15 16

Communication Function

WT600-1F can connect to the control computer (computer, PLC, SCM) through

RS485 serial communication interface. Max. 30 pumps can be controlled by a

control computer.

1. The pump ID which connects to the control computer through RS485 serial

communication interface must be unique to prevent the communication

error.

2. Please contact Longer Company for communication protocol.

Maintenance

When the pump is idle, we recommend you to release the tubing from pressure.

This helps to protect the tubing from unnecessary strain and prolongs its

service life

Keep rollers clean and dry. This will prolong the service lives of tubing and

pump head.

The sur face of drive and the pump head are not organic solvent and aggressive

liquids resistant. Please pay attention when using.

If a trouble happens, please contact us or our dealers.

Warranty

The warranty period for this product is one year. If repair or adjustment is

necessary within the warranty period, the problem will be corrected at no

charge if it is not due to misuse or abuse on your par t, as determined by the

manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

Technical Specifications

Functions

Acceptable Pump Head: YZ1515X, YZ2515X, YZII15, YZII25, DG15-24, KZ25, BZ25, DMD25

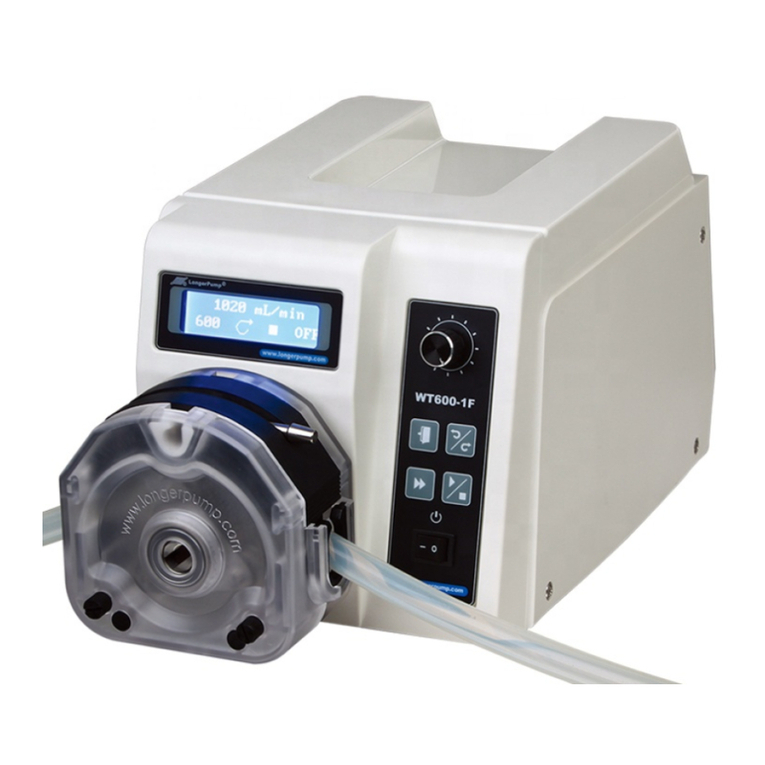

Operation Mode: Membrane keypad and Knob

Direction Control: CW and CCW, reversible

Prime: Full speed for fast filling and emptying

Back Suction: Prevent the liquid from dropping

Display: 128×32 graphic LCD displays all the information

External Control Input: Control Star t/Stop, direction and flow rates under flow rates mode

Footswitch: Control Star t/Stop of the pump

External Control Output: Output the signals of Star t/Stop, direction and speed

Communication: Communicate with control computer

Flowrate Function: Deliver fluid at set flow rates

Dispensing Function: Set dispensing volume, copy number and pause time, etc.

Memory Function: Store all the running information automatically

Calibration: Acquire higher accuracy

Cooling Mode: Heat-emitting fan

Specification

Speed: 10 - 600 rpm

Flow Rates: 0.7mL/min to 6000 mL/min

Dispensing Volume: 0.01mL to 9.99L

Copy Number: 0 to 9999 "0" means continuous running

Pause Time: 0.1s to 99.9min

Back Suction rpm: 0 to 9.9

External Control Input: Star t/Stop control, direction control, flow rates control (0 - 5V ,

0 - 10V , 4 - 20 mA , 0 - 10KHz optional )

External Control Output: Star t/Stop, direction, 0 - 10 kHz speed signal, OC gate output

Communication Interface: RS485

Applicable Power: AC 90 - 264V 50Hz/60Hz

Power Consumption: <150W

Operating Condition: Temperature 0 to 40 °C

Relative humidity < 80%

Dimension (L × W × H): 292.3 × 185 × 180.5 (mm)

Weight: 5.2 kg

IP Rating: IP 31

WT600-1F OPERATING MANUAL WT600-1F OPERATING MANUAL