Loctite 988514 User manual

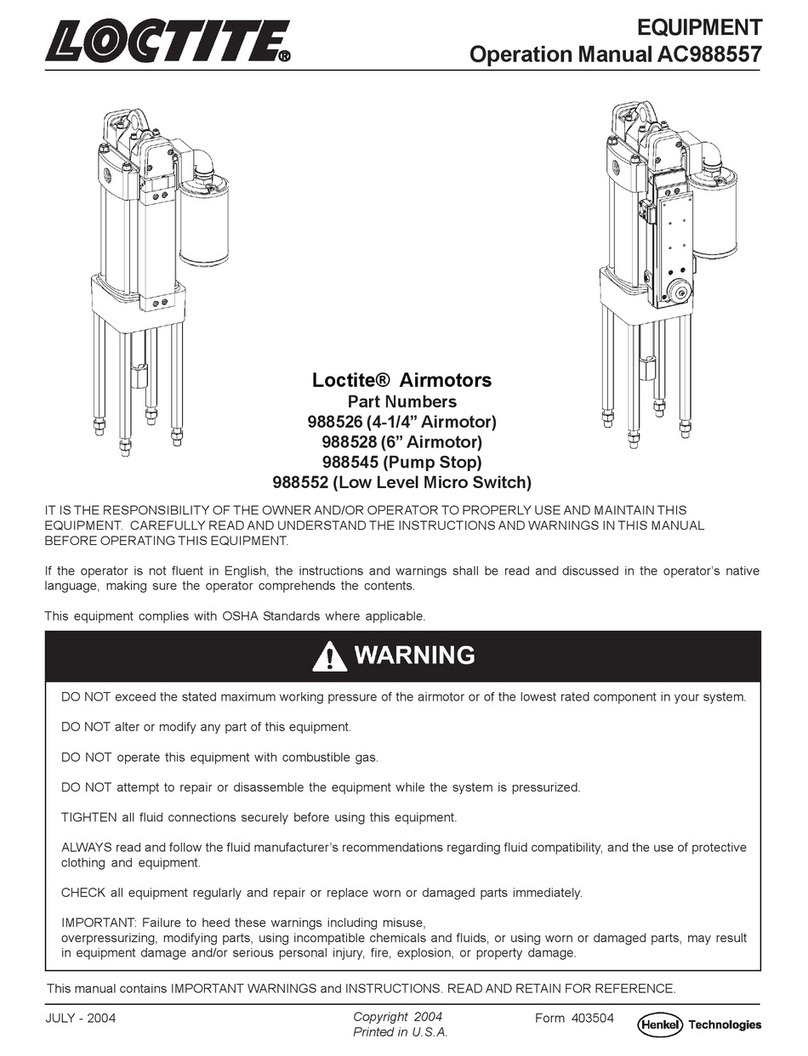

EQUIPMENT

Operation Manual AA988555

IT IS THE RESPONSIBILITY OF THE OWNER AND/OR OPERATOR TO PROPERLY USE AND MAINTAIN THIS

EQUIPMENT. CAREFULLY READ AND UNDERSTAND THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL

BEFORE OPERATING THIS EQUIPMENT.

If the operator is not fluent in English, the instructions and warnings shall be read and discussed in the operator’s native

language, making sure the operator comprehends the contents.

This equipment complies with OSHA Standards where applicable.

SEP - 2004

This manual contains IMPORTANT WARNINGS and INSTRUCTIONS. READ AND RETAIN FOR REFERENCE.

Loctite® Low Viscosity Fluid

Pumps 3:1 and 14:1 Ratios

Part Numbers

988514 (3:1 Carbon Steel, 55 Gal.)

988516 (3:1 Inert, 55 Gal.)

988517 (3:1 Carbon Steel, 5 Gal.)

988519 (3:1 Inert, 5 Gal.)

988520 (14:1 Carbon Steel, 55 Gal.)

988522 (14:1 Inert, 55 Gal.)

988523 (14:1 Carbon Steel, 5 Gal.)

988525 (14:1 Inert, 5 gal.)

988543 (Pump Hoist)

988554 (Wall Mount Kit)

Copyright 2004

Printed in U.S.A.

Form 403502

DO NOT exceed the stated maximum working pressure of the airmotor or of the lowest rated component in your system.

DO NOT alter or modify any part of this equipment.

DO NOT operate this equipment with combustible gas.

DO NOT attempt to repair or disassemble the equipment while the system is pressurized.

TIGHTEN all fluid connections securely before using this equipment.

ALWAYS read and follow the fluid manufacturer’s recommendations regarding fluid compatibility, and the use of protective

clothing and equipment.

CHECK all equipment regularly and repair or replace worn or damaged parts immediately.

IMPORTANT: Failure to heed these warnings including misuse, overpressurizing, modifying parts, using incompatible

chemicals and fluids, or using worn or damaged parts, may result in equipment damage and/or serious personal injury,

fire, explosion, or property damage.

Page Number - 2

Part Nos. 988514, 988516, 988517, 988519

3:1 Low Viscosity Fluid Pumps

SPECIFICATIONS

Airmotor effective dia. in. 2.0

Stroke, in. 4.8

Air inlet 1/4" NPT

Material outlet 1/2" NPT

Liquid to Air Pressure Ratio 3:1

Delivery output, G.P.M. 6

Delivery in cubic inches per cycle 7.9

Suction head, ft. of oil primed pump 25

Minimum air pressure 40 p.s.i.

Maximum air pressure 200 p.s.i.

Max output pressure 600 p.s.i.

Noise level @ 120 psig < 85 dBA

DESCRIPTION

The 3:1 Low Viscosity Fluid Pump is

designed to pump low and medium

viscosity materials. The pump is self-

priming and develops a suction head

up to 25 ft. of oil after priming.

OWNER/OPERATOR

RESPONSIBILITY

It is the owners/operators responsibili-

ty to properly use and maintain this

equipment.

