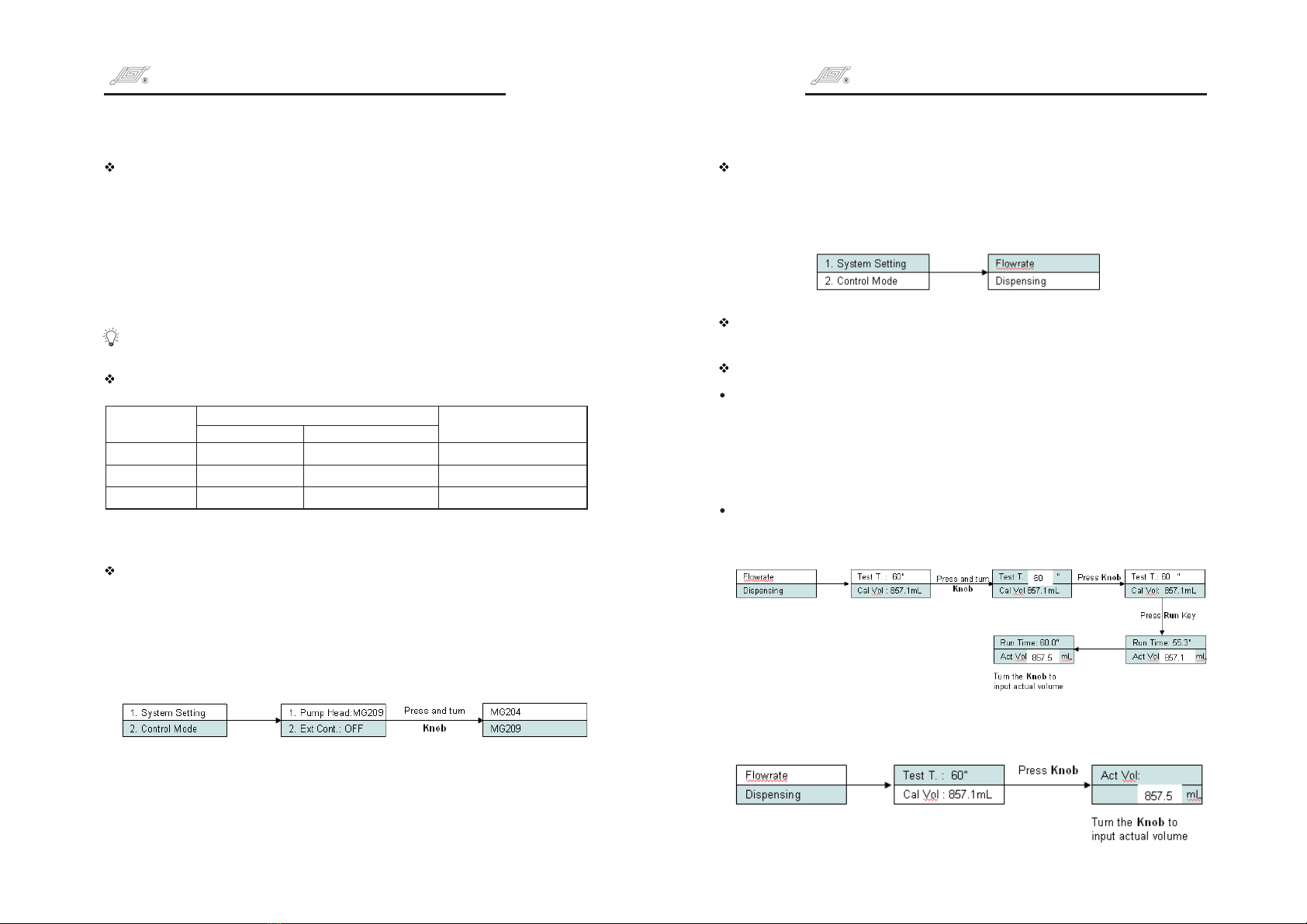

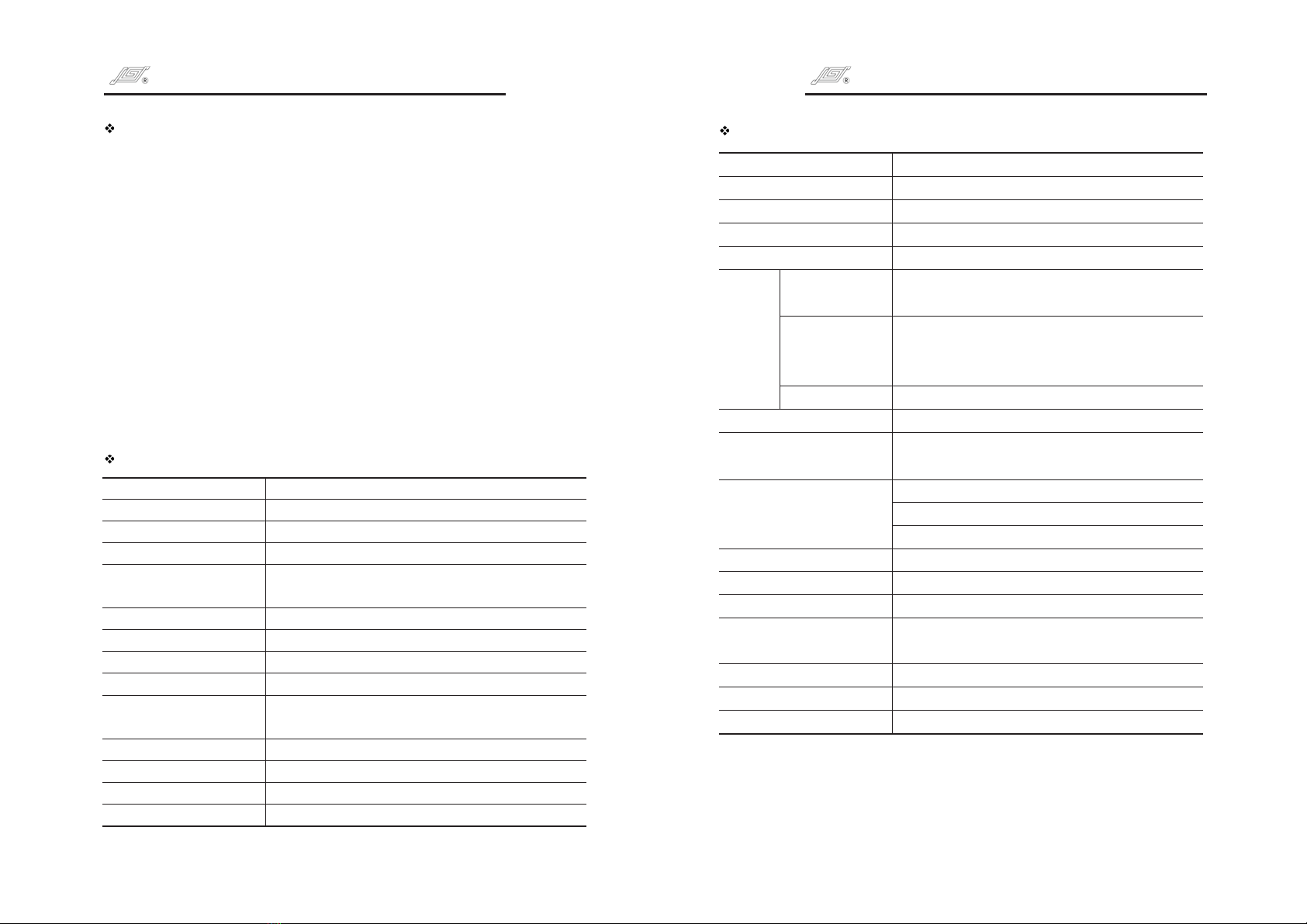

Terminal Definition of Standard External Control Module

1#

2#

3#

4#

5#

Analog input in 4 20 mA, 0.5 5 V, 1.0 10 V external control modules.

Control the speed of the pump. It is open in 1-10KHz. External control

module.

External control start/stop input. Open or connected to low level, the

pump runs; connected to high level, the pump stops.

Open

Analog ground (AGND) in 4 20 mA, 0.5 5 V, 1.0 10 V external control

modules; Pulse input in pulse input external control module, Control

the speed of the pump. 10 kHz is corresponding to the max. speed.

is the COM of external control start/stop signal input.

1

4

+

-

2

5

+

-

0.5 5V 1 10V 4 20mA,,~~ ~

Start/stop signal

4

5

+

-

2

5

+

-

1 10kHz

~

Start/stop signal

Analog signal input

control the speed

Footswitch has two kinds of working modes:

Press footswitch, the pump starts running; Press footswitch

again, the pump stops.

The pump runs as long as the footswitch is pressed.

Set footswitch

Press and turn to highlight the footswitch line. Press to

enter next interface, turn to select Trigger or Gated, press

for confirmation. Press not to store the selection and return

to previous menu.

The pump identifies the Longer Footswitch automatically. When the

pump connects the footswitch, the on operating panel

is invalid no matter the external control setting is on or off.

Trigger:

Gated:

Knob Knob

Knob Knob

Exit Key

Start/Stop Key

Footswitch Control

1.Enable the external control function.

2.These five Standard Analog Control Module need to be order

separately.

