SYSTEM OPERATION

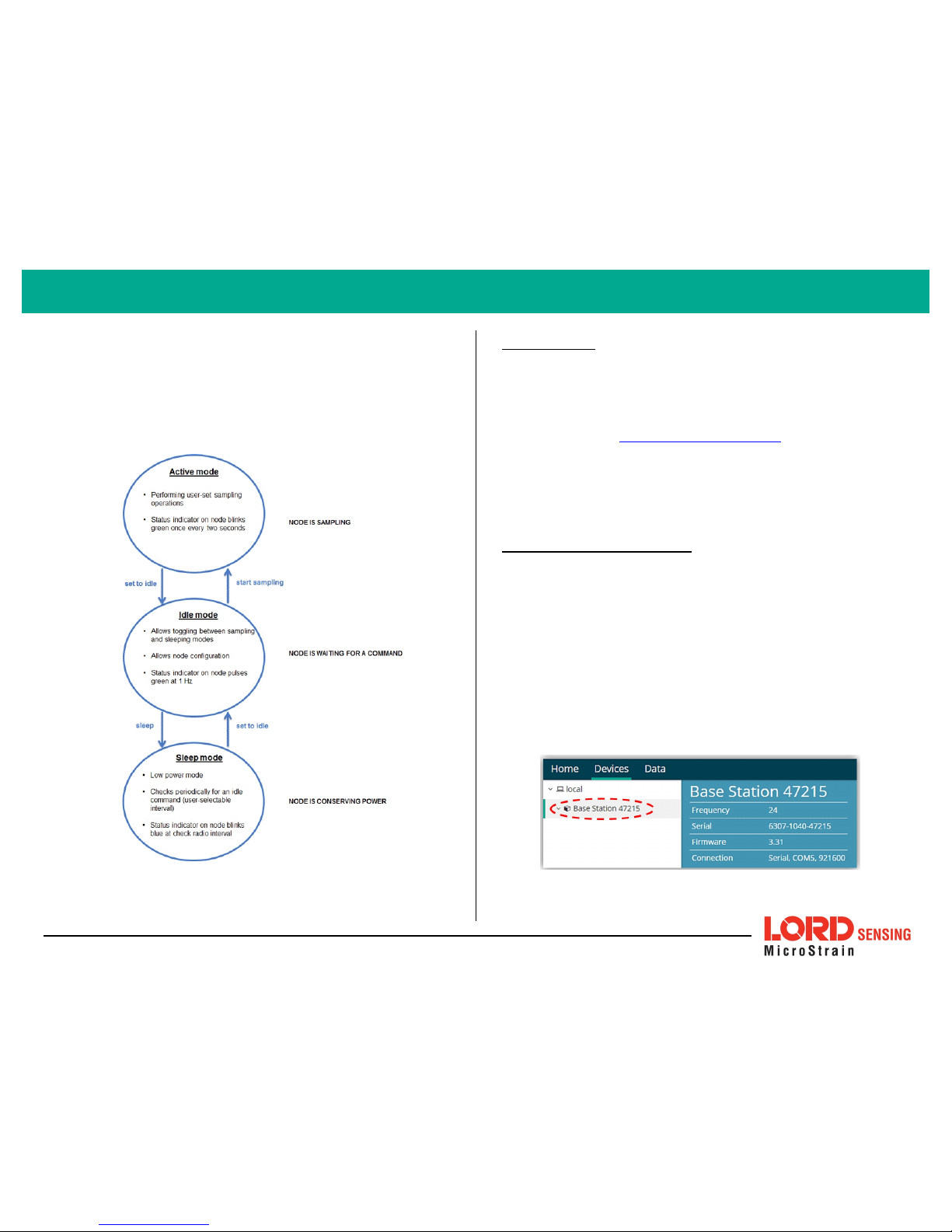

Sensor nodes have three operational modes:

active

,

sleep

, and

idle

. When the

node is sampling, it is in active mode. When sampling stops, the node is switched

into idle mode, which is used for configuring node settings, and allows toggling

between sampling and sleeping modes. The node will automatically go into the

ultra low-power sleep mode after a user-determined period of inactivity. The

node will not go into sleep mode while sampling.

Figure 1 - Node Operational Modes

1. Install Software

Install the SensorConnect software on the host computer before connecting any

hardware. The SensorCloud web platform is also available for data visualization

and analysis, and it is accessed by logging onto the SensorCloud website. The

SensorConnect software is available on the LORD Sensing website for free

download:

http://www.microstrain.com/software

SensorCloud is an optional data collection, visualization, analysis, and remote

management tool. It is based on cloud computing technology and is accessed

directly from a web connection. Automatic, real-time data collection is available

through Ethernet gateways, such as the WSDA- 1500. Data files can also be

uploaded. . For more information, see Connect toSensorCloud on page 1.

2. Establish Gateway Communication

Drivers for the USB gateways are included the SensorConnect software

installation. With the software installed, the USB gateway will be detected

automatically whenever the gateway is plugged in.

1. Power is applied to the gateway through the USB connection. Verify

the gateway status indicator is illuminated, showing the gateway is

connected and powered on.

2. Open the SensorConnect software.

3. The gateway should appear in the Controller window automatically

with a communication port assignment. If the gateway is not

automatically discovered, verify the port is active on the host

computer, and then remove and re-insert the USB connector.

Figure 2 - USB Gateway Communication

2

G-Link®-200 Wireless Accelerometer Node Quick Start Guide