HELI gieen Series Installation and operating instructions

FOREWORD

The G series 1.6-1.8t electric narrow aisle reach truck is new offering of HELI to

meet market needs. The new series is designed on the base of the advantages of some

reach trucks made by domestic and foreign manufacturers. It has modern designed

appearance, simple structure, comfortable operation, and superior maneuvering

performance. It is mainly used for goods handling and stacking indoor with narrow

aisle such as factory, warehouse, supermarket and so on.

The series truck has streamline appearance and ergonomic designed cab; AC

type lifting, travelling and steering control systems are applied on the truck; three

phase AC type motors are assembled on the truck; the operator has wide view with

three stage full free high lifting mast; EPS electric powered steering system makes

steering easy; electromagnetic brake of the front wheel and energy regenerating

technology of AC motors effectively reduce noise and improve truck comfort and

reliability; the truck has precise and stable operation through superior motor, battery,

multi function LCD meter and DC-DC pressure converter; buffers at the upper and

lower limit position and during mast lifting and lowering effectively reduce working

noise and realize stable moving; with CAN bus technology, the truck is more reliable;

lifting height display and pre-selector are optional. The truck has the characteristics of

good performance, easy operation, flexible steering, reliable brake, good power, low

noise and no pollution and so on.

This manual states the trucks’ specification, operation, maintenance, service, main

assemblies’ constructions and working principles so as to help operators to use the

truck correctly and attain the highest function. It is necessary to read over the manual

before operating the trucks.

The rules and notices in the manual should be abided seriously by all of the

relative people to enable these trucks in optimized working state for long period and

bring the highest efficiency.

The graphic illustrations such as pictures, drawings and parts characters and so on

in the manual are not in real proportion because of the limit of space, so you can not

get the size and weight accurately from the graphic illustrations which are to describe

the correct operation methods of the devices and parts.

This manual might not correspond with the actual condition because of the

improving of our products. Our products are subject to improvements and changes

without notice.

CONTENTS

I. Safety Instructions of Operation and Driving……………………………………..1

II. External View of Reach Truck……………………………………………………5

III. Main Specifications………………………………………………………………6

IV. Construction and Principle of Reach Truck………………………………………7

4.1 Transmission system………………………………………………………..7

4.2 Rear axle………………………..……………………………………………9

4.3 Steering system……………………….……………………...…………11

4.4 Supporting wheel assembly…………….……………………………..12

4.5 Brake system ……………….…………………………………………14

4.6 Hydraulic system……………….……………………………………...….17

4.7 Body system……………..……………………………………………….29

4.8 Lifting system……………………………………………………….……31

4.9 Electric system………………………………………...……………………53

V. Troubleshooting…………………………………………………………………..93

5.1 Transmission system………………………………………………………93

5.2 Steering system…………………………………………………………….93

5.3 Parking brake system………………………………………………………93

5.4 Hydraulic system…………………………………………………………..94

5.5 Electric system……………………………………………………………95

VI. Maintenance……………………………………………………………………96

VII. Others………………………………………………………………………….99

7.1 The size and weight of the main takedown parts of the truck……………..99

7.2 Mast disassembly…………………………………………………………. 99

7.3 Overhead guard disassembly………………………………………………99

7.4 Vibration specification…………………………………………………...100

1

I. Safety Instructions of Operation and Driving

1. Drivers and equipment keepers should keep “safety first” in mind and operate

according to the operation and service manual.

2. Transporting

Pay attention to the following instructions before transporting the forklift with

containers or trucks:

2.1 Take the working device backward, turn off the battery and pull the parking

brake;

2.2 Hang up the forklift according to the decal. It is not allowed to hang the mast

or get into or out the truck directly by platform.

2.3 Fix the overhead guard and mast with wire and wedge wheels securely when

delivering the forklift.

3. Storage

3.1 Lower the forks to the floor;

3.2 Turn off the key switch and emergency switch, place all operating levers in

neutral and pull out the plug from the battery set.

3.3 Pull the parking brake;

3.4 Put up the wheels and recharge the battery once every month when the

forklift is lying by for a long time.

4. Preparations for start

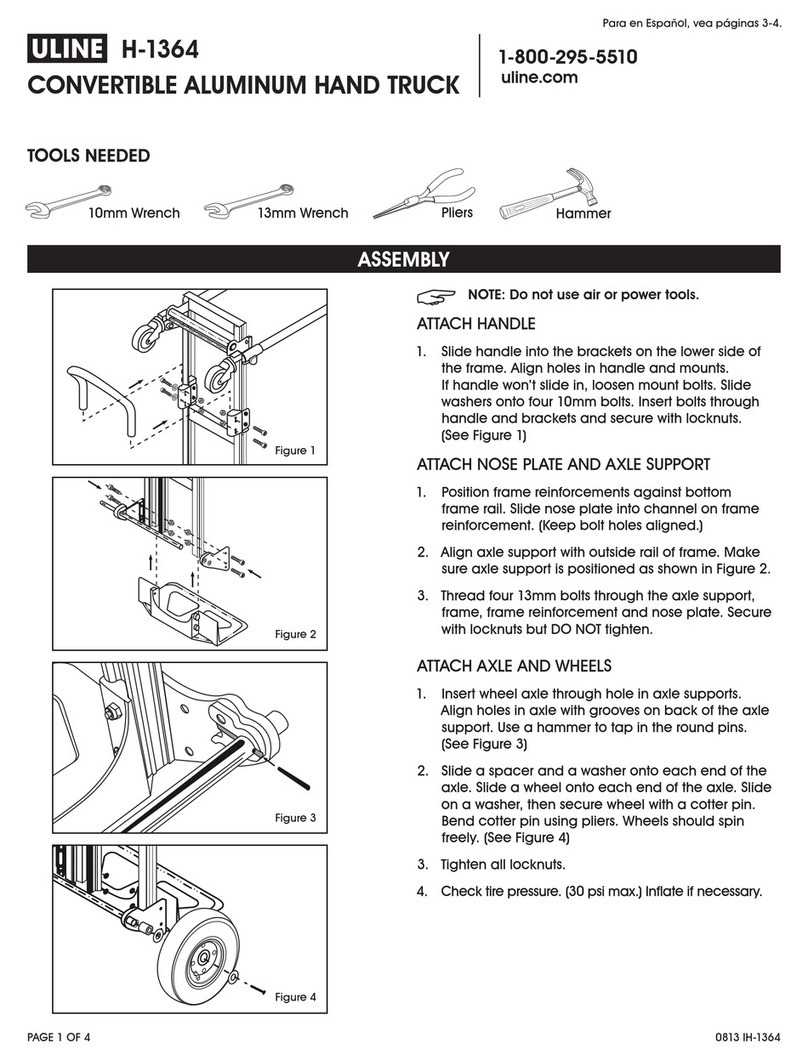

4.1 Read the manual carefully to get familiar with the meters, operating levers,

construction and functions of the forklift before driving. Please see figure 1. The

drivers must have license.

