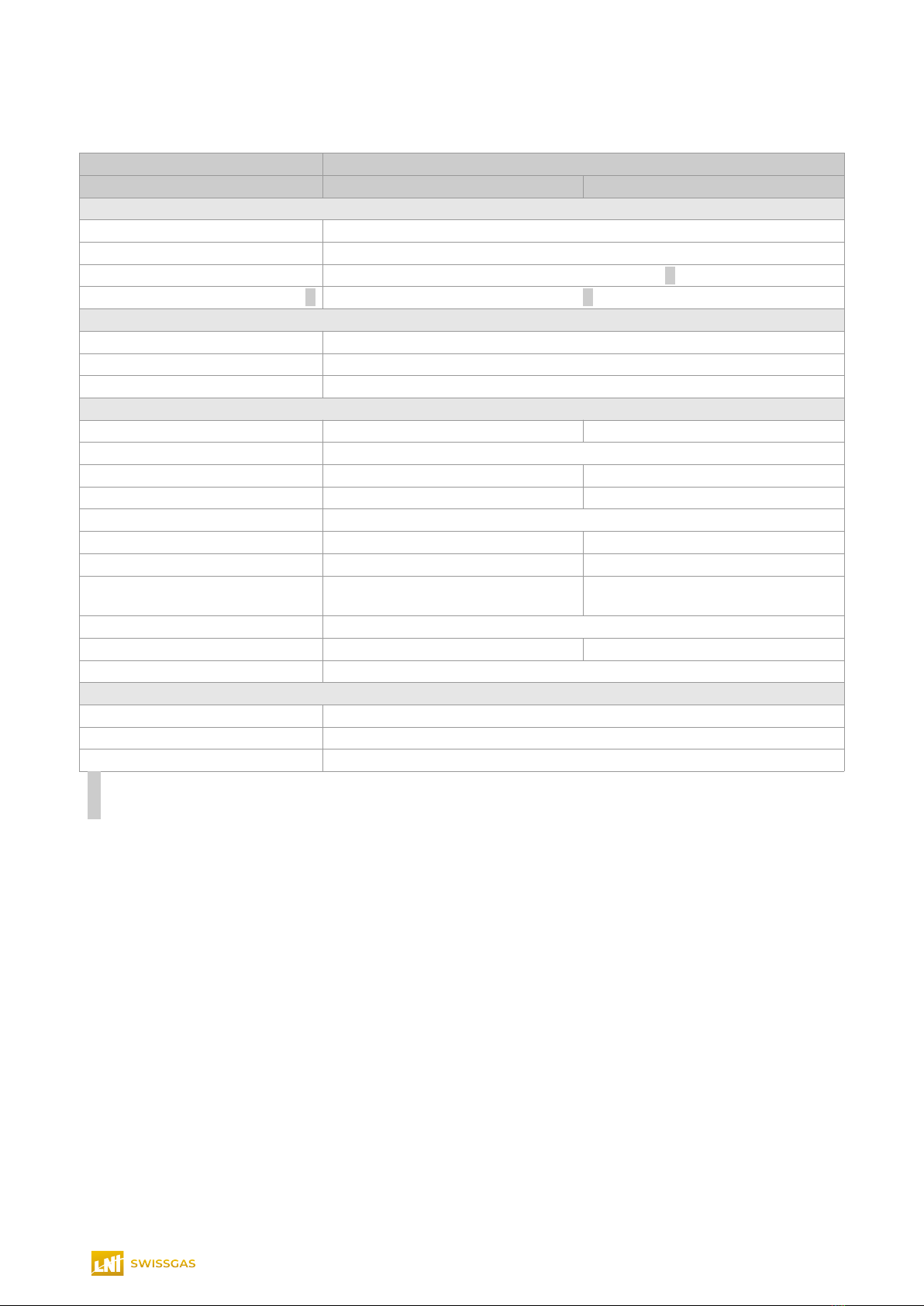

Table of contents

1 General informations................................................................................................................1

1.1 Symbols and terminology................................................................................................................1

1.2 General warnings............................................................................................................................2

1.3 Safety information...........................................................................................................................2

1.4 Intended use....................................................................................................................................3

1.5 Improper use...................................................................................................................................3

1.6 Reference directives........................................................................................................................3

1.7 Disposal...........................................................................................................................................3

2 Description of t e appliance.....................................................................................................4