The instructions and warnings con-

tained in this manual shall be read

and understood by the owner/operator

prior to operating this equipment.

If an owner/operator does not under-

stand English,the contents of this

manual shall be explained in the

owners/ operators native language to

assure the owner/operator compre-

hends.

It is the owners/operators responsibili-

ty to maintain the legibility of all warn-

ing and instruction labels.

The owner/operator shall retain this

manual for future reference to Impor-

tant warnings, operating and mainte-

nance Instructions.

SAFETY INFORMATION

Read and understand all warnings,

cautions and instructions before

operating this equipment. Extreme

caution should be used when operat-

ing this equipment as personal injury

and/ or property damage can result

from equipment misuse. Adequate

personal protection is recommended

to prevent splashing of material on the

skin or in the eyes. ALWAYS disconnect

air coupler from pump when the pump

is not being used.

Page Number - 3

3:1 Low Viscosity Fluid Pumps

PRESSURE RELIEF

PROCEDURE

Always perform this procedure when the pump is shut off

and before checking, servicing, installing, cleaning or

repairing any part of this system.

Perform the following procedure:

A. Disconnect the air supply to the pump.

B. Point the dispensing valve away from yourself and

others.

C. Open the dispensing valve into an appropriate container

until the pressure is relieved.

If the above procedure does not relieve the pressure, the

dispensing valve or hose may be restricted. To relieve the

pressure, very slowly loosen the hose end coupling. Then

loosen completely and clear the dispensing valve and/or

hose.

OPERATION

BEFORE USING PUMP

Prior to operation or maintenance a visual inspection shall

be made. Check pump system for leaks, worn or missing

parts.

Any pump that appears to be damaged in any way, is badly

worn or operates abnormally shall be removed from use

until repairs are made. Contact a factory authorized service

center for repairs.

If overpressurizing of the equipment is believed to have

occurred, contact a factory authorized service center for

inspection of the pump.

Annual inspection by a factory authorized service center is

recommended.

USING PUMP

LUBRICATION

An air line filter/regulator/lubricator Is recommended for use

with your Loctite pump to remove harmful dirt and moisture

from your compressor air supply, and to provide automatic air

motor lubrication.

MATERIAL RESTRICTION PREVENTION

Flush the system as required with a compatible solvent to

prevent material buildup when pumping material that dries or

hardens.

The pump was tested in lightweight oil which was left in

to protect the pump from corrosion. Flushing the pump

before connecting it to the system might be desired to

prevent possible contamination of the fluid you are

pumping.

To reduce the risk of injury from splashing or static

sparking when flushing the pump with solvents, always

hold a metal part of the dispensing valve firmly to the side

of a grounded metal pail and operate pump at lowest

possible fluid pressure.

To start pump, turn on the main air supply. Slowly open the

air regulator. Regulate air pressure from 20-40 psig and

throttle to prime pump. Open the dispensing valve to allow

air to be purged from the system. Allow pump to cycle until

fluid without air pockets flows from dispensing valve, then

close dispensing valve.

After pump is primed, adjust air pressure to achieve a

smooth flow of fluid from the dispensing valve. Do not allow

pump to operate when out of material. Pump will accelerate

quickly and run too fast, resulting in costly damage to the

pump.

If the pump accelerates quickly or is running too fast, stop it

immediately. Check the fluid supply and refill it If necessary.

Prime the pump to remove all air from the system, or flush

the pump and relieve pressure.

In a direct supply system, with adequate air pressure sup-

plied to the motor, the pump starts when the gun or dispens-

ing valve is opened and stalls against pressure when it is

closed.

Use the air regulator to control pump speed and fluid pres-

sure. Always use the lowest pressure required to achieve the

desired results. Higher pressures will cause pump packings

to wear prematurely.

MAINTENANCE

To prevent personal injury, perform PRESSURE RELIEF

PROCEDURE before and after operating the pump and

before performing any maintenance.

To prevent personal injury, perform PRESSURE RELIEF

PROCEDURE before and after operating the pump.