2

Figure 1-1 Layout of instrument and operating mechanism of standard model

1. Brake pedal (pedal safety switch) 2. Steering wheel 3. Key switch

4. Display instrument 5.6.Automatic centering switch 7. Front lamp

8. Integrated knob 9. Emergency button

4.2 Check all the instruments for normal function;

4.3 Check the polyurethane solid tyre;

4.4 Check all operating switches and pedals;

4.5 Check the battery for output voltage, specific gravity and state of battery

capacity;

4.6 Check all of the connectors and plugs in the electric system for reliable

contact and accelerator pedal for effectiveness and flexibility;

4.7 Check hydraulic oil, electrolyte and brake fluid for leakage;

4.8 Check main fixing parts for tightness;

4.9 Make the trial of the mast for lifting, lowering, forward and backward tilting

and the truck for steering and braking.

3

5 Precaution in driving

5.1 Do not grasp the steering wheel when getting on the truck.

5.2 Pay attention to the state of mechanical, electrical, hydraulic system and

MOSFET speed adjuster.

5.3 Turn on the key switch and pull up the emergency switch, then push forward

or pull backward integrated knob to keep proper acceleration.

5.4 Read the electric energy on the meter and charge the battery or change a full

one when the capacity of the battery is less than one LED.

5.5 Do not over load. Insert the forks to pallet correctly and do not hand

off-center loads.

5.6 Starting, steering, driving, braking and stopping should go well. Slow down

when steering.

5.7 Do not stand under the fork and on the fork when lifting the fork.

5.8 Do not operate the levers or attachment out of the seat. Do not stand on the

telescopic working device in case of danger of mis-operating the telescopic levers.

5.9 Tilt the mast forward or backward completely or ensure the operating levers

back to neutral position when the mast is at the highest position.

5.10 When releasing operating levers suddenly during mast lowering, the mast

will act after a short time.

5.11 When travelling with load, tilt the mast backward, retract the working

device and keep the load as low as possible. Do not travel or steer when lifting the

mast.

5.12 When driving, be careful of the passersby, obstacles and rough road, and

make sure there is enough clearance between the mast and the entrance.

5.13 Do not brake suddenly.

5.14 Before leaving the forklift truck, lower the fork fully, place levers in neutral,

turn off the battery and pull the hand brake.

4

5.15 Do not adjust the pressure of the control valve and safety valve which has

been adjusted well in our company as will.

5.16 Check the chain regularly.

5.17 According to the measurement method specified in JB/T3300, the maximize

noise at the outboard of the truck should be no more than 75dB (A).

6. Charging

6.1 Obey the stipulations strictly in operation instruction for battery when first

charging or recharging.

6.2 if the output voltage of the battery is reduced to 41V /31V, or the voltage of

anyone lower than 1.7V or the meter alarms, the truck should stop working

immediately until the battery is replaced or charged.

6.3 When charging, often check specific gravity, liquid leveL and temperature of

the electrolyte.

6.4 Charge the battery as soon as possible (in 24 hours) after working. Do not

undercharge or overcharge in case of a damage to the battery.

6.5 Please refer to the battery operation and service manual for charging method

and maintenance.

