LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 • Phone: 425-493-1600

3/08 Page 3

Copyright © 2008 Lortone, Inc

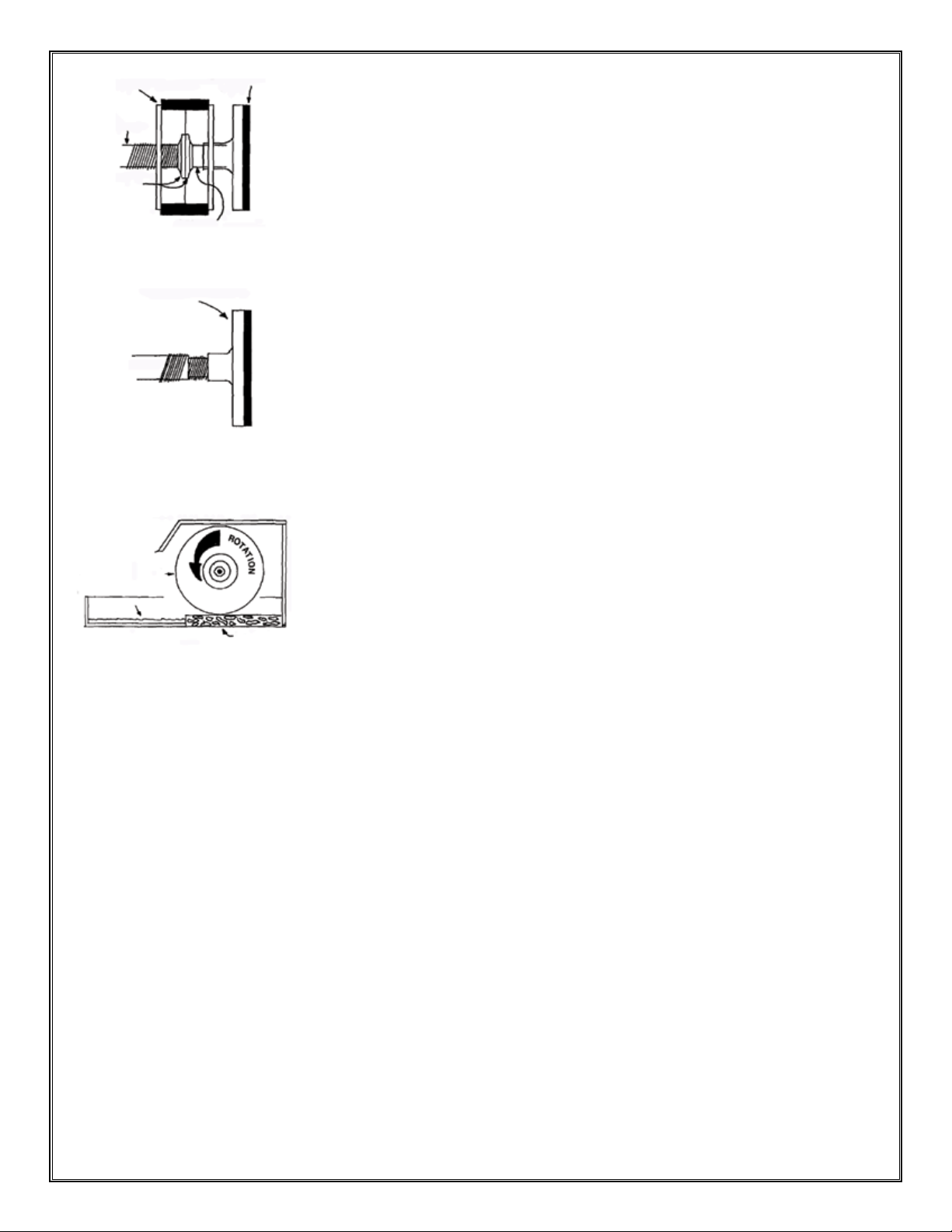

Polishing Head Installation

The LU6X-130 machine comes with a felt-faced polish head. Insert

the ¼-20 threaded end of the polish head into the end of the shaft

and tighten by turning the polish head clockwise. Avoid contaminating

the polish head during installation.

For versatility, additional polish heads can be purchased either with or

without the felt. Leather discs can be attached to the rubber face

polish-heads with feathering disc cement. If these heads are used for

sanding and are threaded 1/2” N.F.R.H., they may be installed on shaft

as show in Fig. 5. If they are used with a polishing pad, it is

recommended they be installed on the shaft by themselves (see Fig. 6)

to eliminate possibility of contamination.

Sawing

Pour coolant into saw case until 1/4” of blade is emerged in coolant

(see Fig. 7). We recommend using water with a rust preventative or

quality oil formulated for lapidary use. CAUTION: DO NOT use

Kerosene, Motor Oil, Transformer Oil, or Automobile Antifreeze.

Feed material into the blade with even pressure. Never force the

material into the diamond blade. The rate of feed should never be so

great that the blade slows down. For difcult to handle shapes, clamp

the material in the vise.