Page Number - 4

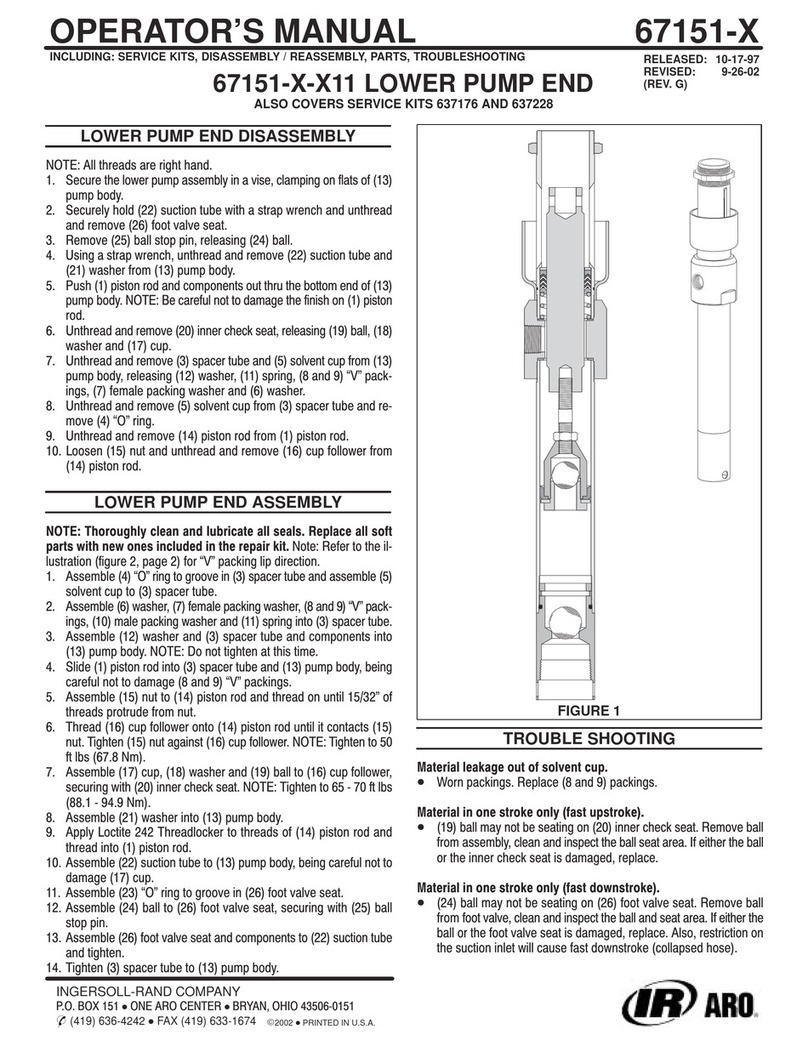

DISASSEMBLY

A. Remove valve cap (Item #1), trip rod pin (Item #2) and

trip collar (Item #21).

B. Remove four tie nuts (Item #45) from tie rods

(Item #44).

C. Unscrew trip sleeve (Item #55) from the trip rod

(Item #28) and lift air valve casting (Item # 4) off of air

cylinder (Item # 29).

D. Remove packing nut (Item #42) and packing cap

(Item #39) from air valve casting. Remove the packing

(Item #40) and packing washer (Item #41).

E. Remove four screws (Item #59) and cover (Item #58)

with the O-ring (Item #57).

F. Remove four screws (Item #38), toggle plate (Item #56),

trip shoe (Item #53) and trip sleeve (Item #55).

G. Remove four valve seat screws (Item #52), four springs

(Item #51), valve guide plate (Item #54) with two springs

(Item #46), two balls (Item #48) and valve slide and seat

kit (Item #49) with gasket (Item #47).

H. Unscrew trip rod packing nut (Item #25) from air valve

casting and remove all packing and gaskets.

I. Unscrew foot valve body (Item #35) and pump tube

(Item #33) from outlet casting (Item #14).

J. Remove air cylinder (Item #29) and air passage tube

(Item #8) from outlet casting.

K. Place wrench on piston seat (Item #18) and connecting

rod (Item #32). Remove piston seat (Item #18) and

piston (Item #17) with two packings (Item #16) and

spring stop (Item #15).

L. Place wrench on piston bolt (Item #5) and piston rod

(Item #27) and remove piston bolt (Item #5), piston

packing (Item #26), two washers (Item #7) and trip rod

(Item #28).

M. Unscrew gland packing nut (Item #9) from outlet casting

and remove all gland seal parts.

3:1 Low Viscosity Fluid Pumps

NOTE

If complete disassembly is required, order the repair kit

and replace ALL gaskets, O-rings and packings.

To prevent personal injury perform PRESSURE RELIEF

PROCEDURE before and after operating and before

performing any disassembly or assembly.

TROUBLESHOOTING

If the following procedures do not correct the problem,

contact a factory authorized service center.

PROBLEMS

AIRMOTOR DOES NOT OPERATE.

• Check air supply to pump.

• Check trip rod pin (Item #2), trip rod (Item #28) and

toggle assembly (Item #56) for breakage or loose parts.

AIR SEEPAGE FROM AIR EXHAUST WHILE PUMP IS NOT

OPERATING

• Check valve slide and seat kit (Item #49) and gasket

(Item #47), trip rod packing (Item #24) and washer

(Item #23). Replace if necessary.

LOSS OF PRESSURE, VOLUME OR CONTINUOUS

OPERATION OF PUMP WHEN NOT IN NORMAL USE.

• Clean piston seat and ball foot valve.

• If worn or damaged, replace piston (Item #17), piston

seat (Item #18) and piston packings (Item #16).

• Check inside diameter of pump tube (Item #33).

If scored, replace pump tube.

ASSEMBLY

To reassemble, perform DISASSEMBLY procedures in

reverse.

Page Number - 5

3:1 Low Viscosity Fluid Pumps

1

221

3

4

5

22

23

24

25

Tighten to 10-15

Ft. Lbs. of Torque.

6

7

26

Use Loctite 510 Gasket

Eliminator on Threads.

27

28

8

29

9

10

30

11

12

10

9

27

13

31

31

13

14

15

32 Use Loctite 510 Gasket

Eliminator on Threads

16

17

33

18

19

20

34

35

1-1/2” NPTF (Male)

1” NPTF (Female)

Page Number - 6

3:1 Low Viscosity Fluid Pumps

36

37

50

46 47 48

49

38

Tighten to 30-40

Inch Lbs. of Torque

39

40

41

42

43

44

45

47

49

51

52

Tighten to 30-40 Inch

Lbs. of Torque

38

Tighten to 30-

40 Inch Lbs. of

Torque

54

55

56

57

58

59

Tighten to 90-100

Inch Lbs. of Torque

IMPORTANT

START FASTENERS BY HAND TO

AVOID STRIPPING THREADS

WHEN REASSEMBLING

TO LUBRICATE AIR VALVE MECHANISM

A. DISCONNECT AIR TO PUMP.

B. PERFORM PRESSURE RELIEF PROCEDURE.

C. REMOVE FOUR COVER SCREWS, COVER PLATE AND

COVER PLATE GASKET.

D. PACK GREASE BEHIND TOGGLE PLATE. USE AP-

PROX. 1-1/2 OUNCES OF N.L.G.I. NO 1 (LIGHT GRADE)

WATER REPELLENT GREASE 220, SP2.

E. IF TOGGLE PLATE HAS BEEN REMOVED FROM AIR

VALVE CASTING, PACK CAVITY WITH GREASE BEFORE

REPLACING TOGGLE PLATE.

F. REPLACE COVER PLATE GASKET, COVER PLATE AND

COVER SCREWS. TIGHTEN TO PREVENT AIR LEAKS.

G. PERIODIC INSPECTION OF PARTS AT LEAST ONCE A

YEAR IS ADVISED.

