Nibotechnics Autolift electric User manual

Installation instructions

doc.000 012018 2/7

Contents

SECTION

1. Parts referred to in these instructions .................................................................................. 2

2. Introduction ............................................................................................................................. 3

3. Installing your Autolift electric .............................................................................................. 4

Thank you for buying the Nibotechnics Autolift electric.

Symbols used adjacent to the text in these instructions:

Danger Means: electrical hazard warning, failure to understand and obey this warning

may result in electrical shock.

Warning Means: failure to understand and obey this warning may result in injury to you

or to others.

Caution Means: failure to follow these instructions may cause damage to all or parts of

the system or equipment

Note Means: this is important information for the correct use of this system

or equipment

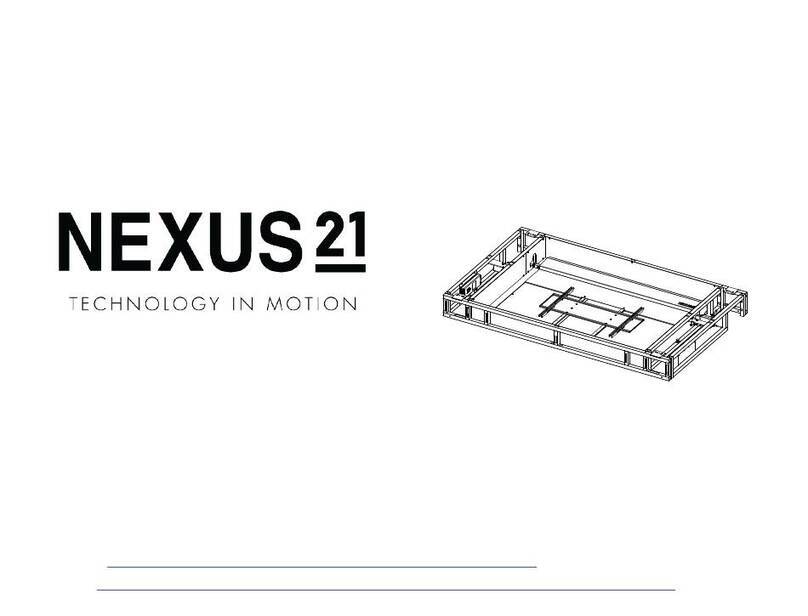

1. Parts referred to in these instructions

Fig. 1

doc.000 012018 3/7

2. Introduction

Before attempting to assemble your Nibotechnics Autolift electric thoroughly read and understand

these installation instructions.

Installation, examination and testing should be carried out by competent, fully trained personnel.

The simplest, safest and most effective way to install your product is to have it professionally installed

and load tested by a Nibotechnics approved engineer using Nibotechnics approved tools and test

equipment.

For information on installation, servicing and maintenance contracts please contact your local

Nibotechnics distributor.

Before installation, always thoroughly check the construction of the floor where the Autolift electric is to

be positioned. Also check that the flooring is of adequate strength, this will include, the material

specification and the soundness and/or deterioration of the material. If in any doubt as to the strength

of the floor or if the flooring type does not coincide with the categories mentioned below, then do not

install the Autolift electric but contact Nibotechnics nv or their approved distributor for more technical

information.

If possible, scan the floor with a metal detector in order to detect and avoid any underfloor services.

The Autolift electric is assembled as shown in Fig. 1. The chair may have to be attached to the chair

frame (by using the two screws provided).

The choice of position (upper or lower) for the chair and frame on the end of the curved support arm

will depend on the height of the bather using the equipment and the relative position of the bottom of

the bath to the level of the floor.

The lower position is preferred for persons of average height, (unless the bath height is a problem).

Shorter self operators should have the chair mounted in the lowest position.

If the operation of the equipment is to be carried out by a person other than the bather then this chair

position will not be of any consequence.

Ensure the chair frame securing bolts are well tightened before using the equipment.

Note:- Blanking plugs are provided to seal the un-used adjustment holes.

If the seat height needs to be raised or lowered more than the amount of adjustment on the standard

unit, then an extension plate can be supplied by Nibotechnics upon request.

The curved chair support arm in Fig. 1 may be mounted either for left or right handed operation,

simply by rotating the curved arm through 180º.

Care should be taken when lifting components to avoid injury.

Eye protection should be worn when drilling holes.

Some information contained in these instructions may become outdated, due to improvements made

to this product in the future. If you have any questions regarding these instructions or your hoist,

please contact Nibotechnics or their approved distributor.

Nibotechnics policy is one of continuous development, and therefore reserve the right to change

specifications without notice.

doc.000 012018 4/7

2. Installing your Autolift electric

Position the assembled unit adjacent to the bath and ensuring the chair is central and parallel to the

bath, lower the chair to within 25 mm (1") of the bottom and the end of the bath (see Fig. 2).

