OVERVIEW

Page 4

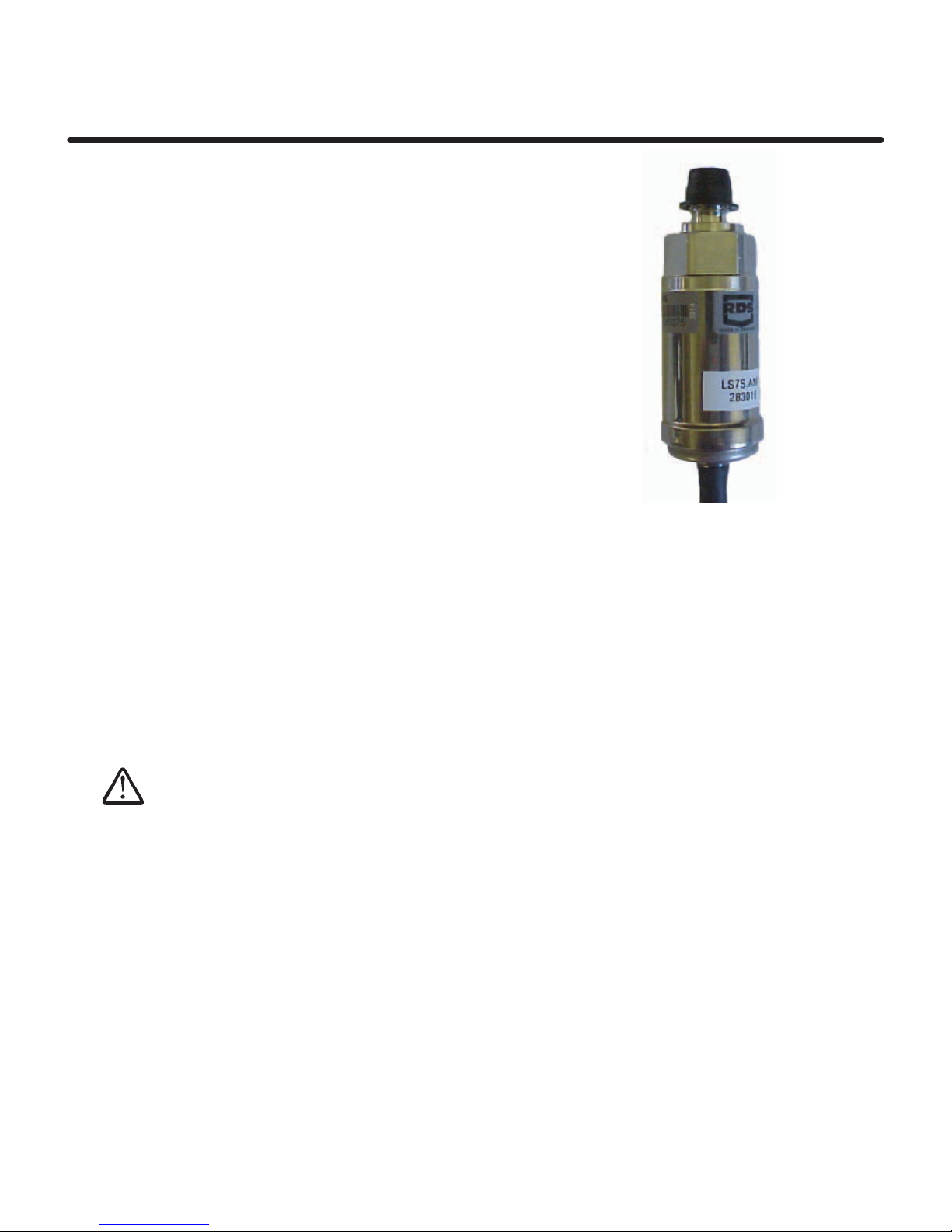

Load Sensor: This is either a 250 bar rated pressure sensor installed in the lift cylinder

hydraulic circuit, or in some instances a strain sensor mounted on the top side of the lift arm

(example: on certain telescopic handlers).

