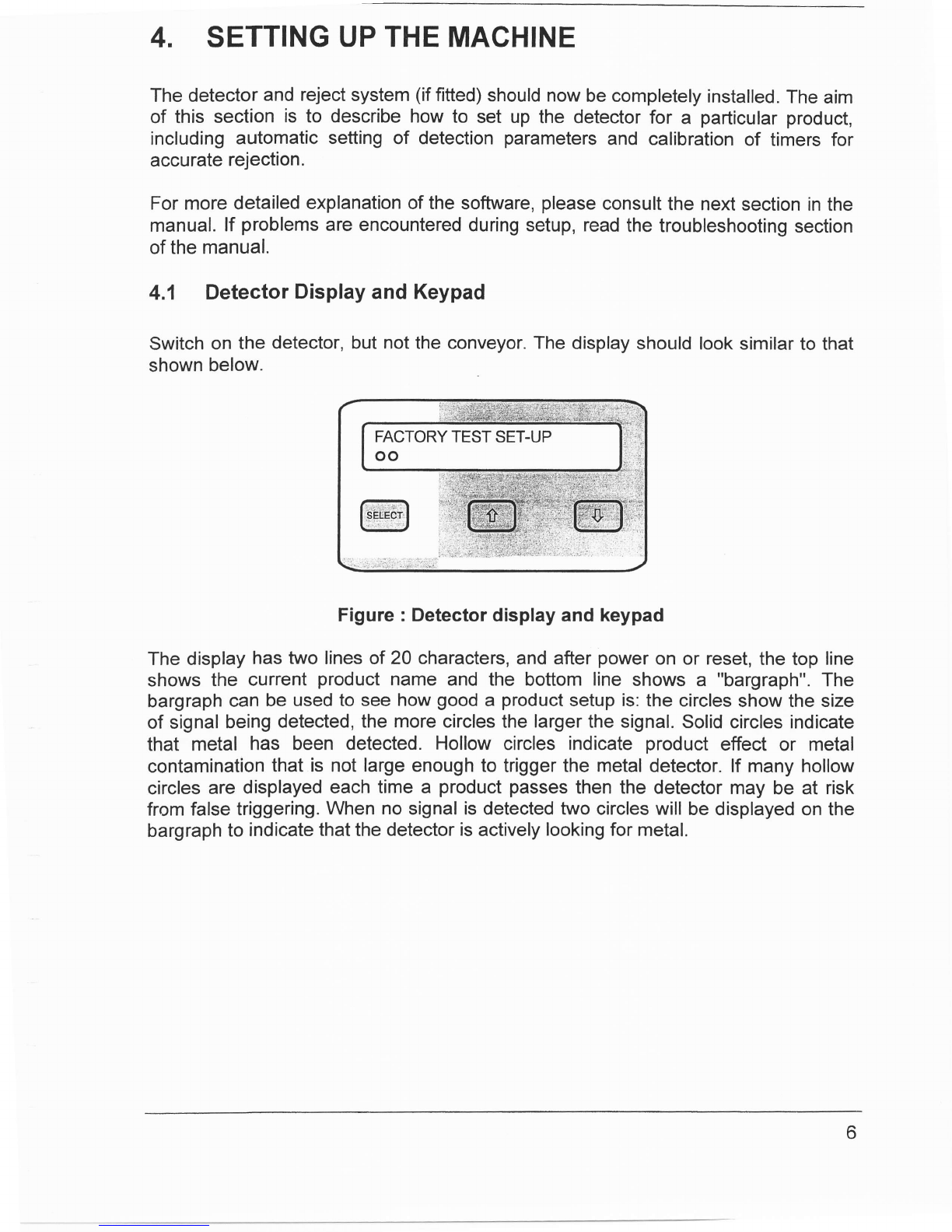

Thekeypad

hasthreekeys,

labelled

from

teft

torightS:F_$B+]!,

!$,,*, tfatany

timeit

is required

to reset

the unit,allthreebuttons

on thekeypad

should

be pressed

simultaneously.

Thiscauses

theunit

toreset

asthough

it

has

just

been

switched

on.

4.2 Initial

Test

Everydetector

is shipped

witha testsample

- a small

piece

of metal

to testthe

detector

with.

Thistest

samplewilleither

beembedded

intheend

of a 30cm

grey

plastic

stick,

orina credit-card-sized,

plastic-laminated

card.

Before

thedetectoris

shipped,

it is setupto see

thissamplewithout

false

triggering

(false

triggering

is

whenthe

detectorindicates

that

ithas

seenmetal

when

none

ispresent,

andis

due

to electrical

noise,

vibration,

large

product

effect,etc.).

This

setupis stored

onthe

detector

under

thename

"FACTORY

TEST

SETUP".

With

thedetector

switched

on,andthe

conveyoroffcheck

the

bargraph

tomake

sure

that

the

machine

is

not

false

triggering.Switch

theconveyor

on.The

bargraph

on

the

metaldetector

shouldshownomoreactivitywith

theconveyor

running

than

whenit

is off.lf thedetectorstartstofalse

trigger,consult

thetrouble-shootingguide.

lf a

reject

mechanism

is fitted,

usetherejectoverrideswitch

in the power

supply

to

activatethe rejectmechanism.lf thisis detected

by the metal

detector

(i.e.

the

bargraph

shows

solidcircles)

thenconsultthetrouble-shooting

guide.

Withthe

conveyor

running,

pass

the

test

sample

throughthe

aperture.

The

detector

isleastsensitive

in

thecentreoftheaperture,

sothebest

testis

topass

the

sample

throughthe

centreof

theaperture.Withateststick

thisisrelatively

easy.With

atest

card,

it may

benecessaryto put

thecard

ona boxto lift

it upintheaperture,

but

makesure

that

the

boxcontainsnometalitself,

by

passing

it

through

theaperture

on

itsownandmakingsure

theheaddoesn't

trigger.When

passing

thetestsample,

makesure

thathands,

rings,

watches

etc.arekept

awayfrom

theaperture.

lf the

detector

does

notseethetestsample,thencheck

thatthe

power

supplyiscorrectly

wired.lfitis

thenconsultLock.

4.3 Product

Setup

The

aimofthis

subsection

isto

get

the

metal

detectortolearn

the

characteristicsofa

particular

product.

Inorderto dothis,some

product

sampleswill

be required.The

description

ofhowtouse

thesoftware

iskeptdeliberatelybriefin

thissubsection,for

moredetail

seethe

nextsectioninthe

manual:

"Using

thesoftware".

Press onthekeypad,

you

shouldbeasked

to enter

a securitycode.The

factoryGfault setting

for this is 2000,so press

FFJfiffi to enterthe code.

The

display

should

thenshow:

Do

sample

test

7