10

1010

10 / 18

heating switch is on, and there no water in hot tank, the heating element will be burnt.

• Check if the cooling switch is in switch off position, if not, please turn it off.

• Check if the socket this machine use is well grounded, make sure the socket is work properly.

(Note: this machine has high-power heating system, it must use three holes socket that can

load at least 10A current.)

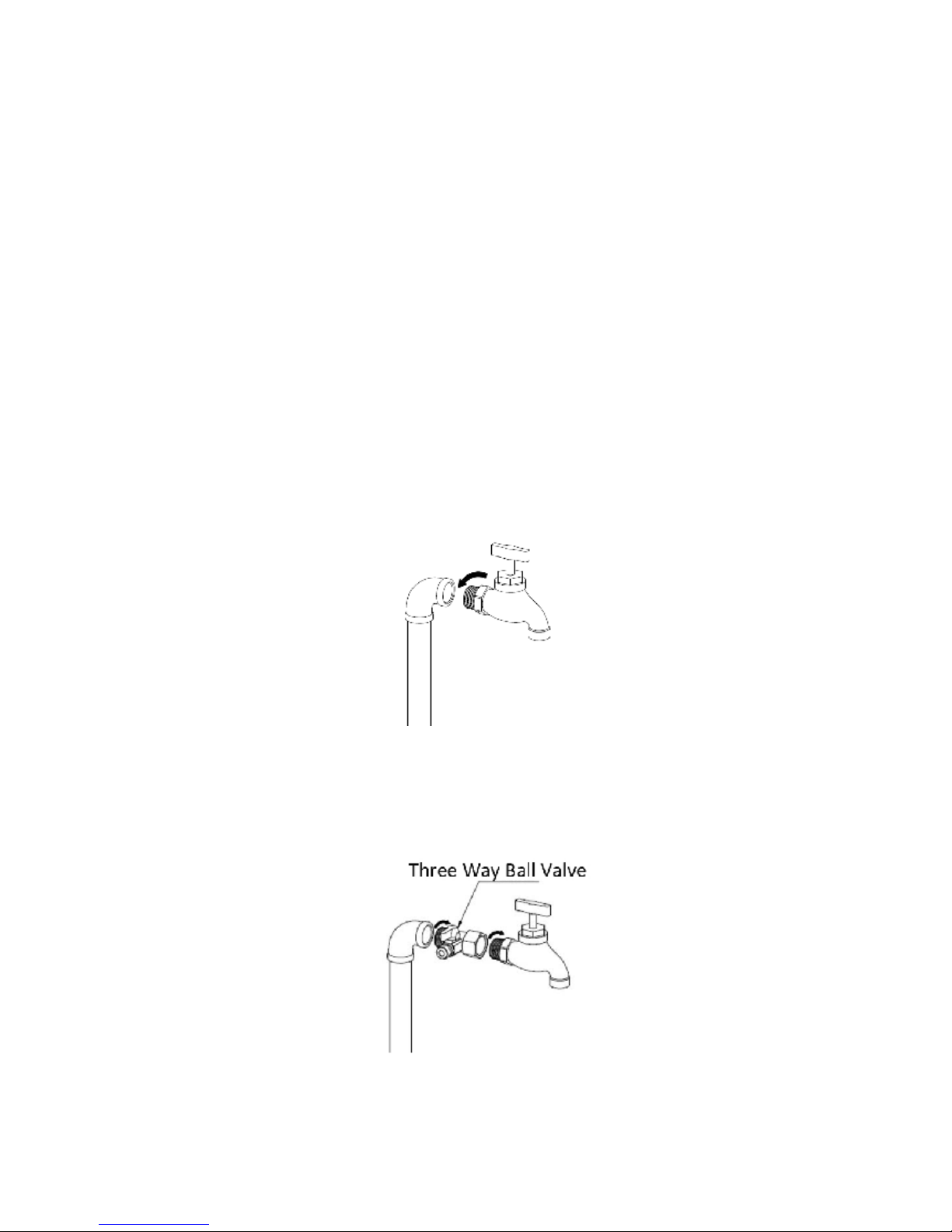

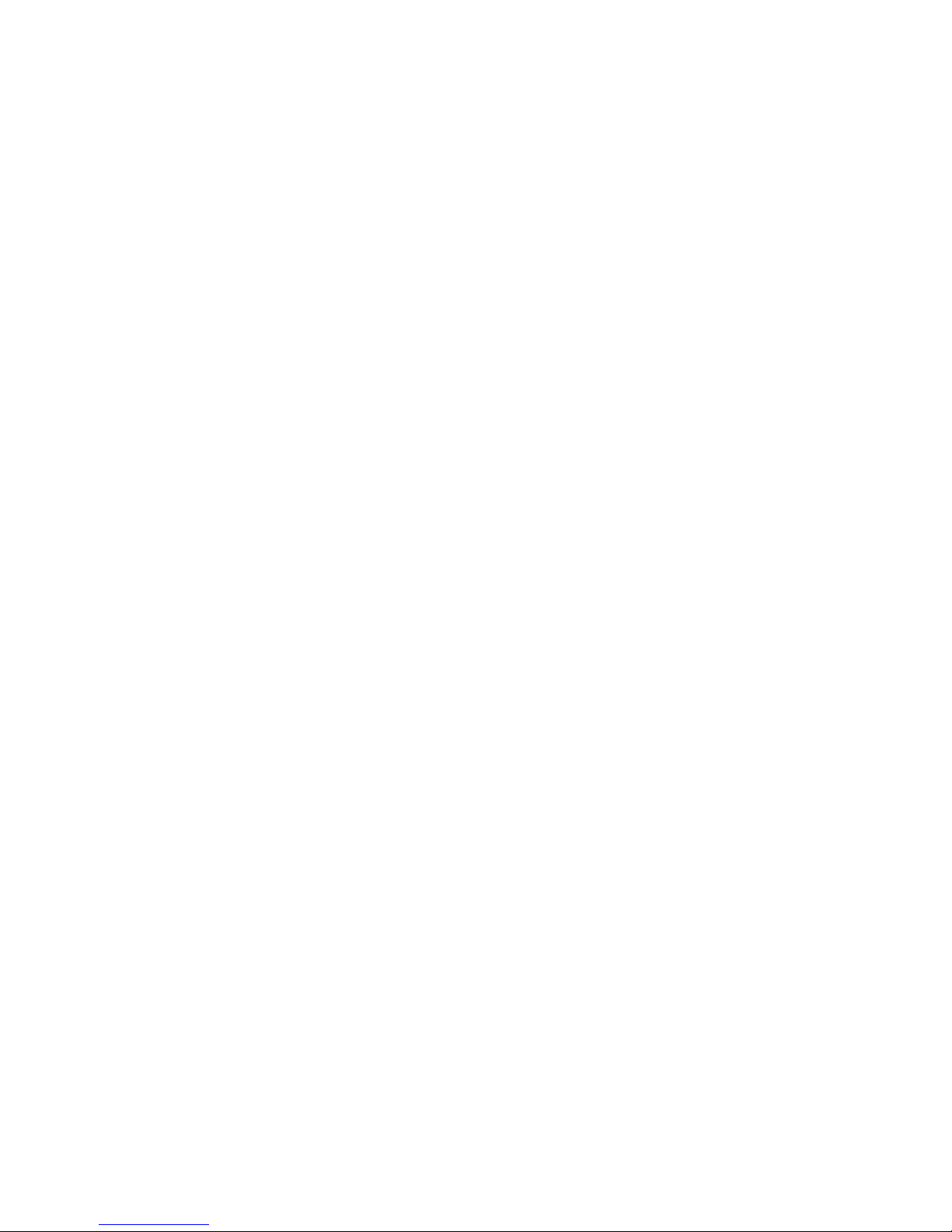

6.2. Connect to Water and Electricity Supply

Open the three way ball valve, machine connect with water supply.

Put the plug of machine into a three pin socket, machine connects with electricity supply.

7. Different Functional Systems.

7.1. Filtration System

7.1.1. ACF Filtration system / UF Filtration System

After connected with electricity supply, all the icons on the display panel shin for one

second, the indicator light ( see outlook instruction) become blue, the machine enter

working mode. Machine will detect there no water in tank and automatically enter

making water mode. The water making icon lights on, at the same time the water fill

into hot and cold tank, when all the tanks are full, the water making icon lights off. The

making water process finishes.

Note: This clause only applies to the machine with ACF filtration system or UF filtration

system.

7.1.2. RO Filtration System

After connected with electricity supply, all the icons on the display panel shin for one

second, the indicator light ( see outlook instruction) become blue, the machine enter

working mode. Machine will detect there no water in tank and RO system enter flashing

mode. After flash for 18 seconds, machine enter water making mode and the water

making icon lights on. At the same time the water fill into hot and cold tank, when all the

tanks are full, the water making icon lights off. The making water process finishes.

Note: This clause only applies to the machine with RO filtration system.

7.2. Hot Water System

After filling water process is finished, you can choose to turn on hot water function. Turn

on the heating switch at the back of machine, the heating icon lights on. And the heating

system is working, when the heating icon lights off, the heating process finishes.

Note: This clause only applies to the machine with heating system.

7.3. Cold Water System

After filling water process is finished, you can choose to turn on cold water function. Turn

on the cooling switch at the back of machine, the cooling icon lights on. And the cooling

system is working, when the cooling icon lights off, the cooling process finishes.