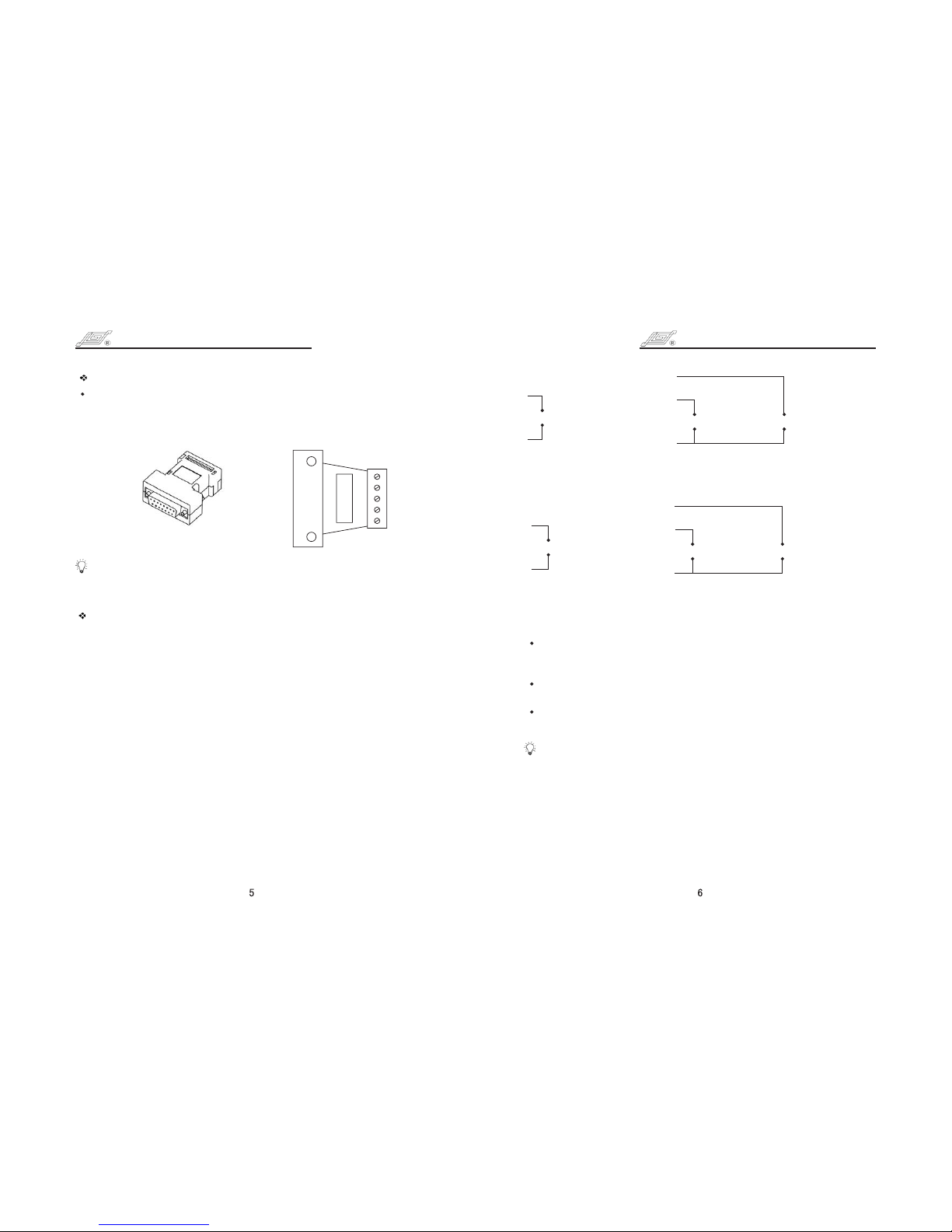

Terminal Definition of Standard External Control Module

4 20 mA, 0 - 5V, 0 10V

analog input control the

speed

--

0 5V, 0 10V, 4 20mA

External Control Input Module Connection Diagram

-- -

+

-

1

4

1# is analog input in 4 - 20 mA, 0 5 V, 0 10 V external control

modules. Control the speed of the pump.

2# is external control start/stop input. When connected to COM, the

pump runs; When connected to high level (5 10 V), the pump

stops.

3# is external control cw/ccw input. When connected to COM, the

pump rotates clockwise; When connected to high level, the pump

rotates counter clockwise.

4# is analog ground (AGND) in 4 20 mA, 0 5 V, 0 10 V external

control modules; 4# is pulse input in pulse input external control

modules. Control the speed of the pump. 10 KHz is corresponding

to the max.speed.

5# is the COM of external control direction and start/stop signal

input; It's also the COM of pulse signal input in pulse input

external control module.

--

-

---

CC/CCW Signal

(5V TTL)

Start/Stop Signal

(5V TTL)

+

-

3

5

+

-

2

0 10 kHz Pulse Signal Input Connection Diagram-

0 - 10 kHz pulse input

control the speed

+

-

4

5

Analog Control

Show as below for external control module. If you need external

control function you just insert the external control module to the

external control interface which is on the rear panel of the pump.