Page Number - 7

3:1 Low Viscosity Fluid Pumps

55 Gal. Length 5 Gal. Length

60

62

63 61

64

2”

Page Number - 8

3:1 Low Viscosity Fluid Pumps

Item Part No. Part No. Part No. Part No.

No. Description Qty. 988514 988516 988517 988519

1 Valve Cap 1 AA11470 AA11470 AA11470 AA11470

2 Trip Rod Pin 1 AA11472 AA11472 AA11472 AA11472

3 Valve Cap Gasket 1 AA30011 AA30011 AA30011 AA30011

4 Air Valve Casting 1 AA237562 AA237562 AA237562 AA237562

5 Piston Bolt 1 AA245424 AA245424 AA245424 AA245424

6 Gasket 2 AA33014 AA33014 AA33014 AA33014

7 Air Piston Washer 2 AA246499 AA246499 AA246499 AA246499

8 Air Passage Tube 1 AA62383 AA62383 AA62383 AA62383

9 Gland Packing Nut 1 AA245426 AA245426 AA245426 AA245426

10 Quad Ring 1 *AA273526 **AA273527 *AA273526 **AA273527

11 O-ring 2 AA34420 AA34420 AA34420 AA34420

12 O-ring 2 AA34368 AA34368 AA34368 AA34368

13 O-ring 1 *AA245429 *AA245429 *AA245429 *AA245429

14 Outlet Casting 1 AA245401 AA245401 AA245401 AA245401

15 Spring Stop 1 AA12337 AA273616 AA12337 AA273616

16 Piston Seal 2 *AA273528 **AA273529 *AA273528 **AA273529

17 Piston 1 *AA16635 *AA16635 *AA16635 *AA16635

18 Piston Seat 1 *AA12758 AA273617 *AA12758 AA273617

19 Pump Tube Gasket 2 *AA241516 **AA273622 *AA241516 **AA273622

20 Check Ball 1 AA66203 AA273619 AA66203 AA273619

21 Trip Collar 1 AA11471 AA11471 AA11471 AA11471

22 Gasket 1 AA33039 AA33039 AA33039 AA33039

23 Washer 1 AA246500 AA246500 AA246500 AA246500

24 Packing 1 AA236835 AA236835 AA236835 AA236835

25 Trip Rod Packing Nut 1 AA245425 AA245425 AA245425 AA245425

26 Air Piston Packing 1 AA261078 AA261078 AA261078 AA261078

27 Piston Rod 1 AA241510 AA273620 AA241510 AA273620

28 Trip Rod 1 AA91528 AA91528 AA91528 AA91528

29 Air Cylinder 1 AA246496 AA246496 AA246496 AA246496

30 Cylinder Ring 2 AA246497 AA246497 AA246497 AA246497

31 U-cup 1 *AA273524 **AA273525 *AA273524 **AA273525

32 Connecting Rod 1 AA16636 AA273618 AA16636 AA273618

33 Pump Tube 1 AA241511 AA273621 AA241511 AA273621

34 Ball Stop 1 AA241518 AA273624 AA241518 AA273624

35 Foot Valve Body 1 AA241517 AA273623 AA241517 AA273623

36 Muffler 1 AA236833 AA236833 AA236833 AA236833

37 Muffler Cover 1 AA236615 AA236615 AA236615 AA236615

38 Screw 6 AA236869 AA236869 AA236869 AA236869

39 Packing Cap 1 AA11905 AA11905 AA11905 AA11905

40 Packing 1 AA34110 AA34110 AA34110 AA34110

41 Packing Washer 1 AA48237 AA48237 AA48237 AA48237

42 Packing Nut 1 AA11904 AA11904 AA11904 AA11904

43 Packing Nut Gasket 1 AA30003 AA30003 AA30003 AA30003

44 Tie Rod 4 AA241512 AA241512 AA241512 AA241512

PARTS LIST FOR 3:1 LOW VISCOSITY FLUID PUMPS

Page Number - 9

3:1 Low Viscosity Fluid Pumps

Item Part No. Part No. Part No. Part No.

No. Description Qty. 988514 988516 988517 988519

PARTS LIST FOR 3:1 LOW VISCOSITY FLUID PUMPS

45 Nut 4 AA51009 AA51009 AA51009 AA51009

46 Spring 2 AA56038 AA56038 AA56038 AA56038

47 Valve Gasket 1 AA38162 AA38162 AA38162 AA38162

48 Steel Ball 2 AA69102 AA69102 AA69102 AA69102

49 Slide and Seat Kit 1 AA83063 AA83063 AA83063 AA83063

50 Air Nipple 1 AA238394 AA238394 AA238394 AA238394

51 Spring 4 AA55138 AA55138 AA55138 AA55138

52 Valve Seat Screw 4 AA236870 AA236870 AA236870 AA236870

53 Trip Shoe 1 AA11475 AA11475 AA11475 AA11475

54 Valve Guide Plate 1 AA45605 AA45605 AA45605 AA45605

55 Trip Sleeve 1 AA11947 AA11947 AA11947 AA11947

56 Toggle Assembly 1 AA91331S AA91331S AA91331S AA91331S

57 O-ring 1 AA34158 AA34158 AA34158 AA34158

58 Cover 1 AA236286 AA236286 AA236286 AA236286

59 Screw 4 AA236868 AA236868 AA236868 AA236868

60 Suction Tube 1 AA246782 AA273692 n/a n/a

61 Foot Valve Assembly 1 AA85765 AA273688 n/a n/a

62 Foot Valve Body 1 AA246778 AA273691 n/a n/a

63 Pin 1 AA13056 AA273689 n/a n/a

64 Check Ball 1 AA66728 AA273690 n/a n/a

65 Suction Tube 1 n/a n/a AA273569 AA273569

*Included in Repair Kit No. 988833

**Included in Repair Kit No. 988834

Page Number - 10

Part Nos. 988520, 988522, 988523, 988525

14:1 Low Viscosity Fluid Pumps

SAFETY INSTRUCTIONS

For professional use only. Observe all warnings. Read and

understand all instructions before operating equipment. Extreme

caution should be used when operating this equipment as personal

injury and/or property damage can result from equipment misuse.