5

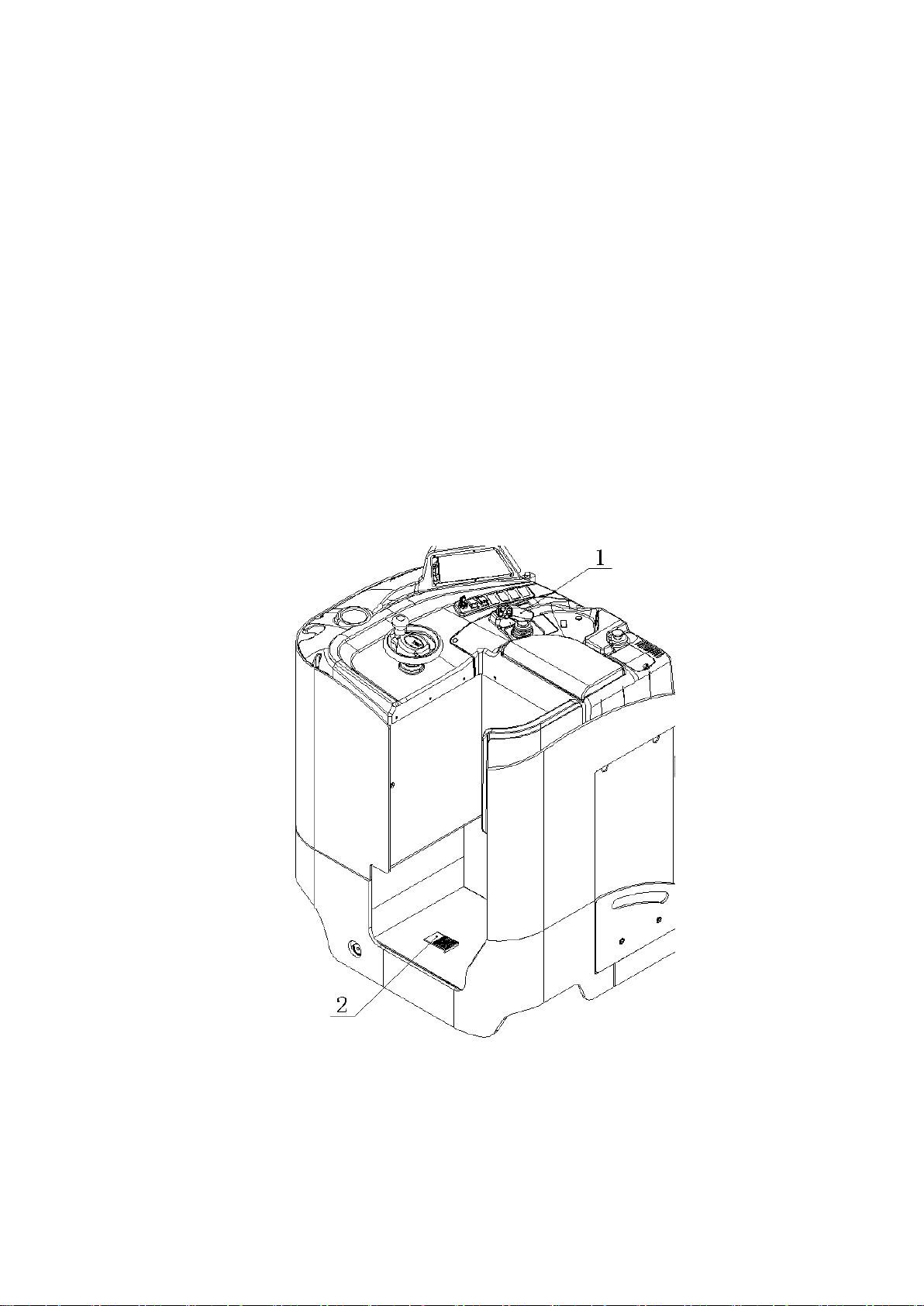

II. External View of Reach Truck

Figure 2-1 External view of reach truck

6

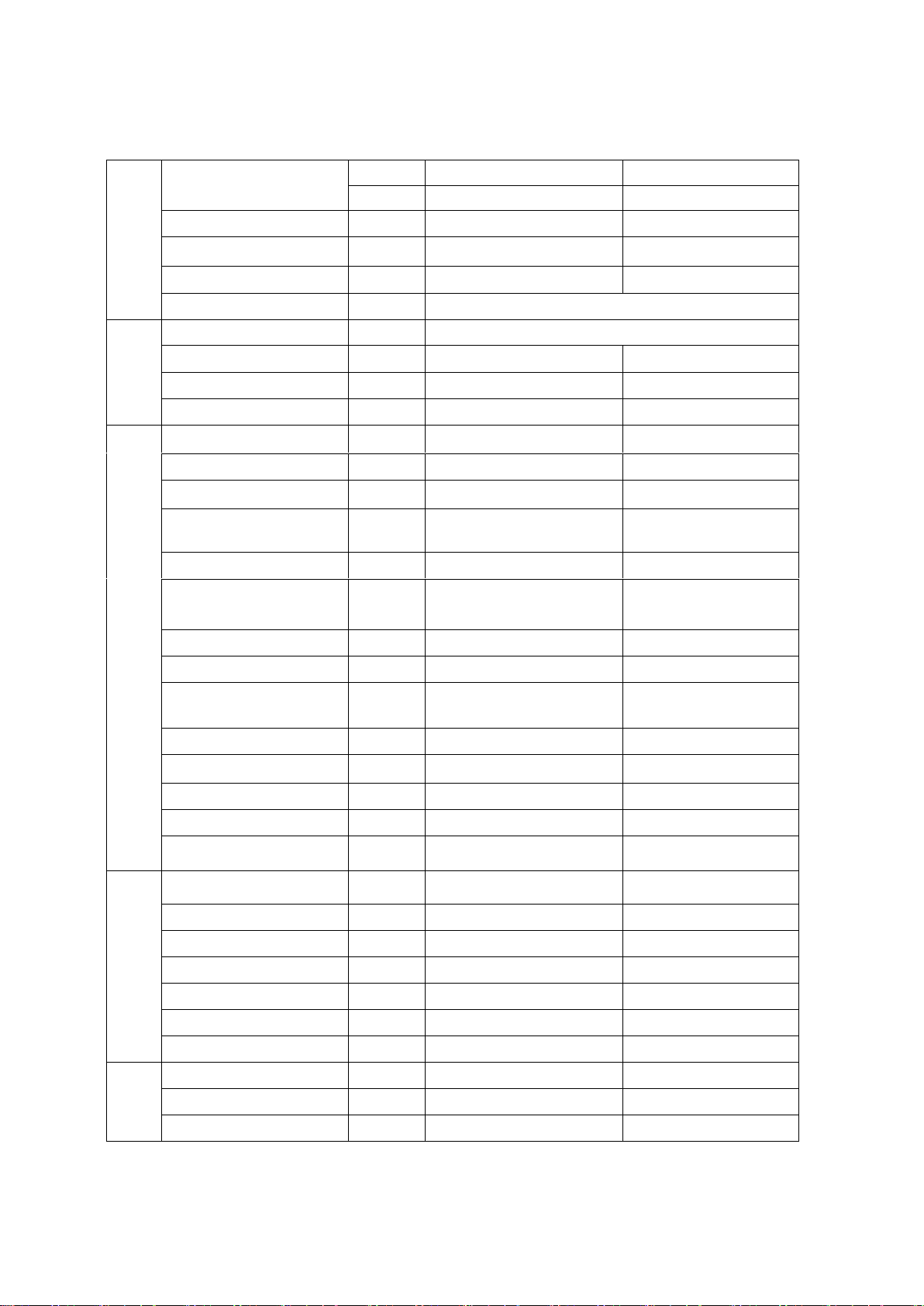

III. Main Specifications

Characteristic

Model

CQD16X1

CQD18X1

GB2R

GB2R

Driving type

Stand-on type

Stand-on type

Battery voltage/capacity

V/Ah

36/775,48/500

36/930,48/560

Battery weight

kg

800

940

Parking brake

Electromagnetic brake

电磁制动

Wheels

Tyre type

Polyurethane

聚氨酯

Load wheel

mm

Ф127x99

Ф127x99

Drive wheel

mm

Ф330x140

Ф330x140

Auxiliary wheel

mm

Ф178x76

Ф178x76

Dimensions

Standard lifting height

mm

5330

5330

Mast height, lowered

mm

2526

2526

Tilting angle(Fwd/Bwd )