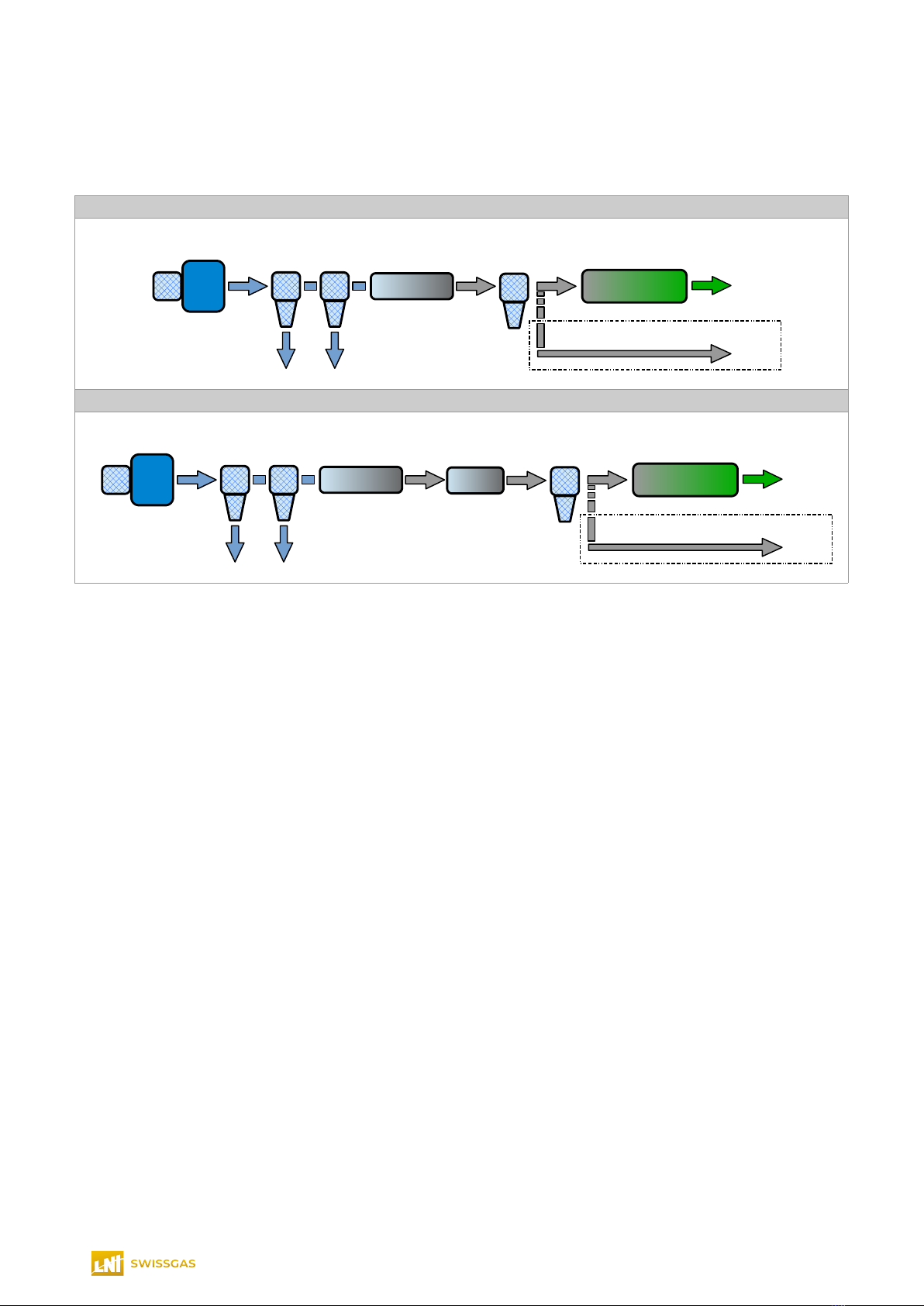

2.1 Operating principle..........................................................................................................................4