This equipment generates very high fluid pressure. Extreme caution

should be used when operating this equipment as material from

dispensing valve or leaks from loose or ruptured components can

inject fluid through the skin and into the body causing serious bodily

injury including possible need for amputation. Adequate protection is

recommended to prevent splashing of material onto the skin or into

the eyes.

IMPORTANT: If any fluid appears to penetrate the skin, get emergen-

cy medical care immediately! Do not treat as a simple cut. Tell

attending physician exactly what fluid was injected.

INSPECTION INSTRUCTIONS

If overpressurizing of the equipment is believed to have occurred,

contact the factory authorized warranty and service center

nearest you for inspection of the pump.

Specialized equipment and knowledge is required for repair of this

pump. Contact the factory authorized warranty and service center

nearest you for repair or adjustments other than maintenance

specified in this manual.

Annual inspection by the factory authorized warranty and service

center nearest you is recommended.

A list of factory authorized warranty and service centers is

available upon request.

ALWAYS read and follow the fluid and solvent manufactur-

er’s recommendations regarding the use of protective clothing

and equipment.

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including splashing

into the eyes or onto the skin, always follow this procedure.

Whenever you shut off the pump, when checking or servicing

any part of the system, and when installing, cleaning or

changing any part of the system.

1. Disconnect air to the pump.

2. Point the dispensing valve away from yourself and others.

3. Open the dispensing valve into an appropriate container

until pressure is relieved.

If you suspect that the dispensing valve or hose is completely

clogged or that pressure has not been fully relieved after

following the above procedure, VERY SLOWLY loosen the

hose end coupling to relieve pressure gradually, then loosen

completely. Now clear the valve or hose.

ALWAYS follow the pressure relief procedure after shutting

off the pump, when checking or servicing any part of the

system, and when installing, cleaning or changing any part of

the system.

ALWAYS check equipment for proper operation before each

use, making sure safety devices are in place and operating

properly. DO NOT alter or modify any part of the equipment as

this may cause a malfunction and result In serious bodily injury.

NEVER point the dispensing valve at any part of the body or at

another person.

NEVER try to stop or deflect material from dispensing valve or

leaking connection or component with your hand or body.

Specifications:

14:1 Ratio

Output - 1.7 cu./ in./Cyl.

Min. Air Pressure - 30 PSI

Max. Air Pressure - 160 PSI

Max. Output Pressure - 2250

Page Number - 11

Flush the supply lines and hoses with mineral spirits or oil based

solvent and blow dry with air before connecting them to the

system. This is to purge any contaminants such as dirt, moisture, or

metal shavings that could damage the pump or system components.

The pump was tested in lightweight oil which was left in it to

protect the pump from corrosion. Flushing of the pump before

connecting it to the system might be desired to prevent contamina-

tion of the fluid you are pumping.

DAMAGED PUMPS

Any pump that appears to be damaged in any way, is badly worn

or operates abnormally shall be removed from use until repairs are

made. Contact the factory authorized warranty and service center

nearest you for repairs.

INSTALLATION

An air line filter/regulator/lubricator is recommended for use with

your pump to remove harmful dirt and moisture from the com-

pressed air supply, and to provide automatic lubrication to the air

motor.

This pump can develop 2250 PSI working pressure at 160 PSI

maximum incoming air pressure. Be sure that all system equip-

ment and accessories are rated to withstand the maximum

working pressure of this pump. DO NOT exceed the maximum

working pressure of the lowest rated component in the system.

OPERATION

To start the pump, turn on the main air supply, slowly open the air

regulator until the pump runs smoothly. Open the dispensing valve

to allow air to be purged from the system. Allow pump to cycle until

fluid without air pockets flows from dispensing valve, then close

dispensing valve.

In a direct supply system, with adequate air pressure supplied to

the air motor, the pump starts when the dispensing valve is opened

and stalls against pressure when dispensing valve is closed.

Use the air regulator to control pump speed and fluid pressure.

Always use the lowest pressure required to achieve the desired

results. Higher pressures will cause pump packings to wear

prematurely.

If the pump accelerates rapidly or is running too fast, stop it

immediately. Check the fluid supply and refill if necessary. Prime the

pump to remove all air from the system or flush the pump and

relieve pressure.

MAINTENANCE

To reduce the risk of serious bodily injury or property damage,

NEVER exceed the maximum air or fluid working pressure of the

lowest rated system component.

To reduce the risk of serious bodily Injury, ALWAYS follow the

pressure relief procedure warning whenever you stop the pump

and before checking or repairing any part of the system.

14:1 Low Viscosity Fluid Pumps

Pump Dimension "A"

988520, 988522 33-15/16"

988523, 988525 13"

To reduce the risk of injury from splashing or static sparking

when flushing the pump with mineral spirits or oil based

solvent, always hold a metal part of the dispensing valve

firmly to the side of a grounded metal pail and operate pump at

lowest possible fluid pressure.

Page Number - 12

DISASSEMBLY INSTRUCTIONS

1. Remove Valve Cap (Item #1) and Trip Rod Pin (Item #2).

2. Unscrew Tie Rod Packing Nuts (Item #52) from Tie Rods

(Item #51) and lift Air Valve Casting (Item #4) off of Air Cylinder

(Item #12).

3. Remove Packing Nut (Item #49) and Packing Cap (Item #46)

from Air Valve Casting.

4. Remove four Screws (Item #66) and Cover (Item #65).

5. Remove four Screws (Item #45), Toggle Plate (Item #63) and

Trip Shoe (Item #61) and Trip Sleeve (Item #62).

6. Remove four Screws, (Item #60), Springs (Item #59), Valve

Guide Plate (Item #58) and Valve Slide, Seat and Gasket (Item

#56).

