Contents

Warning ....................................................................................................................................................1

Contents...................................................................................................................................................2

1. Introduction...........................................................................................................................................3

2. LocoCruiser Standard decoder Series 2...............................................................................................3

3.General Properties of all Decoders........................................................................................................4

3.1 Operating Modes ............................................................................................................................4

3.2 Motor Control ..................................................................................................................................4

3.3 Analogue Mode...............................................................................................................................4

3.4 Functions ........................................................................................................................................4

3.5 Programming ..................................................................................................................................5

3.6 Operational reliability.......................................................................................................................5

4. Installation ............................................................................................................................................5

4.1 Ten Steps for successful decoder installation..................................................................................5

4.1.1 Avoiding heat problems with decoder installations ...................................................................5

4.1.2 Recommended tools for decoder installation............................................................................6

4.2 Requirements for installation...........................................................................................................6

4.3 Installation recommendations .........................................................................................................6

4.4 Locomotive with 8-pin DCC-standard Interface...............................................................................6

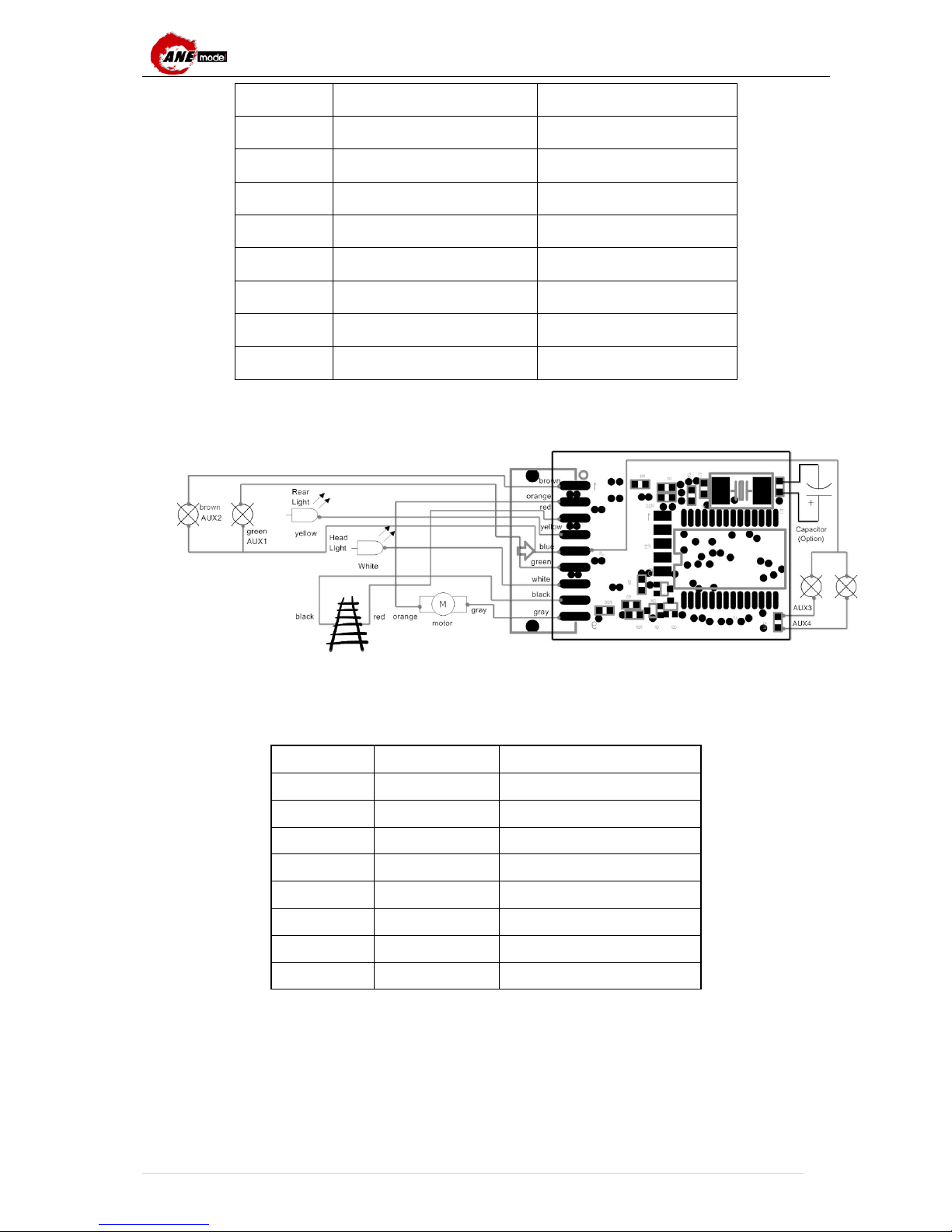

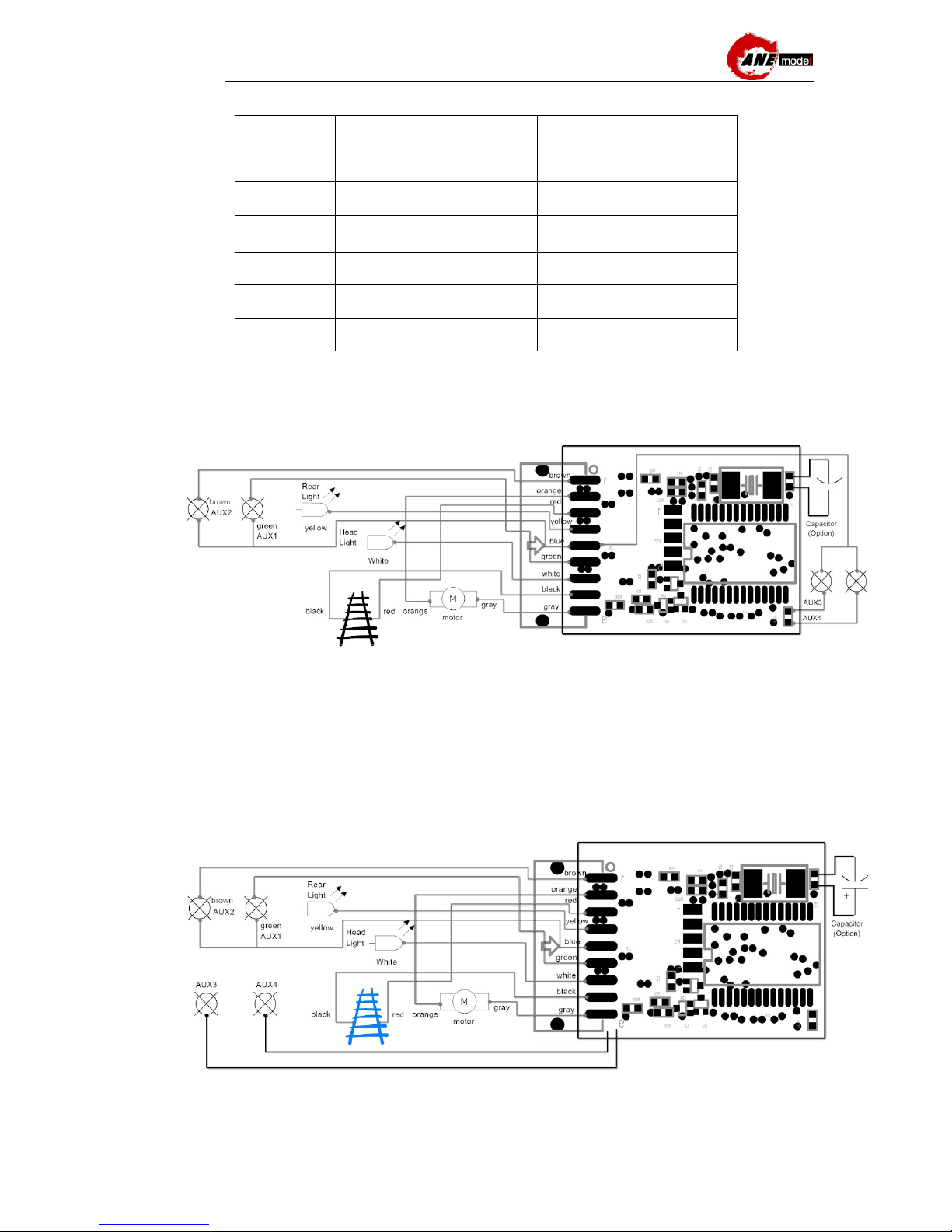

4.4.1 Wiring Diagram for LocoCruiser LC201....................................................................................7

4.5 Locomotive with 6-pin DCC-standard Interface...............................................................................7

4.5.1 Wiring Diagram for LocoCruiser LC202....................................................................................8

4.6 Locomotive with 21-pin DCC-standard Interface.............................................................................8

4.6.1 Wiring Diagram for LocoCruiser LC203....................................................................................8