º

3/4

3/4

Fork length/width/thickness

mm

920x100x35

920x100x35

fork side shift amount

mm

±50

±50

Truck length

(without fork)

mm

1815

1865

Truck width

mm

1090

1090

Overhead height

mm

2320

2320

Min.underground

clearance (at mast)

mm

60

60

Front overhang

mm

318

318

Reaching forward distance

mm

600

600

Wheel base

mm

1407

1457

Min. steering radius

mm

1695

1745

Right angle stacking width

mm

2817

2832

Performance

Travelling speed, w/o load

km/h

11.8/10.5

11.8/10.5

Lifting speed, w/o load

m/s

0.51/0.33

0.51/0.33

Lowering speed, w/o load

m/s

0.5/0.5

0.5/0.5

Front reaching speed, w/o load

m/s

0.15/0.11

0.15/0.11

Rated capacity

kg

1600

1750

Load center

mm

600

500

Max. gradeability, w/o load

%

15/10

15/10

Motors

Driving motor power

kw

7

7

lifting motor power

kw

15

15

Steering motor power

kw

0.6

0.6

7

IV. Construction and Principle of Reach Truck

4.1 Transmission system

4.1.1 Working principle

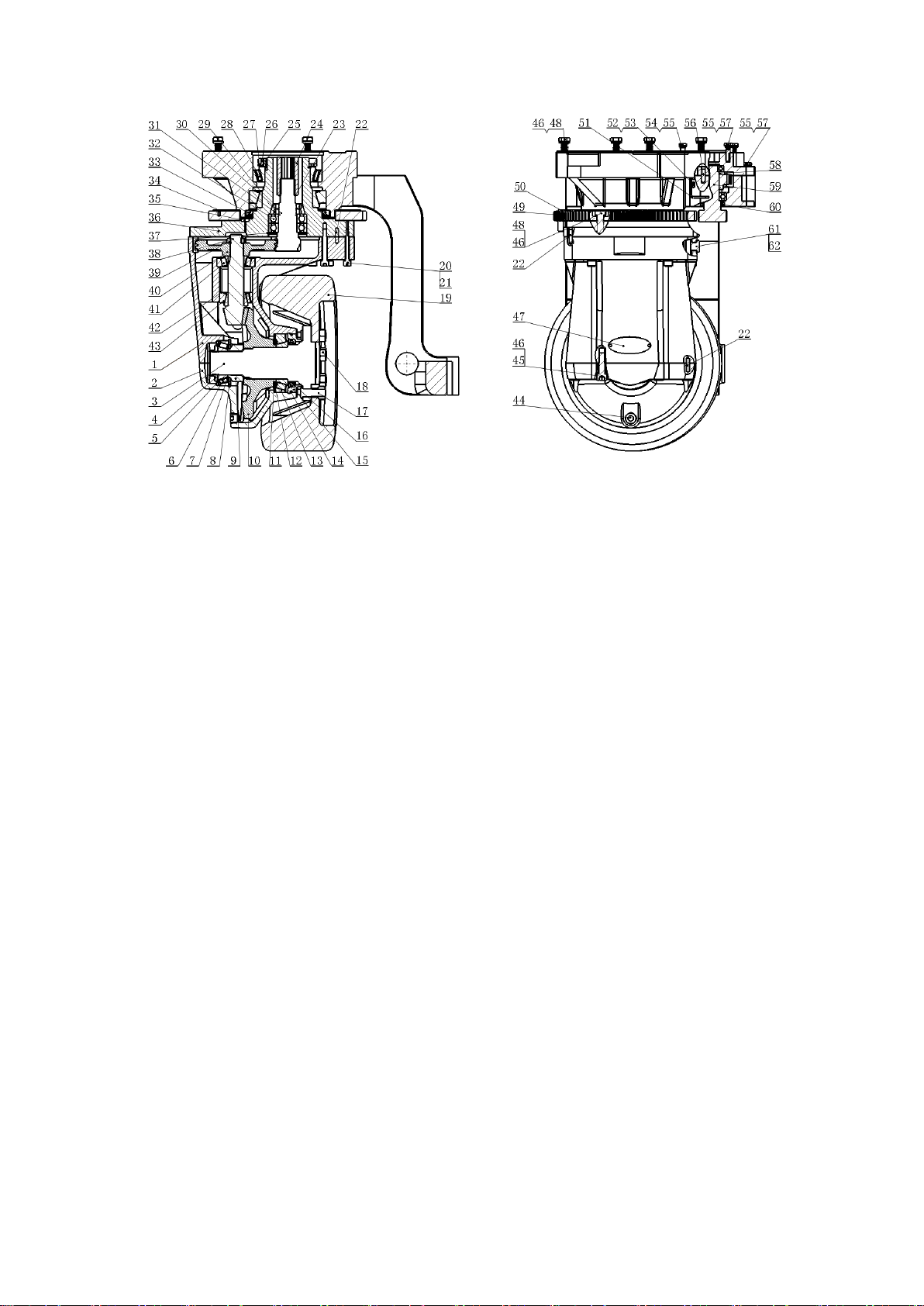

The drive unit of the truck is compact and reasonable arranged. Please see table 1

for its main performance parameters and figure 4-1-1 for structure. The working

principle is that the output shaft of the motor is connected with drive gear through

spline housing, positioned through spline and fixed through retainer ring. First level

deceleration is achieved through gear mesh transmission of the drive gear and driven

gear and the second level deceleration is achieved through gear mesh transmission of

the input shaft and spiral bevel tooth. The power is transmitted to output shaft after a

90°changing of transmitting direction and thus the drive wheel rotates. The steering

mode of the whole drive unit is of electric steering. That is a meshed gear pair is

driven by steering motor. The steering mode is simple and easy.

