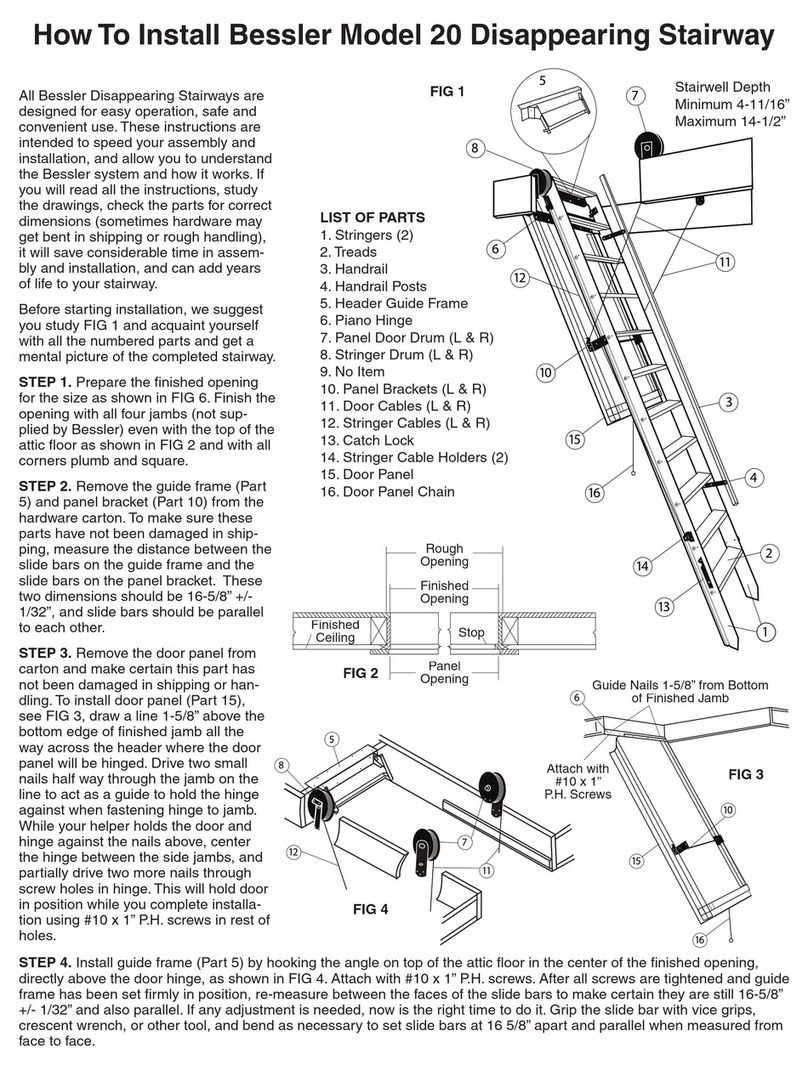

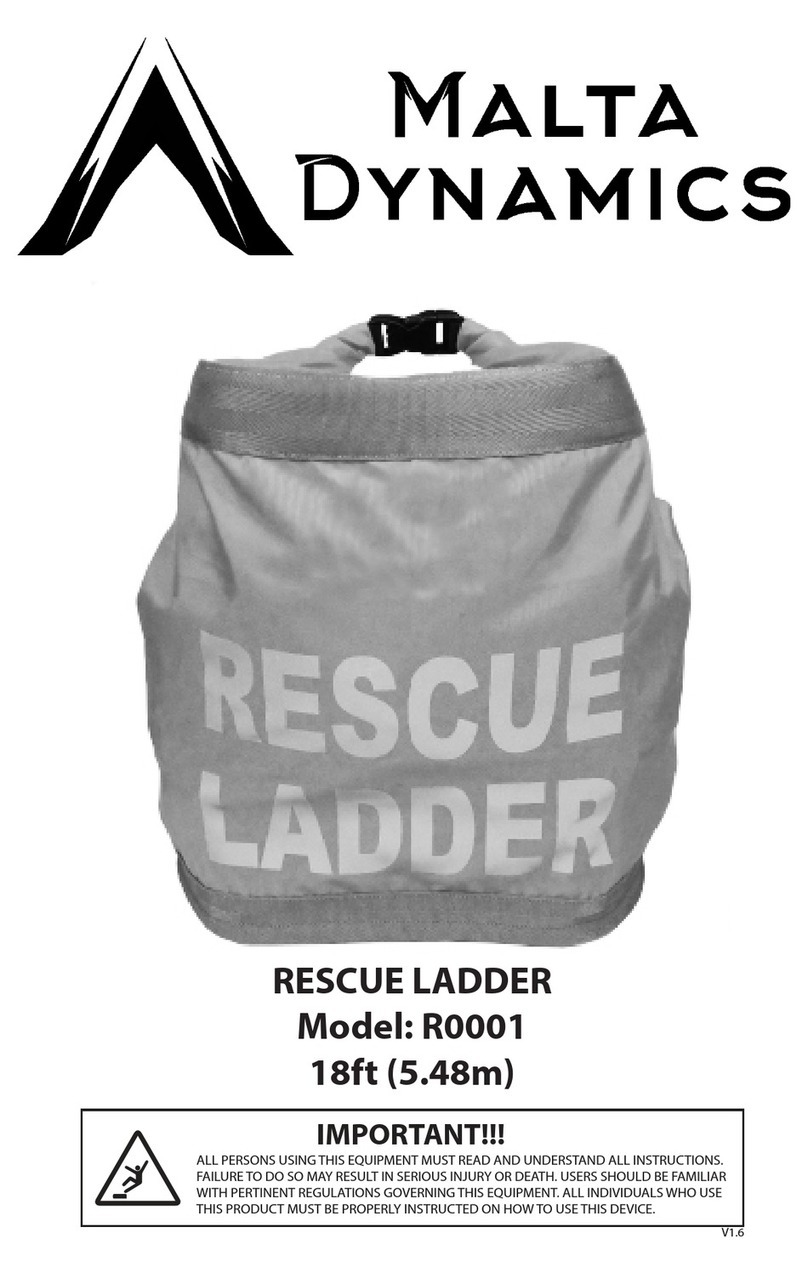

Step 22

Starting with all the cable wrapped on the drum,pull the cable parallel to the attic floor

and feed cable over pulley (No.9) and down to FORK on door guide frame (No.10).

Hook cable’s stop button under the fork. Repeat for left side. Refer to step 25 for final

adjustment of tension.

Step 23 - Attaching the Handrail

The handrail can be installed on either side of the ladder. The top post should be mounted plumb

to inside of the required string and resting on the second tread from the top using three No.10x 1½˝

CSKscrews.Attachhandrailabout100mmpasttoppostwithtwo1½"screws.Gototheotherendand

attach bottom post to inside of string with post resting on the bottom tread and plumb under the

handrail,attachwithtwo1½"screws.Positiontheotherpostsatequalintervalsonstairs. Thereare3

posts for sizes 1 - 4, and 4 posts for sizes 5 - 7. Handrails may be attached further down the stairs

depending on the customer's requirements. Make sure that the horns of the posts are covered by the

handrail. Always use the handrails when walking up and down the stairs.

HANDRAILS ARE FOR BALANCE ONLY AND NOT FOR LOAD BEARING.

Step 24

Raise the stairs as if to be stowed, but still open position on door panel. Make

sure that the catch lock (No.14) has engaged the catch pin by pulling the stairs

back about 45mm. DO NOT LET THE DOOR SLAM. Slamming the door may cause

damage to the string guide channel or tear the door guide frame (No.10)

from the door. NB: Refer to Step 25 for final adjustment of tension.

