Obere Schloßstr.131

73553 Alfdorf

07172 / 93730-0

Fax 07172 /93730-22

E-Mail: info@lorenz-sensors.com

Technical changes under reserve

Internet: www.lorenz-sensors.com

Contents

1Read First.............................................................................................................................................. 5

1.1 Safety and Caution Symbols.......................................................................................................... 5

1.2 Intended Use.................................................................................................................................. 5

1.3 Dangers.......................................................................................................................................... 5

1.3.1 Neglecting of Safety Notes ..................................................................................................... 5

1.3.2 Residual Dangers ................................................................................................................... 5

1.4 Reconstructions and Modifications ................................................................................................ 5

1.5 Personnel ....................................................................................................................................... 5

1.6 Warning Notes ............................................................................................................................... 6

2Term Definitions .................................................................................................................................... 6

2.1 Terms ............................................................................................................................................. 6

2.2 Definition of the Pictograms on the Torque Sensor ....................................................................... 6

3Product Description ............................................................................................................................... 6

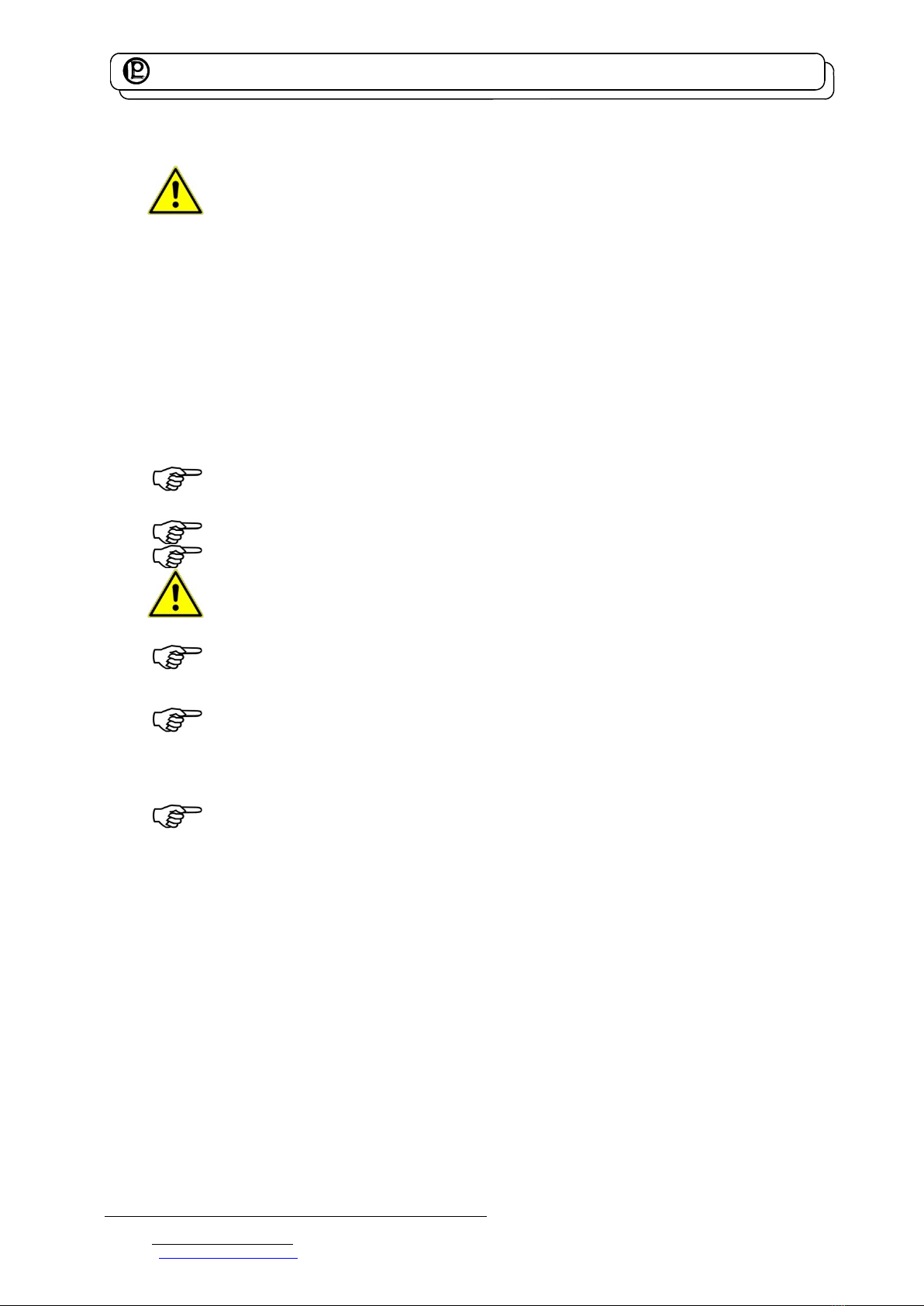

3.1 Mechanical Setup........................................................................................................................... 7

3.2 Electrical Setup .............................................................................................................................. 7