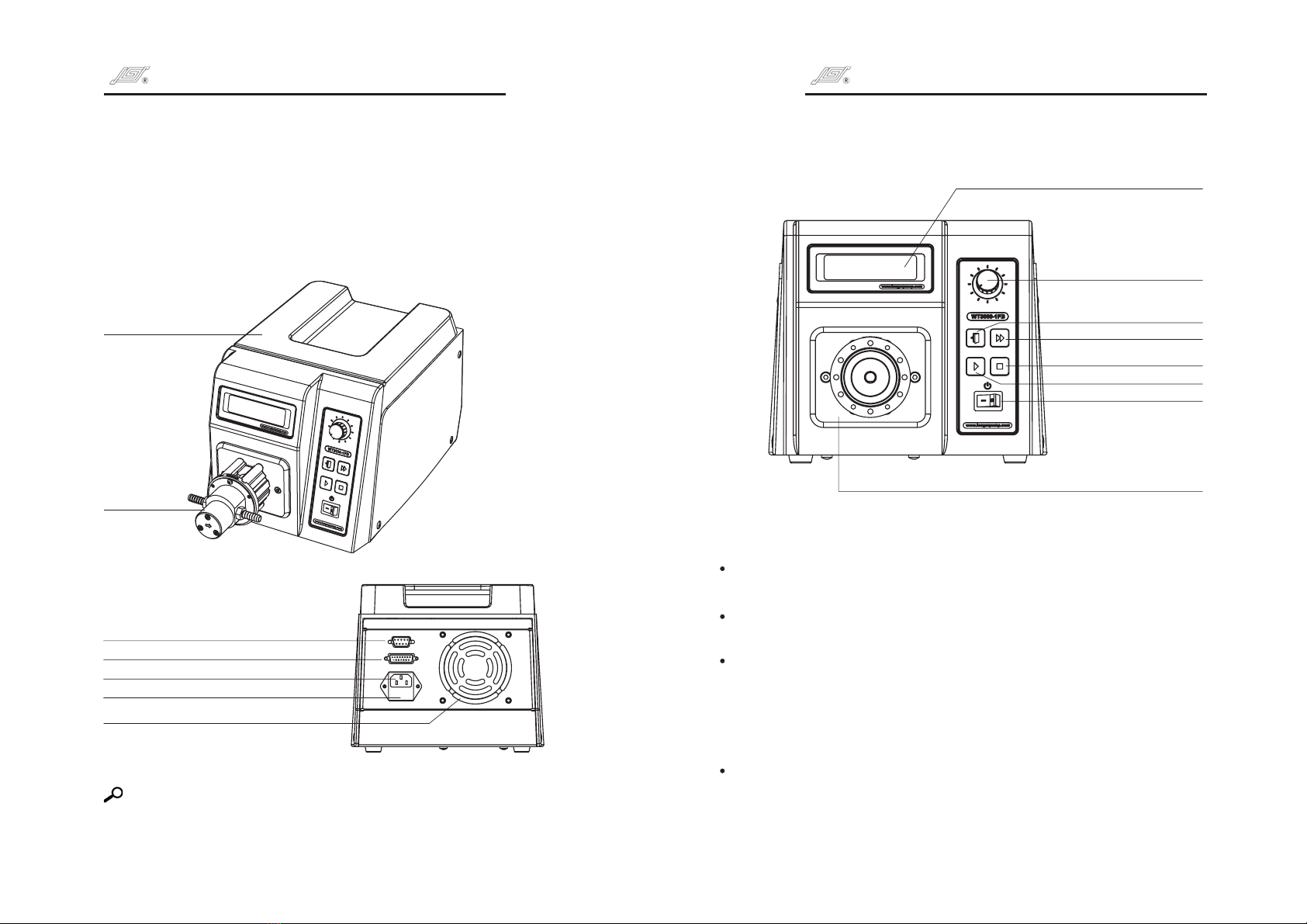

Communication Control Mode

The pump can connect to control computer (computer, PLC, SCM)

through RS485 serial communication module (shown as below). Please

contact Longer Company for communication protocol.

RS485 Communication Module Analog Signal Module

GND

B

A

5

4

3

2

1

Address setting

When control computer controls many pumps through RS485 interface, it

must identify each pump's I.D. This pump I.D. should be unique. It's the

identification of this pump. Maximum 30 pieces WT3000-1FB can be

controlled through RS485 at the same time.

Set the address

Press and turn to highlight the address line. Press again to

enter next interface, turn to select Pump I.D. number, press

for confirmation. Press not to store the selection and return to

previous menu.

Knob Knob

Knob Knob

Exit Key

11 12

Micro Gear Pump Drive Operating ManualMicro Gear Pump Drive Operating Manual