Table 1

Item

Parameters

Transmission box type

Stepless

transmission

Speed ratio of forward gear

22.6

Speed ratio of reversing gear

22.6

Drive wheel specification

(diameter×width))

φ330×1 40

Oil type

80W/90GL-5

Oil adding quantity

About 3.6L

Total weight (motor and drive

wheel not included)

178Kg

8

Figure 4-1-1 Drive unit

1. Support of transmission box

case

2. Transmission box case cover

3. Drive axle

4. lock nut

5. oil retainer

6. bearing 30209

7. washer

8. retainer ring

9. spacer

10.spiral bevel gear

11. washer

12. retainer ring

13. bearing 30212

14. O ring

15. oil seal holder

16. oil seal

17. hub bolt

18. hub nut

19. tyre 330×114

20.screw M10×60

21. washer 10

22. pin B6×26

23. retainer ring 28

24. Spline housing

25. lock nut

26. screw M6×14

27. lock ring

28. bearing 32017

29. bearing 32019

30. drive gear shaft

31. nut M33×1.5

32. bearing 6207

33. oil seal

34. screw M4×12

35. breather plug

36. tank cover

37. retainer ring 72

38. input shaft

39. lock nut

40. driven gear

41. bearing 30306

42. washer

43. bearing 33206

44. plug 1/2'

45. screw

46. washer 12

47. transmission box plate

48. bolt M6×12

49.steering gear

50. induction ring

51. proximity switch bracket

52. bolt B8×26

53. washer 6

54. bolt M8×70

55. washer 8

56. pin B8×26

57. Bolt M8×30

58. input assembly

59. input shaft assembly

60. oil seal

61. combined washer 16

62. oil addling plug

4.1.2 Disassembling of steering motor

Remove three M8 screws on the steering motor; remove the steering motor from

the steering gear box, at this time, there is steering drive gear and shaft sleeve on the

9

motor shaft. Loose the M10 screw at the end of motor and remove the washer 10,

retainer ring, drive gear and shaft sleeve successively.

4.1.3 Disassembling of diving motor

Remove the four M12 bolts on the drive motor; remove the drive motor from

the gear box.

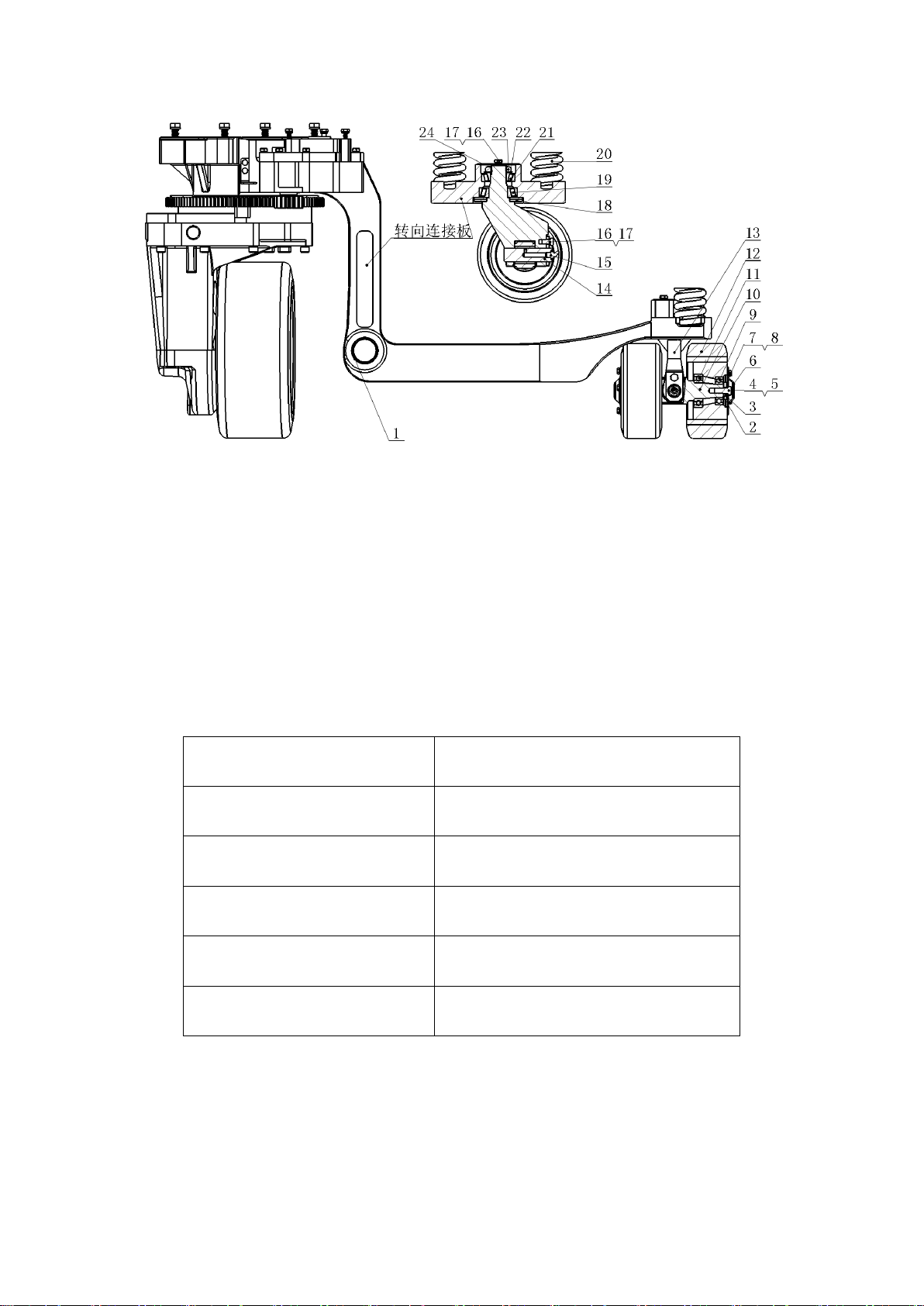

4.2 Rear axle

4.2.1 Working principle

The rear axle is installed on frame through pin at point 1. The rear axle supports

the transmission system and meanwhile, it can reduce the ground pressure of drive

wheel according to the operating surface condition and prevent the drive wheel from

idling.