4Mechanical Assembly............................................................................................................................ 8

4.1 Rotor Assembly.............................................................................................................................. 8

4.2 Stator Assembly ............................................................................................................................. 9

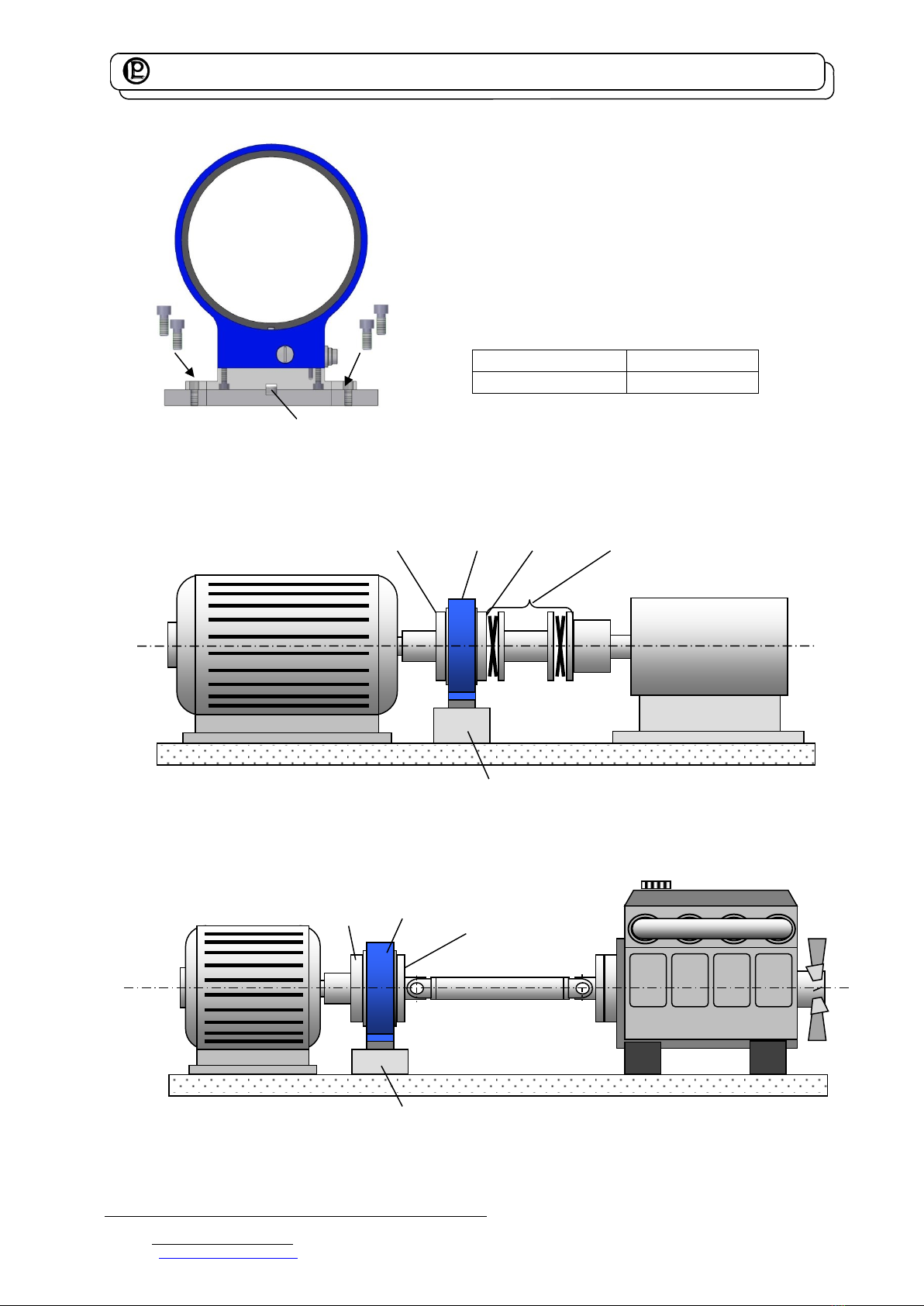

4.3 Basic Assembly.............................................................................................................................. 9

4.3.1 Assembly Example ................................................................................................................. 9

4.3.2 Using Center Bore ................................................................................................................ 10