7. Unscrew Trip Rod Packing Nut (Item #27) from Air Valve

Casting and remove all packing parts.

8. Unscrew Lower Pump Tube (Item #39) from Pump Tube.

9. Unscrew Pump Tube Adapter (Item #17) and Pump Tube from

Outlet Body (Item #15).

10. Place wrenches on Nut (Item #38) and wrench flats of Pump

Piston Rod (Item #21) and unscrew Nut. Remove Piston

Check (Item #37) and Pump Piston (Item #36).

11. Remove Cotter Pin (Item #19) and unscrew Pump Piston Rod

(Item #21) from Adapter Nipple (Item #20).

12. Remove Air Cylinder (Item #12) and Air Passage Tube

(Item #13) from Outlet Body (Item #15).

13. Extend Piston Rod (Item #11) out bottom of Outlet Body. Place

wrenches on Piston Bolt (Item #7) and on wrench flats of

Piston Rod and unscrew Piston Rod (Item #11). Withdraw

Piston from Pump Gland.

14. Unscrew Gland Nut (Item #28) from Outlet Body (Item #15)

and remove all gland parts.

15. To reassemble, reverse procedure. Tighten fasteners per

torque specifications supplied. Important: To prevent damage

to Pump Packings and to help increase Packing Life, Lube Air

Cylinder and Piston Rod before assembly.

Notes:

1. If complete disassembly is required, replace all Gaskets, O-

rings and Packings.

2. Before tightening four Valve Seat Screws (Item #60), align the

Valve Slide, Seat and Gasket (Item #56), Valve Seat Gasket

(Item #53) and Air Valve Casting (Item #4) by placing a rod or

ink pen through the Center Port Hole.

3. Start all fasteners by hand to avoid stripping threads when

reassembling.

14:1 Low Viscosity Fluid Pumps

1

2

3

23

4

5

7

9

12

6

8

10

11

24

25

26

27

13

6

8

14

5

28

29

15

30

16

17

18

19

20

31

32

33

34

21

22

DO NOT operate these units with combustible gas.

Page Number - 13

14:1 Low Viscosity Fluid Pumps

1. Pump does not operate. Check air supply to pump.

Replace Trip Rod Pin (Item #2), Trip Rod

(Item #14) and Toggle Plate (Item #63).

2. Air seepage from air exhaust port while Replace Valve Slide, Seat & Gasket (Item #56),

pump is not operating. Trip Rod Packing (Item #26) and Gasket

(Item #24).

3. Loss of pressure, volume or continuous Clean piston check and ball foot valve.

operation of pump when not in normal Check Piston (Item #36), Piston Check

use. (Item #37) and 0-rings (Item #33). Replace if

worn or damaged.

Check inside diameter of Lower Pump

Tube (Item #39), replace if scored.

Inspect lubricant supply line for leaks or

breaks.

4. Excessive amount of air entrapped in Replace two Gland Packings (Item #30),

lubricant or excessive amount of lubri- Gland Gasket (Item #31) and U-cup Packing

cant coming from air exhaust. (Item #33).

Note: Some lubricant exhausts with air

normally.

5. Pump will not stall against fluid pressure Replace O-rings(Item #33).

on "Up" stroke. Clean Piston Check (Item #37) and seating

surface of Piston (Item #36).

6. Pump will not stall against fluid pressure Clean ball foot valve.

on "Down" stroke.

TROUBLESHOOTING

16

17

18

19

20

21

22

35

36

37

38

39

40

41

42

Page Number - 14

14:1 Low Viscosity Fluid Pumps

56

TO LUBRICATE AIR VALVE MECHANISM

DISCONNECT AIR TO PUMP. REMOVE THE FOUR

COVER SCREWS, COVER PLATE AND COVER PLATE

GASKET.

REMOVE AND DISASSEMBLE THE AIR VALVE CASTING

FROM THE PUMP.

THE AIR VALVE CASTING SHOULD BE CLEANED OR

FLUSHED TO REMOVE ANY CHIPS, OR OTHER

FOREIGN PARTICLES PRIOR TO RE-ASSEMBLY.

BEFORE REPLACING THE TOGGLE ASSEMBLY, PACK

CAVITY WITH GREASE.

USE N.L.G.I. No. 1 (LIGHT GRADE) WATER REPELLENT

GREASE. APPROX 1-1/2 OUNCES.

REPLACE COVER GASKET, COVER, AND SCREWS.

TIGHTEN TO AVOID AIR LEAKS.

PERIODIC INSPECTION OF PARTS AT LEAST ONCE

EACH YEAR IS ADVISABLE.

IMPORTANT: Start fasteners by hand to

avoid stripping threads when reas-

sembling.

43

44

45

46

47

48

49

50

51

52

53

54

55

56 57

58

59

60

45

61

62 63

65

64

66

Page Number - 15

14:1 Low Viscosity Fluid Pumps

Item Part No. Part No. Part No. Part No.