As a part of rear axle, the balance wheel will rotate with the travelling direction

of truck when steering. The steering knuckle shaft of balance wheel is connected to

the steering connecting plate through two tapered roller bearings. See figure 4-2-1.

When the rear part of the truck is under upwarp condition, install the spring

between steering connecting plate and frame. When the truck is under horizontal

condition, the spring is under compress state. And part of the truck weight is applied

on the steering connecting plate which is transmitted to the balance wheel. Thus the

pressure on the drive wheel is reduced and truck is ensured to contact with ground

with four wheels even on uneven ground.

10

Figure 4-2-1 Rear axle structure

1. bearing

2. adjusting shim

3. block

4. Bolt

5. washer 10

6. guard plate

7. bolt M6x12

8. washer 6

9. bearing 6205-2RS

10. steering shaft

11. bearing 6206-2RS

12. balance wheel

13. steering knuckle

14. steering pin axle

15. lubrication grease fitting

16. bolt M8x16

17. washer 8

18. washer 1

19. bearing 30207

20. spring

21. bearing 30206

22. washer 30

23. nut M30x1.5

24. Steering cover plate

4.3 Steering system

Steering system type

Steering through drive wheel

Steering motor

48V 0.6kw 1350rpm

Deceleration ratio of steering

gear box

1:46

Deceleration ration of gear

transmission

1:5.85

Control type

AC

Steering wheel diameter

φ200mm

The steering system consists of a steering wheel assembly, a electric steering

controller, a steering motor, a steering reduction mechanism and so on. The principle

of the system is below. Angle sensor will send the signal received from the turning of

the hand wheel to steering controller. And then the control voltage which is gotten by

11

the processing of the controller will be put on the two sides of the motor through the

duty ratio of the PWM signal. Through the steering gear deceleration and chain drive

deceleration, the steering wheel will turn a stated angle. The angle degrees with 78°in

forward and 102°in backward will be controlled by the proximity switch on the

steering gearbox. The angle will be feedback and it will be shown on the meter.

4.3.1 Steering wheel assembly

Steering wheel assembly (see fig. 4-3-1) consists of a steering wheel, a steering

bracket, a bearing, a sensor and so on. The function is that it generates a signal of

angle and it doesn’t overcome the force moment of turning, so the turning is easy. The

install position has a 85°degree with the vertical direction. It can not be adjusted

after installment.

Figure 4-3-1 Steering wheel assembly

1. steering wheel

2. steering axle

3. spring

4. Steering bracket assembly

5. bearing 6002-RS

6. elastic coupling

7. steering angle sensor

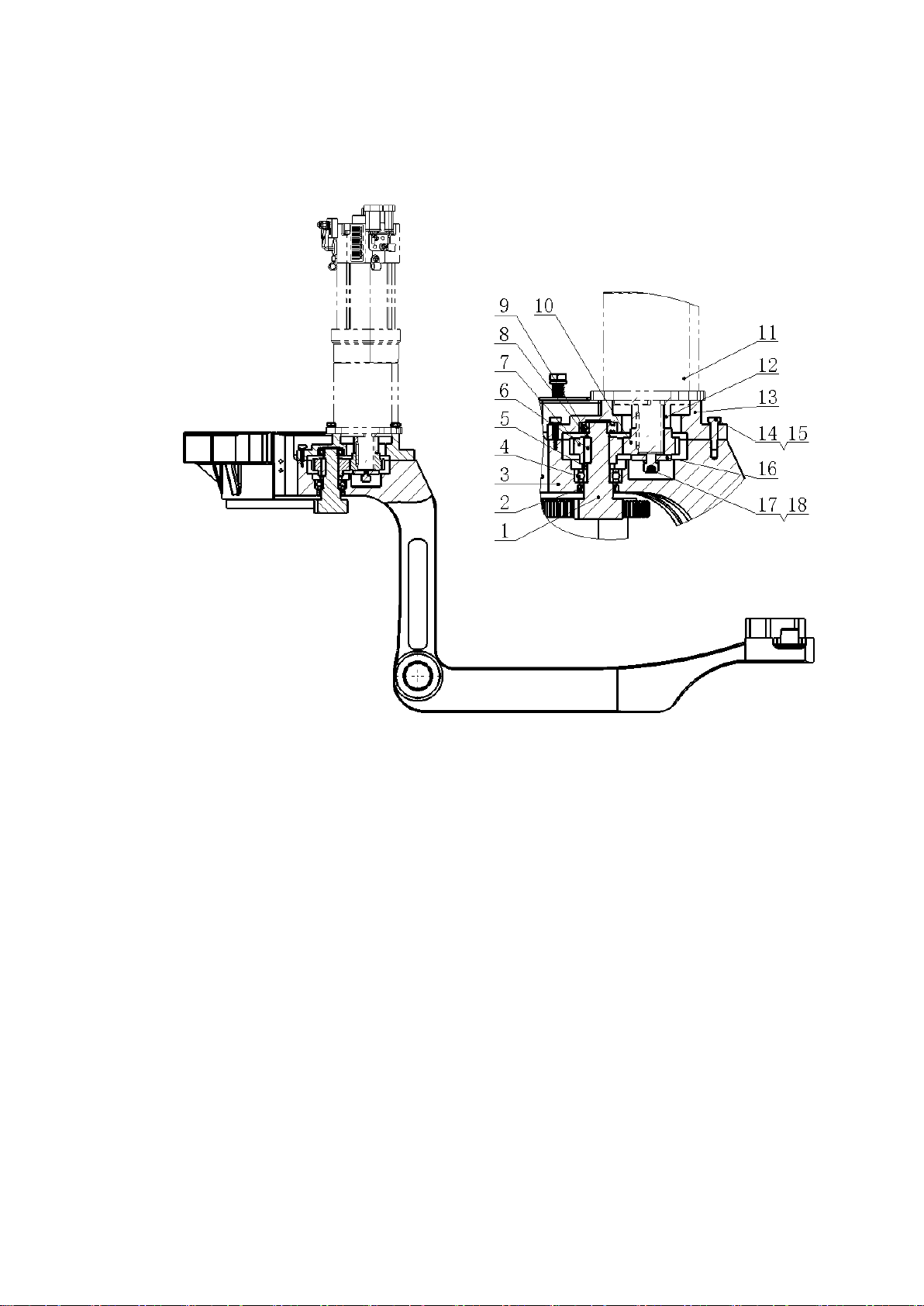

4.3.2 Steering deceleration mechanism

The steering deceleration mechanism (figure 4-3-2) realizes the deceleration of

steering motor. The speed ratio of a pair of meshed gear in the steering gear box is 1:1.