4.7 Connecting Additional Functions.....................................................................................................8

4.8 Suitable Light Bulbs ........................................................................................................................9

4.9 Suitable locomotive type .................................................................................................................9

5. Initial operation .....................................................................................................................................9

5.1 DCC Mode......................................................................................................................................9

5.1.1 DCC Speed Steps (“flashing lights”).............................................................................................9

5.2 Speed control..................................................................................................................................9

5.2.1 Speed curve setting(Factory Default): .................................................................................9

5.2.2 Speed table mode...................................................................................................................10

5.2.3 Speed model Exchange.......................................................................................................... 11

5.2.4 Acceleration & Deceleration ...................................................................................................11

5.3 DC control..................................................................................................................................... 11

5.3.1 DC control method..................................................................................................................11

5.4 Engine address setting..................................................................................................................11

5.4.1 Engine address ...................................................................................................................... 11

5.4.2 Locomotive engine address setting........................................................................................ 11

5.5 Light effect ....................................................................................................................................12

5.5.1 Turn on/off light.......................................................................................................................12

5.5.2 light effect...............................................................................................................................12

5.6 CV29 setting .................................................................................................................................12

6. Decoder Settings (Programming) .......................................................................................................13

6.1 Configutation Variables (CV).........................................................................................................13

6.1.1 Standardisation in the NMRA .................................................................................................13

6.1.2 Bits and Bytes.........................................................................................................................14