No. Description Qty. 988520 988522 988523 988525

1 Valve Cap 1 AA11470 AA11470 AA11470 AA11470

2 Trip Rod Pin 1 AA11472 AA11472 AA11472 AA11472

3 Valve Cap Gasket 1 AA30011 AA30011 AA30011 AA30011

4 Air Valve Casting 1 AA237562 AA237562 AA237562 AA237562

5 O-ring 2 AA34368 AA34368 AA34368 AA34368

6 Air Cylinder Gasket 2 AA33014 AA33014 AA33014 AA33014

7 Piston Bolt 1 AA13300 AA13300 AA13300 AA13300

8 Air Piston Washer 2 AA48212 AA48212 AA48212 AA48212

9 Air Piston Packing 1 AA34090 AA34090 AA34090 AA34090

10 Washer 1 AA48468 AA48468 AA48468 AA48468

11 Piston Rod 1 AA238156 AA238156 AA238156 AA238156

12 Air Cylinder 1 AA61041 AA61041 AA61041 AA61041

13 Air Passage Tube 1 AA61502 AA61502 AA61502 AA61502

14 Trip Rod 1 AA91964 AA91964 AA91964 AA91964

15 Outlet Body 1 AA40579 AA273686 AA40579 AA273686

16 Gasket 1 AA31002 AA273677 AA31002 AA273677

17 Pump Tube Adapter 1 AA14374 AA273673 AA14374 AA273673

18 O-ring 3 *AA273532 **AA273533 *AA273532 **AA273533

19 Cotter Pin 1 AA68900 AA273685 AA68900 AA273685

20 Adapter 1 AA14077 AA273667 AA14077 AA273667

21 Piston Rod 1 AA14482 AA273675 AA14482 AA273675

22 Pump Tube 1 AA61540 AA273683 AA61540 AA273683

23 Trip Collar 1 AA11471 AA11471 AA11471 AA11471

24 Gasket 1 AA33039 AA33039 AA33039 AA33039

25 Trip Rod Packing Gasket 1 AA236616 AA236616 AA236616 AA236616

26 Trip Rod Packing 1 AA236835 AA236835 AA236835 AA236835

27 Trip Rod Packing Nut 1 AA245425 AA245425 AA245425 AA245425

28 Gland Nut 1 AA14090 AA273669 AA14090 AA273669

29 Gland Packing Washer 1 AA48448 AA273679 AA48448 AA273679

30 Gland Packing 2 *AA273536 **AA273537 *AA273536 **AA273537

31 Gland Gasket 1 *AA31050 **AA273678 *AA31050 **AA273678

32 Gland Packing Spacer 1 AA14087 AA273668 AA14087 AA273668

33 U-cup 1 *AA273605 **AA273606 *AA273605 **AA273606

34 Washer 1 AA48474 AA273680 AA48474 AA273680

35 O-ring 2 *AA273534 **AA273535 *AA273534 **AA273535

36 Pump Piston 1 *AA14372 **AA273672 *AA14372 **AA273672

37 Piston Check 1 *AA14375 **AA273674 *AA14375 **AA273674

38 Nut 1 AA51304 AA273681 AA51304 AA273681

39 Lower Pump Tube 1 AA14371 AA273671 AA14371 AA273671

40 Ball Stop 1 AA57120 AA273682 AA57120 AA273682

41 Check Ball 1 AA66203 AA273619 AA-66203 AA-273619

42 Foot Valve Body 1 AA14370 AA273670 AA14370 AA273670

43 Muffler 1 AA236833 AA236833 AA236833 AA236833

44 Muffler Cover 1 AA236615 AA236615 AA236615 AA236615

45 Screw 6 AA236869 AA236869 AA236869 AA236869

PARTS LIST FOR 14:1 LOW VISCOSITY FLUID PUMPS

Page Number - 16

14:1 Low Viscosity Fluid Pumps

Item Part No. Part No. Part No. Part No.

No. Description Qty. 988520 988522 988523 988525

PARTS LIST FOR 14:1 LOW VISCOSITY FLUID PUMPS

46 Packing Cap 1 AA11905 AA11905 AA11905 AA11905

47 Plunger Packing 1 AA34110 AA34110 AA34110 AA34110

48 Packing Washer 1 AA48237 AA48237 AA48237 AA48237

49 Packing Nut 1 AA11904 AA11904 AA11904 AA11904

50 Packing Nut Gasket 1 AA30003 AA30003 AA30003 AA30003

51 Tie Rod 4 AA10294 AA10294 AA10294 AA10294

52 Nut 4 AA51009 AA51009 AA51009 AA51009

53 Valve Gasket 1 AA38162 AA38162 AA38162 AA38162

54 Air Nipple 1 AA238394 AA238394 AA238394 AA238394

55 Spring 2 AA56038 AA56038 AA56038 AA56038

56 Slide and Seat Kit 1 AA83063 AA83063 AA83063 AA83063

57 Steel Ball 2 AA69102 AA69102 AA69102 AA69102

58 Valve Guide Plate 1 AA45605 AA45605 AA45605 AA45605

59 Spring 4 AA55138 AA55138 AA55138 AA55138

60 Valve Seat Screw 4 AA236870 AA236870 AA236870 AA236870

61 Trip Shoe 1 AA11475 AA11475 AA11475 AA11475

62 Trip Sleeve 1 AA11947 AA11947 AA11947 AA11947

63 Toggle Assembly 1 AA91331S AA91331S AA91331S AA91331S

64 O-ring 1 AA34158 AA34158 AA34158 AA34158

65 Cover 1 AA236286 AA236286 AA236286 AA236286

66 Screw 4 AA236868 AA236868 AA236868 AA236868

*Included in Repair Kit No. 988835

**Included in Repair Kit No. 988836

Page Number - 17

Part No. 988554

Wall Mount Kit

Item Part

No. Description Qty. No.

1 Bracket 1 AA241401

2 Lockwasher 3 AA66186

3 Hex Head Screw (1/4-20 x 3/4) 3 AA50018

PARTS LIST

1

2

3

Page Number - 18

Part No. 988543

Pump Hoist

SPECIFICATIONS

HEIGHT LOWERED - 70-1/2”

HEIGHT RAISED - 108-1/2 lbs.

LIFT CAPACITY - 400 LBS. MAX.

ROTATION - 360°

10

8

9

Item Part

No. Description Qty. No.

