3

Contents

1.0 Before the rst lift................................................................................................. 4

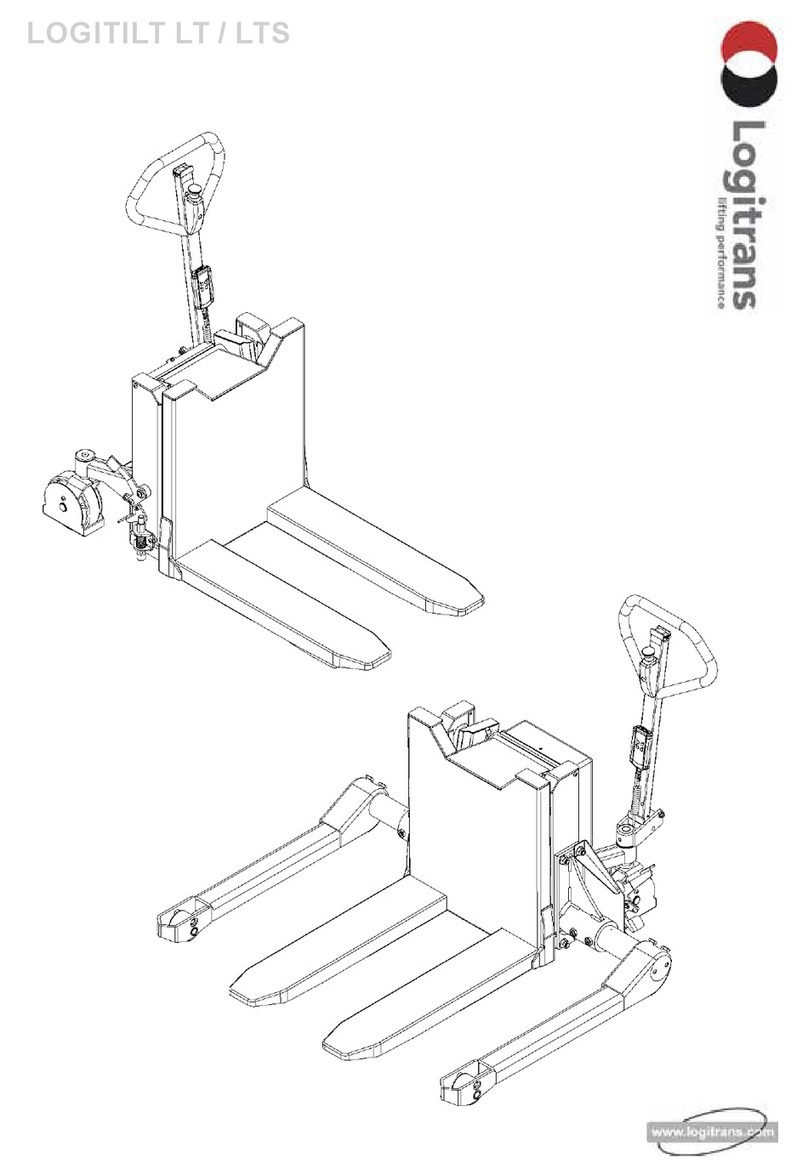

2.0 Functions and identications .......................................................................... 5

2.1Boxholder ........................................................................................................................... 6

2.2Boxholderwithclalmps....................................................................................................... 6