Using the handset, raise the chair up and fully rotate, ensuring there is adequate clearance for the

bather's legs. When the best position has been ascertained, mark the position of the base on the

floor, ensure the base does not move.

Remove the elevating unit from the base plate socket, by pressing in the plunger and pulling outwards

(see Fig. 3).

doc.000 012018 5/7

For Solid Concrete Floors only (see Fig. 4)

Using a 7 mm diameter masonry drill, drill through all the

holes in the base, then remove the base and increase each

hole to a diameter of 10 mm and to a depth of 85 mm.

Clear the dust from the holes using a vacuum cleaner and

insert the nylon plug until the top is in level with the floor.

(see Fig. 4)

For Wooden Floors only (see Fig. 5)

Only install the Autolift electric on to a wooden floor if the

floor boarding is 12 mm or more thick.

Using an 8 mm diameter drill, drill through the centre of all

the holes in the base.

Slight repositioning of the base may be necessary to avoid

joints or nails in the floorboards.

If the drill has to enter a joist then drill the hole to a depth of

70 mm. (see Fig.6)

Note: If the expansion anchor enters a joist, tightening

the screws will still ensure a secure fixing.

For increased security, the floorboards must be

screwed down to the joists in the vicinity of the

base with appropriate wood screws.

Using the fixing screw insert each nylon expansion anchor in

position.

Remove the fixing screws leaving the expansion anchor in

position.

Note: The anchor may have to be lightly tapped in to

'bed in' the small taper wedges on the top of the anchor.

doc.000 012018 6/7

If a wooden floor is fitted with a floor covering eg. hardboard,

tiles, carpet, plastic flooring etc, the expansion anchor should

be inserted so it's top face is flush with the original wooden

floor. (see Fig 7)

The resulting gap between the top of the

anchor/floorboarding and the finished floor level (tip surface

of floor covering) must be made up using the spacers

supplied.

Continuation (for concrete and wooden floors)

Position the base over the nylon plugs/expansion anchors and secure with the screws, as shown in

Figs. 4 and 5. Tighten the screws to form a rigid fixing.

Ensure all bolts and screws are fully

tightened on the unit and base.

Re-position the elevating unit and chair into the base plate socket.

Check that the base is securely fixed by putting your weight on the outside of the chair.

Rotate the chair and test in several positions.

With the elevating unit adjustment plunger inserted into the top hole of the base plate socket.

Position the chair over the bath and wind the handle until the chair is at its lowest position.

Support the jacking tube by holding where the curved chair support arm joins it (a second person may

be required for this operation) press in the adjustment plunger and slide the complete jacking unit

down in the base socket until the correct chair position has been attained (see Fig. 2). Release the

plunger into the next highest hole in the base socket.

When the Autolift electric has been installed, before it is used it must be thoroughly examined and load

the maximum safe working load (SWL) (shown on the rating label attached to the support arm).

When it has been inspected and load tested satisfactorily your Autolift electric is then ready for use.

Aftercare (see also Autolift electric operating instruction booklet)

UK HOISTS ONLY: A thorough examination of the Autolift electric, load testing of the base fixings at

the specified load (x 1,5 SWL) and checking for soundness and/or deterioration of the flooring material

in the vicinity of the Autolift electric must be carried out regularly every six months to conform to the

mandatory LOLER (Lifting Operations and Lifting Equipment Regulations 1998) examination and also

at the annual service.

NON UK HOISTS ONLY: A thorough examination of the Autolift electric, load testing of the base

fixings at the specified load (x 1,5 SWL) and checking for soundness and/or deterioration of the

flooring material in the vicinity of the Autolift electric must be carried out regularly every six months and

also at the annual service.

If the Autolift electric has to be removed for any reason then has to be re-installed in the same

position, the fixing holes and surrounding area should be carefully inspected. If the fixing holes are

enlarged or distorted or the surrounding area has deteriorated or been damaged do not install at the

same position until the fault/s has been rectified.

doc.000 012018 7/7

We strongly advise and warn that only Company Designated Parts, which are designed for the

purpose, should be used on equipment and other appliances supplied by the Company, to avoid

injuries attributable to the use of inadequate parts.

The Company's Conditions of sale make specific provision confirming no liability in such

circumstances.

Our policy is one of continuous development, and we therefore reserve the right to change

specifications without notice.

Produced by:

Nibotechnics nv

Heikant 5 |3930 Hamont-Achel |Belgium

T +32 (11) 80 20 40 |i[email protected]om |www.nibotechnics.com

This manual suits for next models

1

Table of contents