1 Hex Head Screw 1 AA50033

(1/4-20 x 1)

2 Washer 2 AA48083

3 Hex Nut 1 AA51010

4 Support Tube 1 AA61453

5 Chain 1 AA70358

6 Anchor Shackle 1 AA68543

7 Hoist Hook 1 AA68544

8 Eye Bolt 1 AA68531

9 Adapter 1 AA236975

10 Round Head Screw 2 AA50618

(6-32 x 1-1/8)

11 Clamp 2 AA360226

12 Hex Nut (6-32) 2 AA51403

13 Hex Head Screw 1 AA50044

(3/8-16 x 1)

14 Tee Casting 1 AA40444

15 Tube Cap 1 AA40447

16 Set Screw 1 AA50522

17 Support Tube Assembly 1 AA91632

18 Support Tube 1 AA61439

19 Elbow 1 AA11832

20 Air Nipple 1 AA653106

21 Airline Pipe 1 AA67275

22 Tube Gasket 1 AA33050

23 Plug 1 AA12511

24 Tube Cap 1 AA40446

25 Base Casting 1 AA40445

26 Packing 1 AA34327

27 Set Screw 1 AA50505

28 Packing 1 AA236535

PARTS LIST FOR PUMP HOIST

OPERATING AIR PRESSURE

50 P.S.I.G. MIN. TO 200 P.S.I.G. MAX.

5/0 STRAIGHT LINK CHAIN CAN BE

ADJUSTED TO DESIRED HEIGHT.

1

3

13

14

5

16

18

15

17

7

6

19

20

11

12 21

27

28

25

26 22

23

24

2

4

3/8” NPT

Page Number - 19

Pump Hoist

INSTALLATION

Base casting can be used as a template for location of anchor bolts. Position of pump hoist in respect to drum location for

contractor’s rigs. Arm must be adjusted for side opening drums.

OPERATION

Fasten Adapter (Item #9) and Eyebolt (Item #8) to top of Ball Pump. Insert Hook (Item #7) through Eyebolt (Item #8), Adjust

length of chain (Item #5).

Attach socket of air supply to plug.

(Operating air pressure 50 P.S.I.G. min. to 200 P.S.I.G. Max.) Restrictor in base of air inlet prevents pump hoist from lifting

too rapidly.

IMPORTANT: Socket must remain connected to hold hoist in the raised position.

Remove socket to lower hoist. Restrictor in the base of air inlet permits the hoist to lower slowly. The plug located in the

base casting can be removed for cleaning the air restrictor.

Page Number - 20

WARRANTY

Henkel expressly warrants that all products referred to in this Instruction Manual for (Item 988514 (3:1 Pump), 988516 (3:1

Pump), 988517 (3:1 Pump), 988519 (3:1 Pump), 988520 (14:1 Pump), 988522 (14:1 Pump), 988523 (14:1 Pump) 988525

(14:1 Pump), 988543 (Pump Hoist), 988554 (Wall Mount Kit)) (hereafter called “Products”) shall be free from defects in

materials and workmanship. Liability for Henkel shall be limited, as its option, to replacing those Products which are shown

to be defective in either materials or workmanship or to credit the purchaser the amount of the purchase price thereof (plus

freight and insurance charges paid therefor by the user). The purchaser’s sole and exclusive remedy for breach of warranty

shall be such replacement or credit.

A claim of defect in materials or workmanship in any Products shall be allowed only when it is submitted in writing within one

month after discovery of the defect or after the time the defect should reasonably have been discovered and in any event, within

(12) months after the delivery of the Products to the purchaser. This warranty does not apply to perishable items, such as seals,

wipers, fuses, filters, etc. No such claim shall be allowed in respect of products which have been neglected or improperly

stored, transported, handled, installed, connected, operated, used or maintained. In the event of unauthorized modification of

the Products including, where products, parts or attachments for use in connection with the Products are available from

Henkel, the use of products, parts or attachments which are not manufactured by Henkel, no claim shall be allowed.

No Products shall be returned to Henkel for any reason without prior written approval from Henkel. Products shall be returned

freight prepaid, in accordance with instructions from Henkel.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT WHICH HAS BEEN ALTERED, MISUSED, NEGLECTED, OR DAMAGED

BY ACCIDENT, OR IF THE SYSTEM WAS USED TO DISPENSE ANY LIQUID MATERIAL OTHER THAN HENKEL PRODUCTS.

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN THIS SECTION, HENKEL MAKES NO WARRANTY OF ANY KIND

WHATSOEVER, EXPRESS OR IMPLIED, WITH RESPECT TO THE PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND OTHER WARRANTIES OF WHAT-

EVER KIND (INCLUDING AGAINST PATENT OR TRADEMARK INFRINGEMENT) ARE HEREBY DISCLAIMED BY HENKEL AND

WAIVED BY THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF LIABILITY FOR HENKEL TO THE PURCHASER IN CONTRACT, IN TORT

OR OTHERWISE IN THE EVENT OF DEFECTIVE PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE FULLEST EXTENT POSSIBLE UNDER APPLICABLE LAWS, HENKEL

EXPRESSLY DISCLAIMS ANY LIABILITY WHATSOEVER FOR ANY DAMAGES INCURRED DIRECTLY OR INDIRECTLY IN

CONNECTION WITH THE SALE OR USE OF, OR OTHERWISE IN CONNECTION WITH, THE PRODUCTS, INCLUDING,

WITHOUT LIMITATION, LOSS OF PROFITS AND SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, WHETHER CAUSED

BY NEGLIGENCE FROM HENKEL OR OTHERWISE.

Henkel Corporation Henkel Canada Corporation Henkel Capital S.A. de C.V.

1001 Trout Brook Crossing 2225 Meadowpine Boulevard Calzada de la Viga s/n Fracc. Los Laureles

Rocky Hill, CT 06067-3910 Mississauga, Ontario L5N 7P2 Loc. Tulpetlac, C.P. 55090

Ecatepac de Morelos Edo. de México

Henkel Automotive Henkel Ltda.

Technology Center Rua Karl Huller, 136 - Jd. www.loctite com

2455 Featherstone Road Canhema 09941-410

Auburn Hills, Michigan 48326 Diadema/SP, Brazil

Loctite is a registered trademark of Henkel Corporation, U.S.A . © Copyright 2004. Henkel Corporation. All rights reserved. Data

in this operation manual is subject to change without notice.

This manual suits for next models

9

Table of contents

Other Loctite Water Pump manuals