Grinding

It is important to remember that the saw is still running while the LU6X

is being used for grinding, sanding or polishing. To reduce coolant mist

from the saw when using the grinding side of the machine, place a

small household sponge on the trim table directly in front of the blade.

When you are ready to use the saw, remove the sponge.

The LU6X is designed to be operated with either a water drip system or

a recalculating system.

Water

Grinding Wheel

Sponge

Polishing Head

Shaft

Fig. 7

Fig. 6

Make sure 1/4” of

blade is submerged

in coolant

Shaft

Collars

Polishing

Head

Sanding

Drum

Spacer

Fig. 5

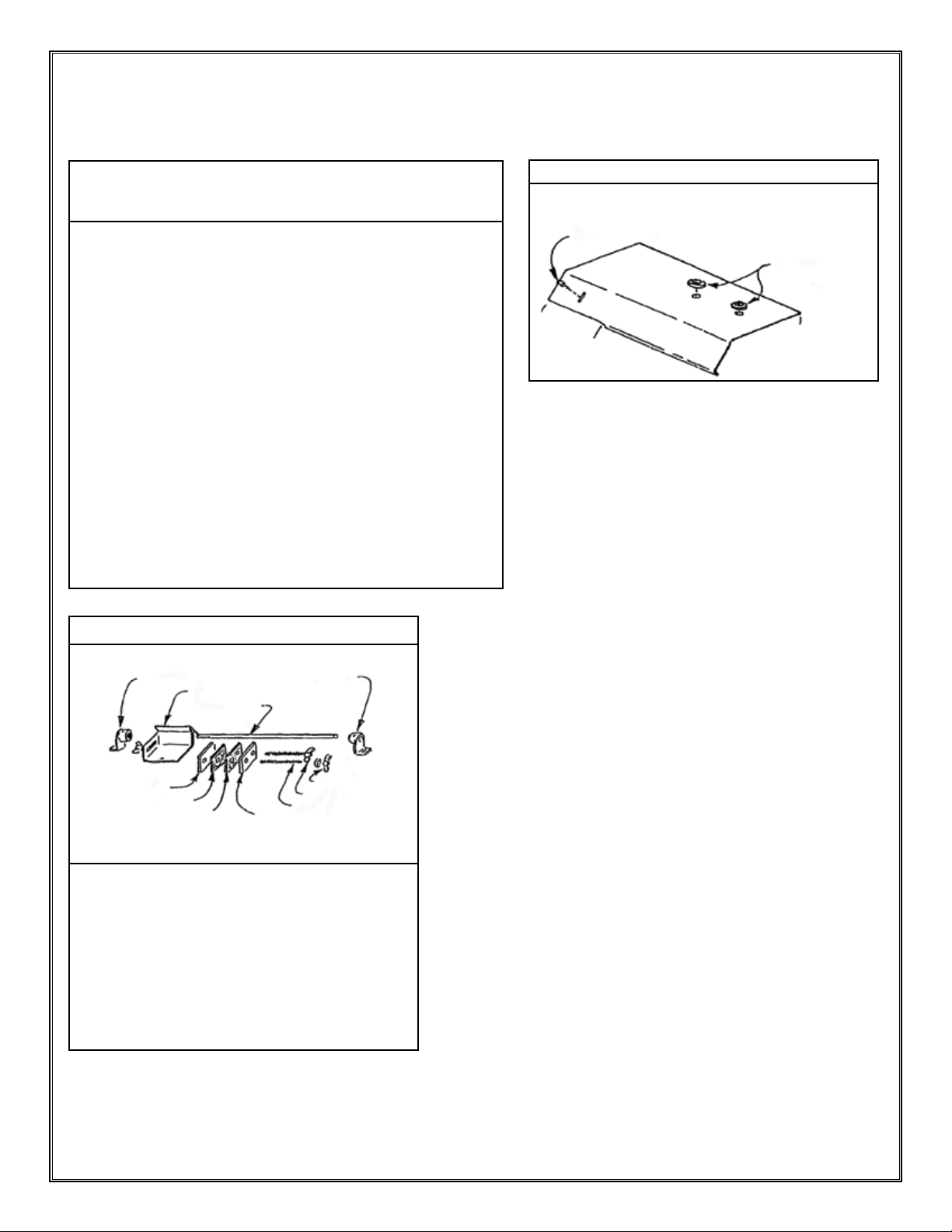

Periodic Maintenance

The bearings used in this arbor are sealed and lubricated for life. The nuts and collars are plated to

resist corrosion. The shaft is stainless steel which will also resist corrosion.

Helpful Hints

If it is inconvenient to hook up water valve and drain on grinding wheel side of unit, an acceptable

option can be to place a small amount of water in pan and carry it to the grinding wheel with the use

of a house hold sponge (see Fig.8).

The LU6X-130 is supplied with a 2-1/2” pulley & V-belt. A precision turned, ground, and polished shaft

is mated with sealed for life ball bearings for smooth, quiet operation. The point to remember is that

the basic machine is a smooth running unit. Vibrations and noise, which can occur during operation

of your machine, can often be traced back to the items being installed on the arbor shaft (grinding

wheels, sanding drums, polishing heads, etc.) not being trued and balanced.