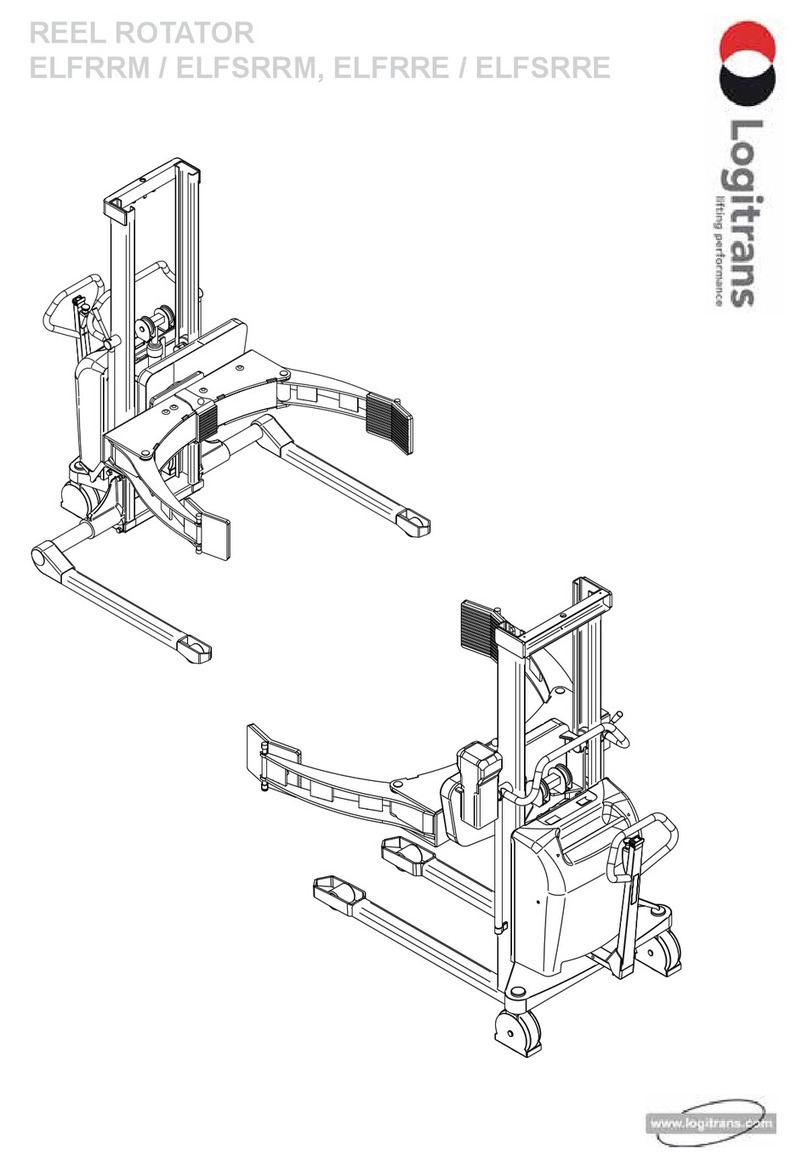

3.0 How to operate the Logex with Rotator ................................................. 7

3.1 Handling of pallets............................................................................................................... 7

3.2 Emergency stop................................................................................................................... 8

3.3 Handle functions.................................................................................................................. 9

3.4 Personal safety...................................................................................................................11

3.5UseoftheRotator ............................................................................................................. 12

3.6 Adjusting of stop ................................................................................................................ 13

3.7 Setting the speed............................................................................................................... 13

3.8Resetthesettings.............................................................................................................. 13

4.0 Optimum safety ......................................................................................................14

4.1 Avoid overloads ................................................................................................................. 15

4.2 Avoid offset loads .............................................................................................................. 16

4.3Rotationrange................................................................................................................... 17

4.4 Driving loaded.................................................................................................................... 19

4.5Rotationwithload.............................................................................................................. 19

5.0 There must be a current supply.................................................................. 20

5.1 Fuses - replacement.......................................................................................................... 20

5.2 Wiring connections ............................................................................................................ 20

6.0 Long live the Logiex with Rotator ............................................................ 21

6.1 Lubrication and hydraulic oil.............................................................................................. 21

6.2 Oil change ......................................................................................................................... 22

6.3 Forks adjustment............................................................................................................... 23

6.4 Adjustment of lifting chain.................................................................................................. 23

6.5 Hydraulic pump and gear motor ........................................................................................ 24

6.6 Cleaning ............................................................................................................................ 24

6.7 Adjustment of side play...................................................................................................... 25

7.0 Adjustment of the Rotator............................................................................... 26

7.1 Tensioning the chains ........................................................................................................ 26

7.2Adjustingtheswitch........................................................................................................... 27

7.3 Lubrication......................................................................................................................... 27

8.0 Fault location key................................................................................................. 28

9.0 Good service after purchase ......................................................................... 30

9.1 Ordering spare parts.......................................................................................................... 30

9.2Warranty/Compensation.................................................................................................... 30

9.3 Service and repair ............................................................................................................. 30

9.4 Warranty ............................................................................................................................ 30

9.5Liabilityexemption............................................................................................................. 30