12

The output gear on the output shaft of gear box meshes with steering gear and the

speed ratio is 1:5.85.

Figure 4-3-2 Steering deceleration mechanism

1.output gear

2. oil seal

3. steering connecting plate

4. bearing 6004-2Z

5. shaft sleeve

6. flat key

7. driven gear

8. retainer ring 24

9. bearing 6004-2Z

10. drive gear

11. steering motor

12. shaft sleeve

13. transmission box case cover

14. bolt M8x30

15.washer 8

16. retainer ring

17. screw M10x30

18. washer 10

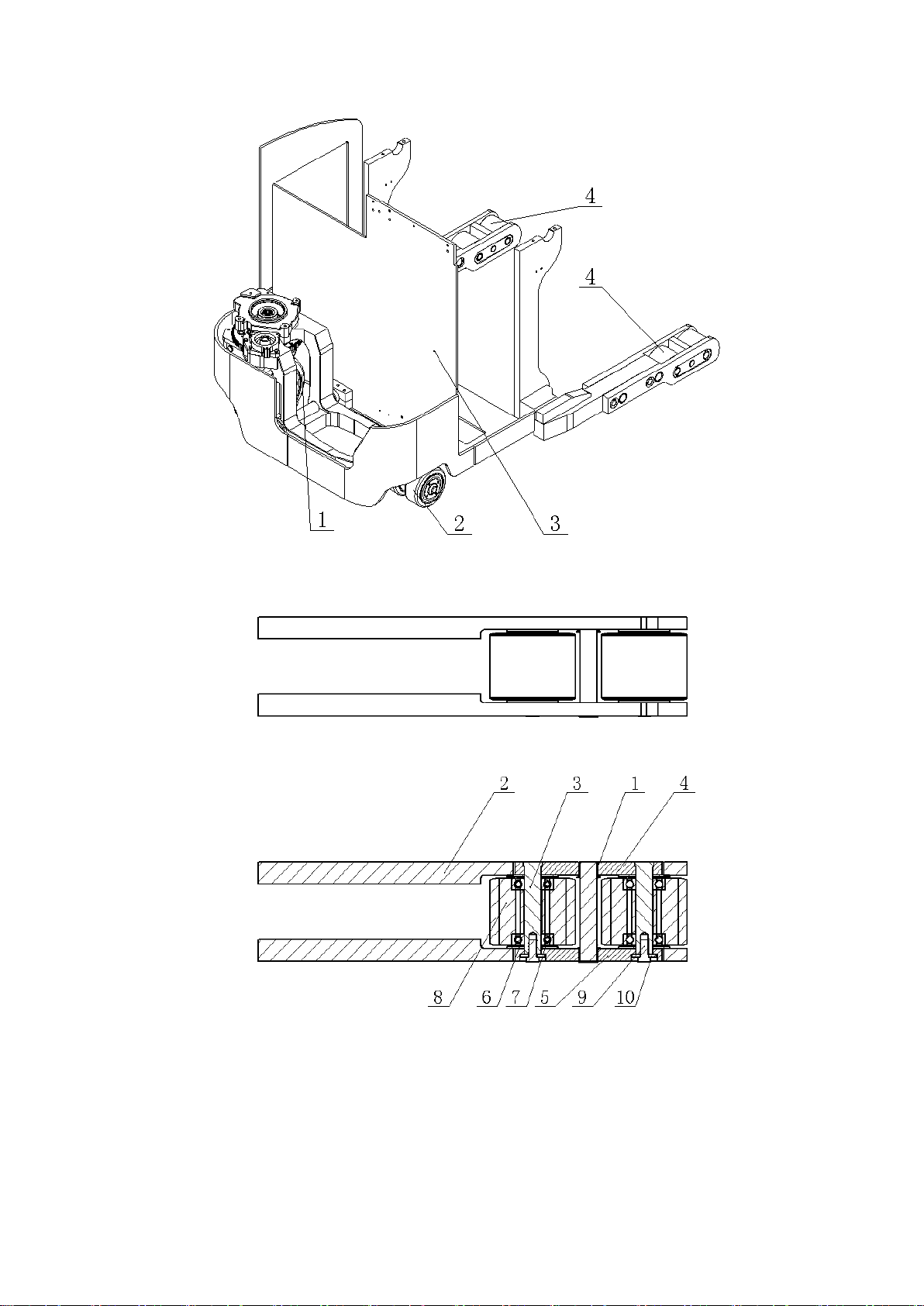

4.4 Supporting wheel assembly

The truck adopts four points supporting structure and the front support is two

symmetrically distributed front load wheel assembly. (See figure 4-4-1).

13

Figure 4-4-1 Diagram of four supporting points

1. Drive wheel 2.Auxiliary wheel 3. Frame 4. Front load wheel assembly

Figure 4-4-2 front load wheel assembly

1. Flange bearing 2. Front leg assembly 3. Pin axle 4. Side plate 1

5. Side plate 2 6. Shim 7. Adjusting shim 8. Load wheel

9. Bolt M12x1.25x25 10. Washer 12

14

The load wheel assembly ( see figure 4-4-2) is mainly made up of 2 bearings,

front leg assembly, pin axle, side plate 1, side plate 2, shims, 2 load wheels, bolt

M12x1.25x25 and washers. Before assembly, apply sufficient grease between 2 load

wheels and change regularly (every 2 month).