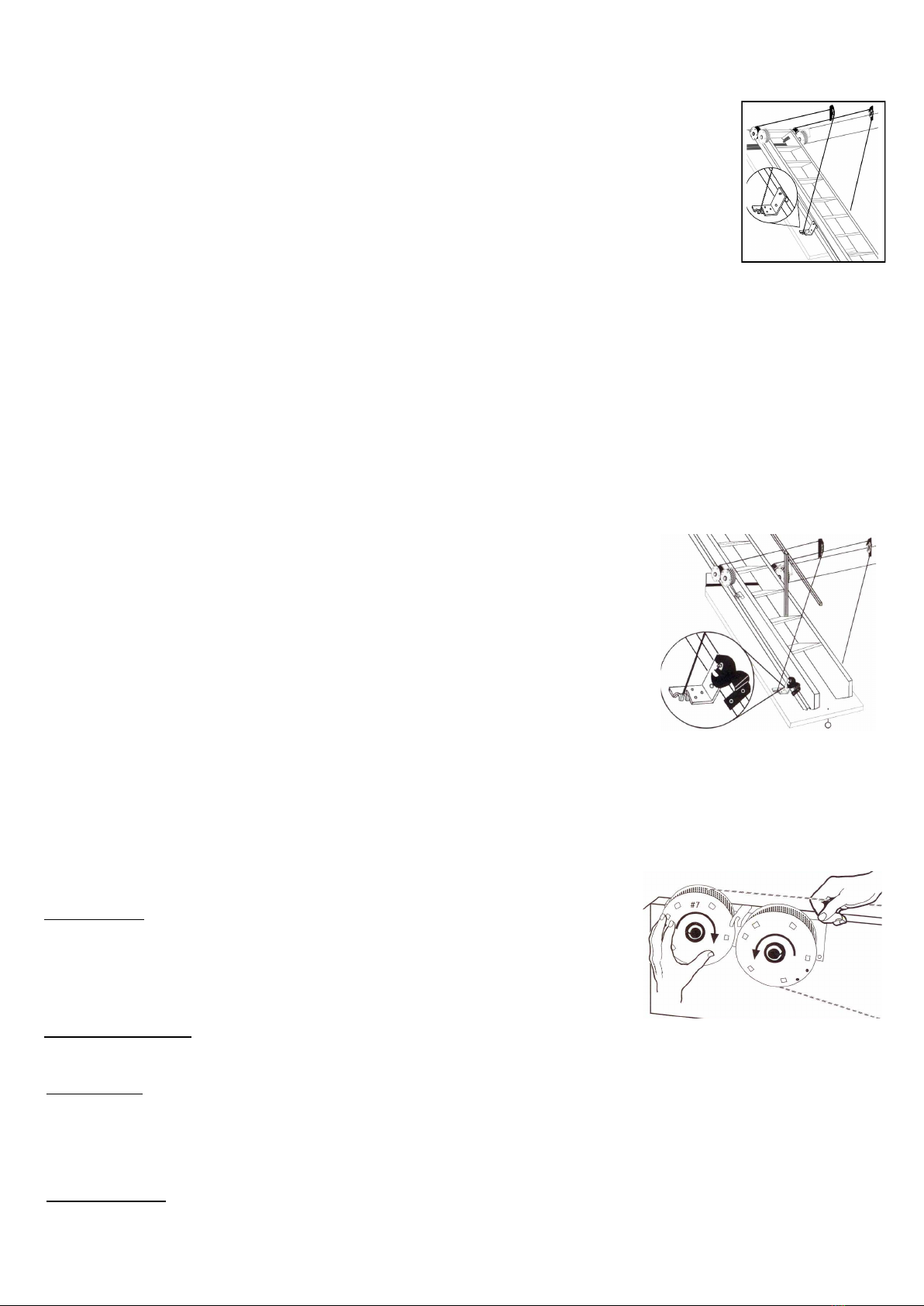

Step 25 : Adjusting Spring Drum Tension

Always work towards using the minimum amount of tension to do the job. On average, one complete

turn of the drum will add or reduce approximately 900g (2lbs) of lift.

Have enough tension for minimum force to slide the stairs up to the stored

position, but not so much that the stairs creep up when resting on the floor.

This could cause accidental tripping. Too little tension may allow the stairs

to feel heavy.

Door Panel Tension

The door should close very slowly without slamming, but with enough tension to hold the door against the stops.

by adding more turns of cable. Take the end of the cable loose from the cable holder and

slowly let it wrap up on the drum. While you still have a length of cable in your hand, hold the drum

firmly and wrap additional cable around the drum as needed. Return cable to holder.

Repeat for other side.

Reduce Tension by unwrapping additional cable. Take the end of the cable loose from the cable holder

Stair Tension

Add Tension

and slowly let it wrap up the drum. Hold the drum firmly and unwrap additional cable from the drum as

needed. Return cable to holder and repeat for other side.

WARNING

DO NOT LET CABLE SLIP FROM YOUR HAND AS SUDDEN RELEASE OF TENSION CAN

BREAK OR BACK-WIND THE SPRING AND CABLE TRAVEL MAY CAUSE PERSONAL INJURY

WARNING

DO NOT LET CABLE SLIP FROM YOUR HAND SINCE SUDDEN RELEASE OF TENSION CAN

BREAK OR BACK-WIND THE SPRING AND CABLE TRAVEL MAY CAUSE PERSONAL INJURY

8