HANDLING

RF INTERFERENCE

Radio Frequency (RF) emissions have been tested to the requirements of FCC 47CFR

Part 15B, FCC 47CFR Part 18, and CISPR 11/EN 55011 (Class A, Group 1). The Eriez

X8 Metal Detector generates an electromagnetic field, which has the potential to

escape. This field may interfere with nearby radio frequency equipment.

If interference becomes a problem, you may need to:

1. Move the Metal Detector or interfering equipment

2. Change the frequency on the Metal Detector

3. Call the Factory for further assistance

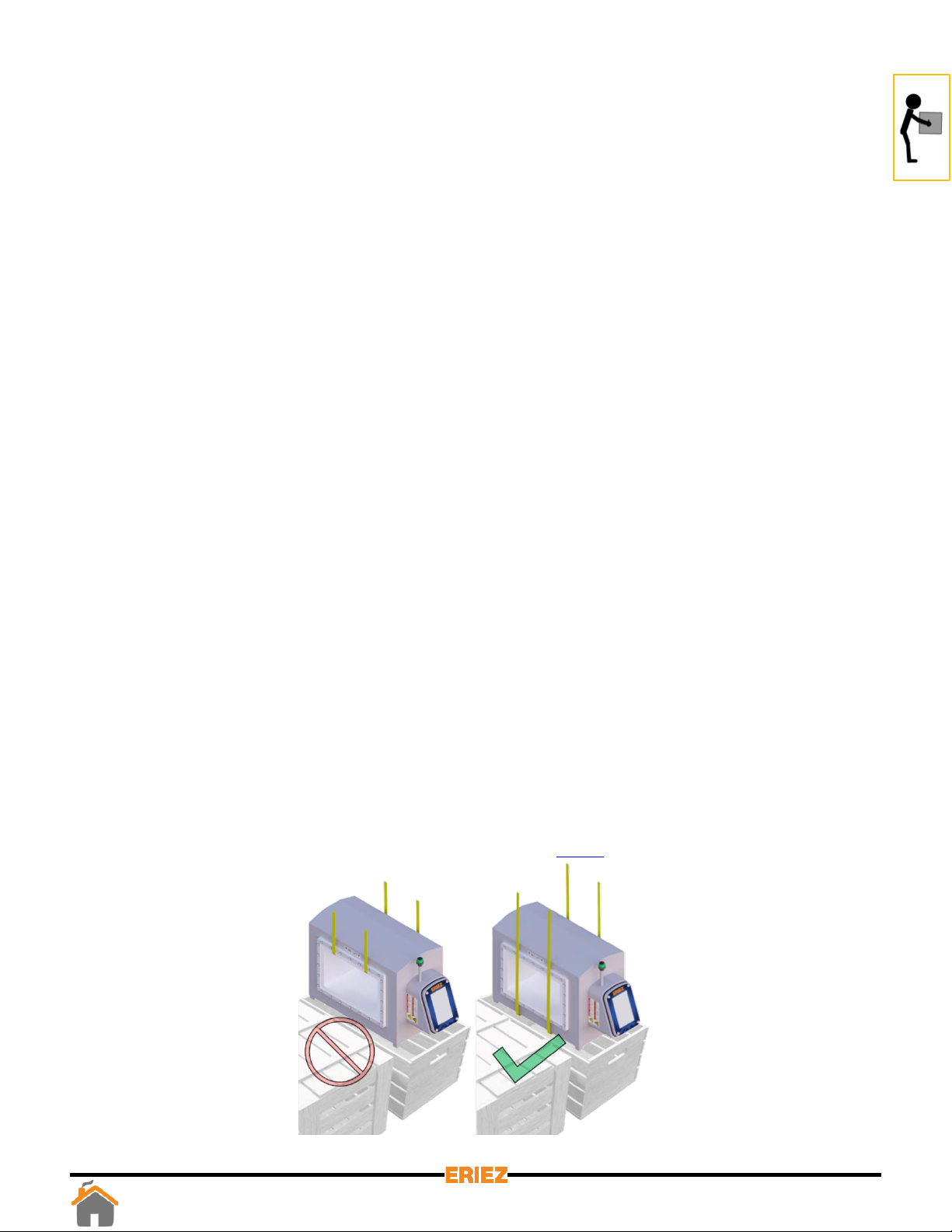

HANDLING INSTRUCTIONS

DO NOT LIFT THE METAL DETECTOR BY INSERTING ANYTHING INTO OR

THROUGH THE TUNNEL.

The inner surface of the tunnel protects the precisely tuned electronic circuit and

internal parts. The tunnel liner also protects the internal parts against water damage.

The integrity of this liner and seal must be maintained. Any damage or distortion to this

surface caused by handling will invalidate the warranty.

When handling, keep the metal detector on the shipping pallet as long as possible.

WHEN REMOVING THE DETECTOR FROM THE SHIPPING PALLET, LIFT ONLY ON

THE DETECTOR HOUSING SURFACES OR SUPPORTING FEET. DO NOT LIFT BY

THE CONTROL HOUSING THAT PROTRUDES FROM THE BODY OF THE METAL

DETECTOR.

If possible, lift the metal detector by using a crane and soft nylon slings running under

the entire metal detector housing as seen below. See Vertical Metal Detector with

Valve Addendum at the end of this reference guide Pg.90 for information concerning

vertical metal detectors.

7

Figure 1: Metal detector handling instructions