4.5 Brake system

4.5.1 Service brake

The truck adopts AC regenerating brake of AC traction motor. There are two

ways to start service brake: one is to release driving operation knob which has weak

brake strength and it is suitable for ordinary condition; the other way is t release brake

pedal which has strong brake strength and it is suitable for emergent condition. (see

figure 4-5-1).

Figure 4-5-1 Service brake

1. Operation knob 2. Brake pedal

4.5.2 Parking brake

15

Electromagnetic parking brake which is on the top of the shaft end cover of the

AC type traction motor is applied on the truck (see figure 4-5-2). The friction disc is

together with motor shaft. When the key is OFF or the emergency switch is pressed,

the truck has no power, then the electromagnetic parking brake‘s electromagnet has

no power. The armature presses the friction disc tightly, the brake hold the traction

motor shaft tightly and then the motor shaft can not rotate and thus the truck is

parking braked.

When travelling, the electromagnetic parking brake should release the friction

disc. Release the parking brake and the brake condition shown on the LCD is released.

Then the truck can be started.

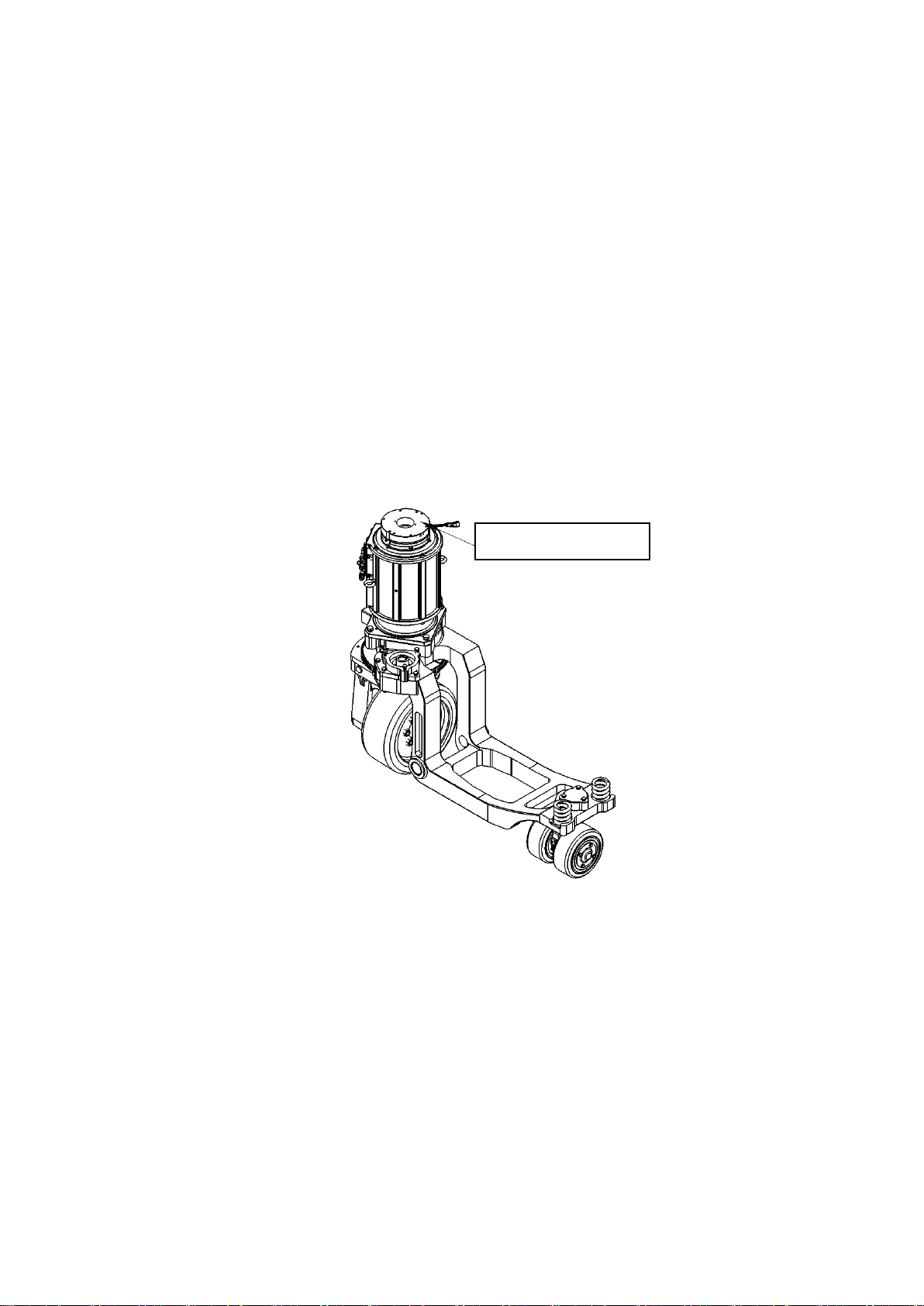

Figure 4-5-2 Diagram of driving unit

Electromagnetic brake

16

Figure 4-5-3 Installment diagram of electromagnetic parking brake

1. Electromagnetic parking brake 2. Socket head cap screw 3. Elastic washer 8

4. Shim 8 5. Flat key 6. Retainer ring 25

See figure 4-5-2 and figure 4-5-3 for electromagnetic parking brake installment.

(1) Fix the electromagnetic parking brake (item 1) onto the top of the shaft end

cover of the traction motor with 3 socket head cap screws M8x16 (item 2). The

tighten torque of the screw is 25Nm and apply anaerobic adhesive GY-340.

(2) Fix the friction disc built-in spine sleeve of the electromagnetic parking brake

with travelling and traction motor shaft through key 8x25 (item 1). Fix the spine

sleeve upper end with retainer 25 (item 6).

Make sure all parts are firmly installed and be sure they can work smoothly.

Notes when assembling electromagnetic parking brake

Make sure the air gap between the basis of the electromagnet and the amature is

0.3mm. Thus electromagnetic brake can brake reliably when getting electricity and

released reliably when power off.

Please see figure 4-5-4 for electromagnetic brake installment dimensions.

Figure 4-3-8 Rated airgap diagram

This manual suits for next models

2

Table of contents

Other HELI Truck manuals