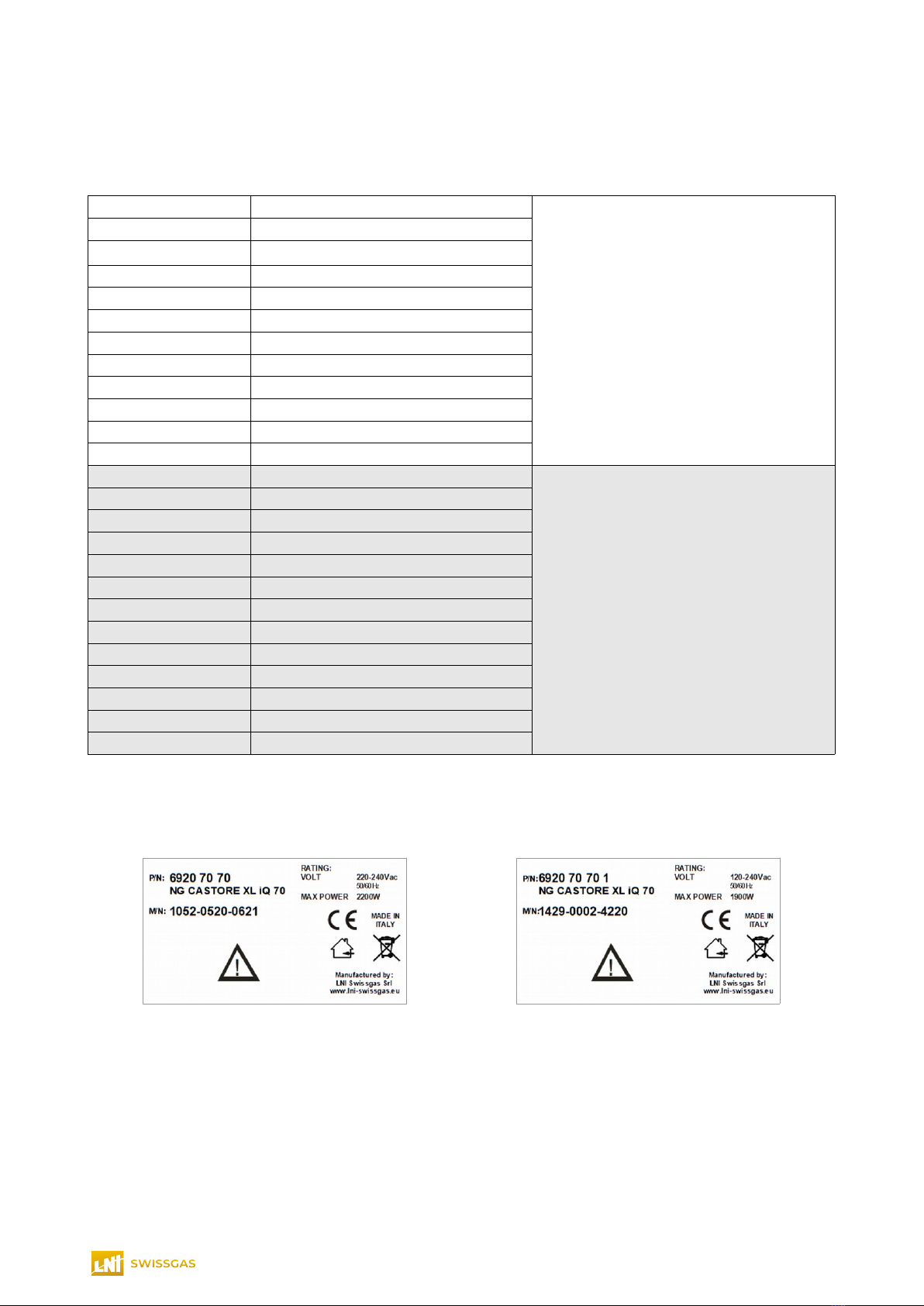

2.2 Identification of the models..............................................................................................................5

2.3 Technical specifications...................................................................................................................6

2.3.1 Operating and storage conditions...............................................................................................................6

2.3.2 NG CASTORE XL iQ 20..............................................................................................................................6

2.3.3 NG CASTORE XL iQ 40..............................................................................................................................7

2.3.4 NG CASTORE XL iQ 50..............................................................................................................................8

2.3.5 NG CASTORE XL iQ 70..............................................................................................................................9

2.3.6 NGA CASTORE XL iQ 20.40.....................................................................................................................10

2.3.7 NGA CASTORE XL iQ 40.40.....................................................................................................................11

2.3.8 NGA CASTORE XL iQ 20.60.....................................................................................................................12

2.3.9 NGA CASTORE XL iQ EVOQ...................................................................................................................13

2.3.10 NGA CASTORE XL iQ MP AES..............................................................................................................14

2.3.11 NGA CASTORE XL iQ QSight SS...........................................................................................................15

2.3.12 NGA CASTORE XL iQ QSight DS..........................................................................................................16

2.3.13 NGA CASTORE XL iQ SCIEX.................................................................................................................17

2.3.14 NGA CASTORE XL iQ SCIEX 7500........................................................................................................18

2.4 Weight and dimensions.................................................................................................................19

2.4.1 Weight........................................................................................................................................................19

2.4.2 Dimensions................................................................................................................................................19

2.5 Overview of the appliance.............................................................................................................20

3 Receiving t e appliance..........................................................................................................21

3.1 Packing list....................................................................................................................................21

4 Available accessories (not included, to be requested separately)......................................22

4.1 Purge tank – 6950.92.062.............................................................................................................22

4.2 Pressure regulators box................................................................................................................22

5 Installation............................................................................................................................... 24

5.1 Installation layout...........................................................................................................................24

5.2 Positioning.....................................................................................................................................25

5.3 Pneumatic connections.................................................................................................................26

5.4 Electrical connection.....................................................................................................................27

6 Commissioning....................................................................................................................... 28

6.1 Starting the appliance the first time...............................................................................................28

6.2 Shutting down................................................................................................................................29

6.3 Returning the appliance for service and/or repairs.......................................................................29

7 Operation................................................................................................................................. 30

7.1 User interface................................................................................................................................30

7.2 Summary screen...........................................................................................................................31

7.2.1 System status............................................................................................................................................32

7.3 Starting and stopping nitrogen production....................................................................................32

7.4 Serial communication and connections.........................................................................................33

7.4.1 Digital I/Os.................................................................................................................................................33

7.4.2 Auxiliary connections.................................................................................................................................33

7.5 Parallel Mode.................................................................................................................................34

7.5.1 Introduction................................................................................................................................................34

7.5.2 Kit Parallel system control box with LAN kit (P/N: 6920.71.60)...............................................................34

7.5.3 Electrical connection..................................................................................................................................35

7.5.4 Installation with multiple generators..........................................................................................................35

7.5.5 System ID setting......................................................................................................................................36

7.5.6 System status............................................................................................................................................36