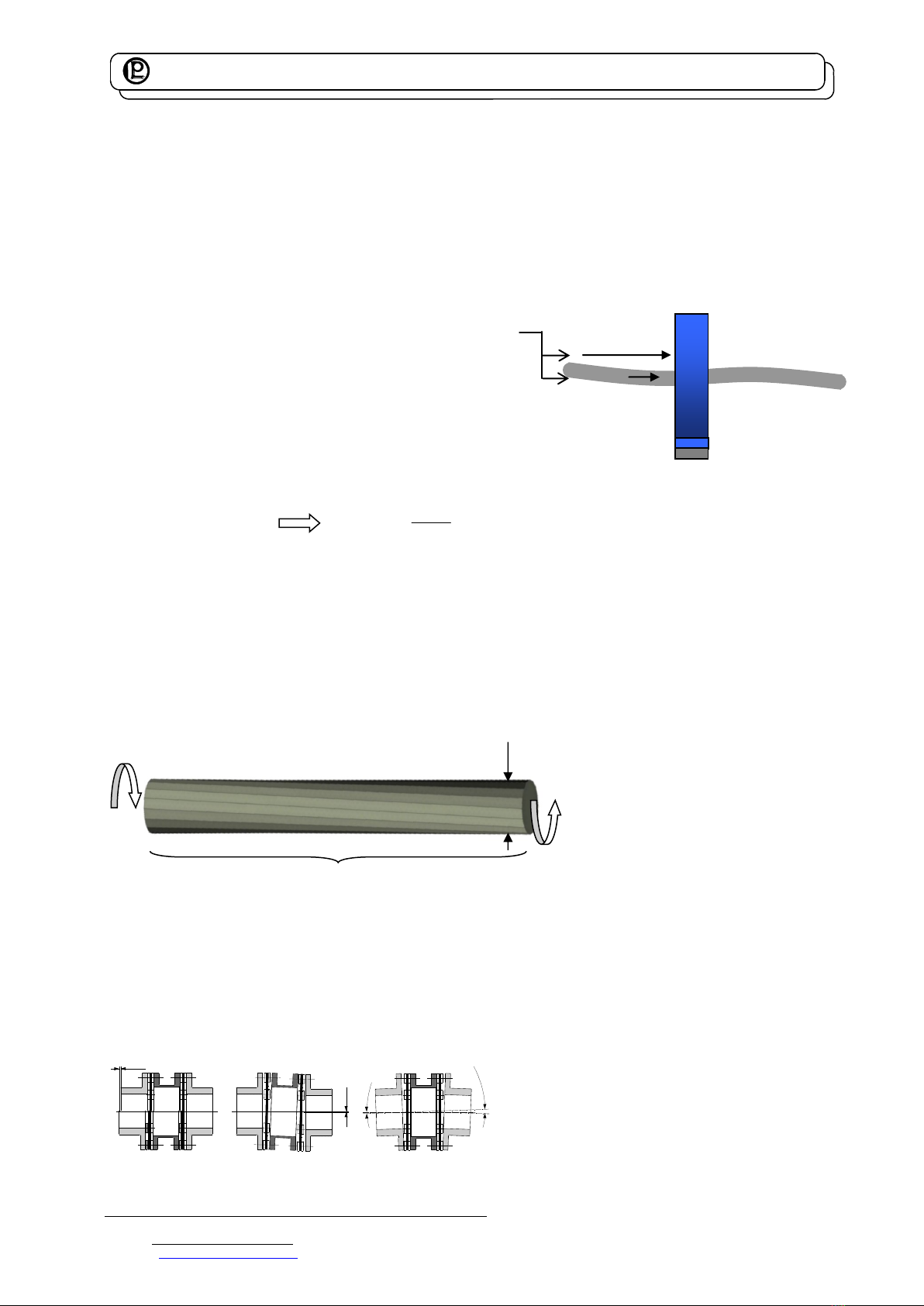

4.4 Couplings ..................................................................................................................................... 10

4.4.1 Alignment of the Measurement Arrangement....................................................................... 11

5Electrical Connection........................................................................................................................... 11

5.1 Pin Connection............................................................................................................................. 11

5.2 Cable............................................................................................................................................ 11

5.3 Shielding Connection ................................................................................................................... 11

5.4 Installation of Measuring Cables.................................................................................................. 11

5.5 Speed Sensor (Option) ................................................................................................................ 12

6Measuring............................................................................................................................................ 12

6.1 Engaging ...................................................................................................................................... 12

6.2 Direction of Torque....................................................................................................................... 12

6.3 Static / Quasi-Static Torques ....................................................................................................... 12

6.4 Dynamic Torques ......................................................................................................................... 12

6.4.1 General ................................................................................................................................. 12

6.4.2 Torsional Natural Resonances ............................................................................................. 12

6.4.3 Bending Natural Resonances ............................................................................................... 13

6.5 Speed Limits ................................................................................................................................ 13

6.5.1 Balancing .............................................................................................................................. 13

6.6 Disturbance Variables .................................................................................................................. 13

7Maintenance........................................................................................................................................ 13

7.1 Rotating Sensors.......................................................................................................................... 13

7.2 Trouble Shooting.......................................................................................................................... 14

8Transportation and Storage ................................................................................................................ 14

8.1 Transportation .............................................................................................................................. 14

8.2 Storage......................................................................................................................................... 14

9Disposal............................................................................................................................................... 15

10 Calibration........................................................................................................................................ 15

10.1 Proprietary Calibration.............................................................................................................. 15

10.2 DKD-Calibration........................................................................................................................ 15

10.3 Re-Calibration........................................................................................................................... 15

11 Data Sheet....................................................................................................................................... 15

12 Literature.......................................................................................................................................... 15