Several options exist for hanging your artwork, but the general method utilizes picture hanging wire because it provides the greatest ease and flexibility with artwork

of any size. In recent years, strap hangers with D‑rings have grown in popularity over screweyes, because they lie flat against the back of the dust cover and won’t

scratch the wall.

Installing D-Rings

To position D‑Rings, measure about one‑third down from the top of the frame and mark the location. Do this on both sides. Nylon‑coated hanging wire comes in

three strengths: 19 lb., 25 lb. and 43 lb. Each strength is a measure of the weight‑bearing capacity of the wire. If the framed piece is too heavy for the wire, the wire

will unravel, pulling free of the hangers, regardless of the complexity of the knots used.

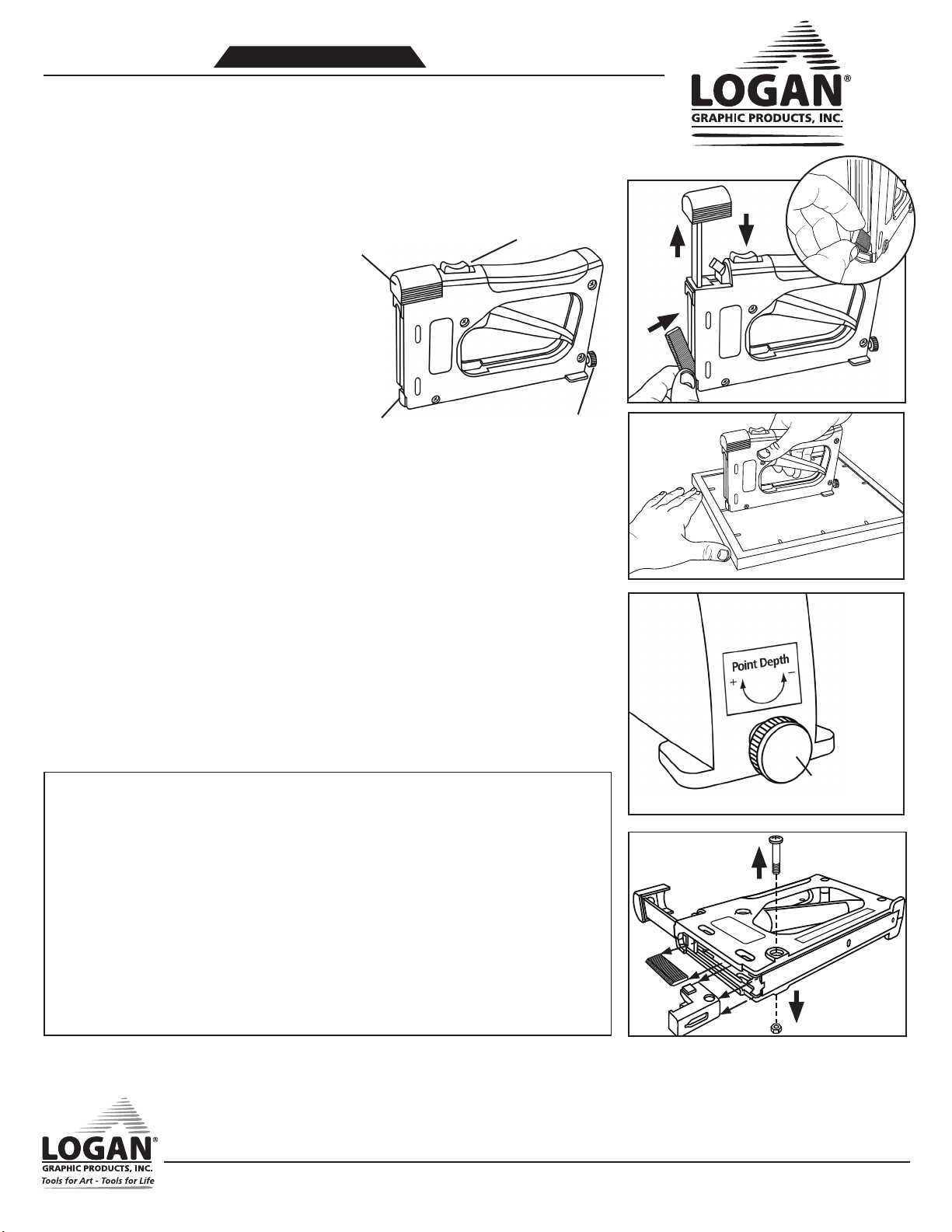

To attach D‑Rings to soft or medium wood frames,

make a pilot hole in the back of the frame with a

scratch awl. Turn the screw into the wood with a

screwdriver (Fig. 1). To attach a D‑Ring into hard‑

wood frames, drill a hole with a power drill and attach

the screw with a power screwdriver (Fig. 2).

Fig.1

Fig.2

Installing Wire

To install the wire, insert one end

through the D‑Ring allowing 3‑5 inches

of wire to feed through, twist it around

itself and loop it through the D‑Ring

one more time. Pull tight and then coil

the excess around itself keeping the coil

tight and cutting away any excess after

finishing. (Fig. 3)

Stretch the wire across through the other

D‑Ring allowing 3‑5 inches of excess, use

a finger to pull up slightly in the center of the wire to create some slack in

the middle of the wire and repeat the tying and coiling process. (Fig. 4)

Attaching Bumper Pads

For a nice finishing touch, attach self‑adhesive bumper pads to bottom corners on the back of your frame.

These will prevent the frame from scratching the wall, allow air circulation behind the frame to help prevent

any condensation and allow some light behind the frame to help prevent fading of wall paint color. (Fig. 5)

Fig.5

N1328 Rev 1 09/15

Logan Graphic Products Inc. 1100 Brown Street, Wauconda, IL 60084 1‑847‑526‑5515 1‑800‑331‑6232

www.logangraphic.com

Installing Hanging

Wire and Bumper Pads

PICTURE FRAMING

Instruction Sheet

Fig.3 Fig.4