Connect the corresponding control signal wire.

Note:

Four kinds of standard external control module need to be ordered

separately according to special requirements.

External Control Model

5

4

3

2

1

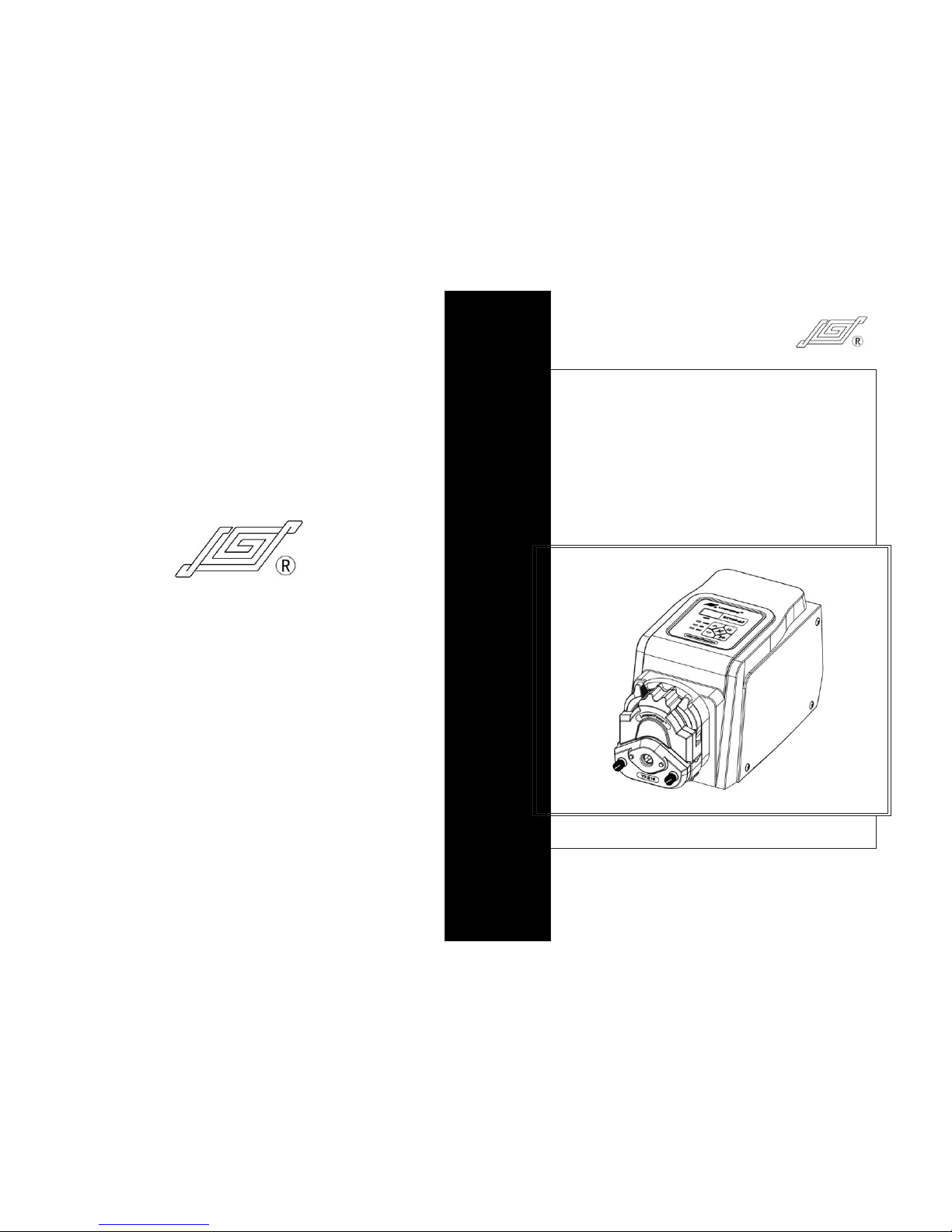

BT100-2J OPERATING MANUAL BT100-2J OPERATING MANUAL

CC/CCW Signal

(5V TTL)

Start/Stop Signal

(5V TTL)

+

-

3

5

+

-

2

Maintenance

When the pump is idle, we recommend you to release the tubing

from pressure. This helps to protect the tubing from unnecessary

strain and prolongs its service life

Keep rollers clean and dry. This will prolong the service lives of

tubing and pump head.

The surface of drive and the pump head are not organic solvent

and aggressive liquids resistant. Please pay attention when using.

Note:

If a trouble happens, please contact us or our dealers.

Warranty

The warranty period for this product is one year. If repair or

adjustment is necessary within the warranty period, the problem

will be corrected at no charge if it is not due to misuse or abuse on

your part, as determined by the manufacturer. Repair costs

outside the warranty period, or those resulting from product

misuse or abuse, may be invoiced to you.