Longray TS35N User manual

Other Longray Insect Control Equipment manuals

Popular Insect Control Equipment manuals by other brands

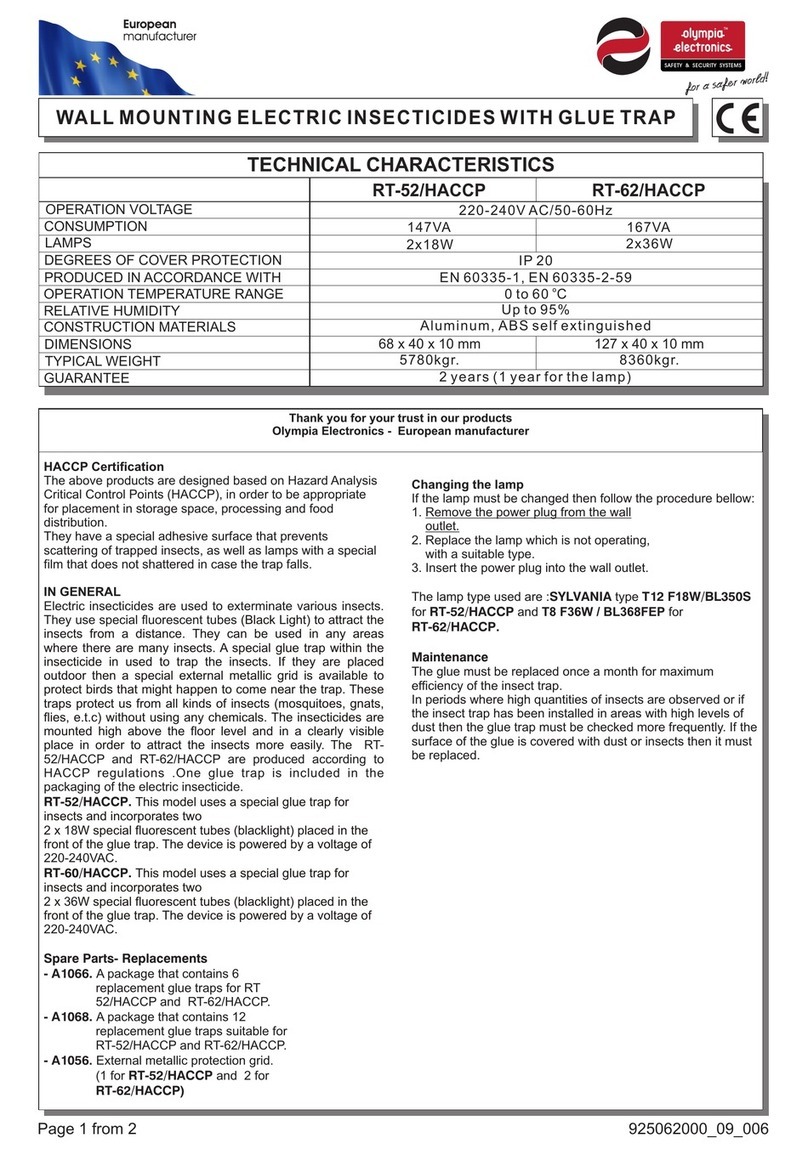

Olimpia electronics

Olimpia electronics RT-52/HACCP quick start guide

MistAway

MistAway GEN III Recommended Maintenance Procedures

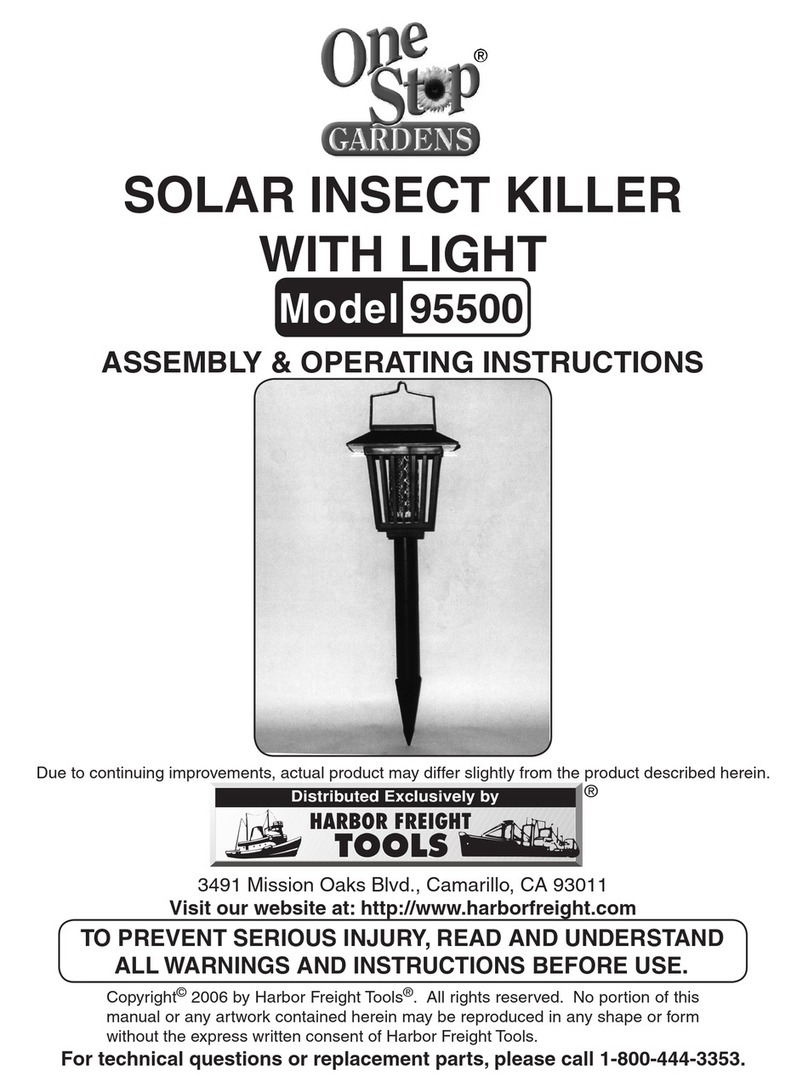

One Stop Gardens

One Stop Gardens SOLAR INSECT KILLER 95500 Assembly & operating instructions

Dynamic

Dynamic Dynatrap XL owner's manual

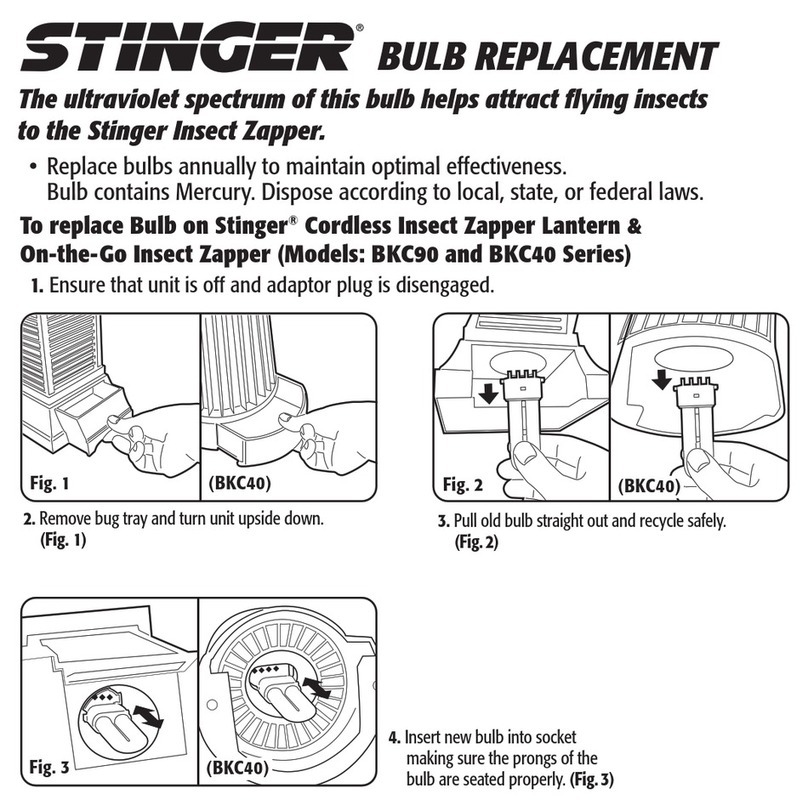

Stinger

Stinger BKC40 Series Replacement

Agrimate

Agrimate AF-4000NK-VM user manual