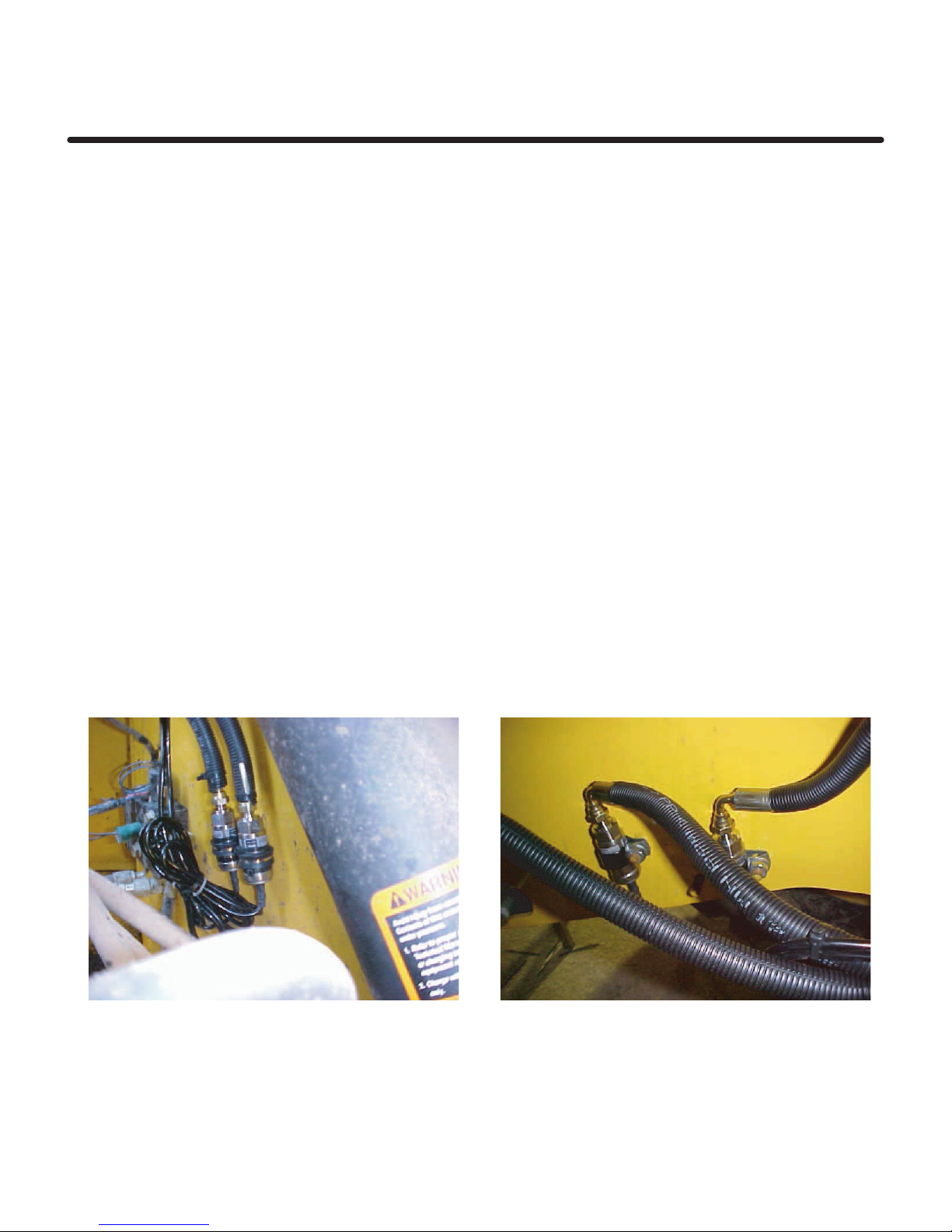

Reference/Direction Position Sensor: The pressure/strain must be measured

with the Lift arm in the same position each time. The reference/direction sensor is mounted near

the lift arm pivot point. It senses when the lift arm is in the correct weighing position, and if the

load is being lifted or lowered. The sensors are triggered by a magnet mounted on the side

of the lift arm.

Remote Enter button: This is mounted next to the lift lever and is used to record

the bucket weight, clear the channels and used in the zero bucket routine.

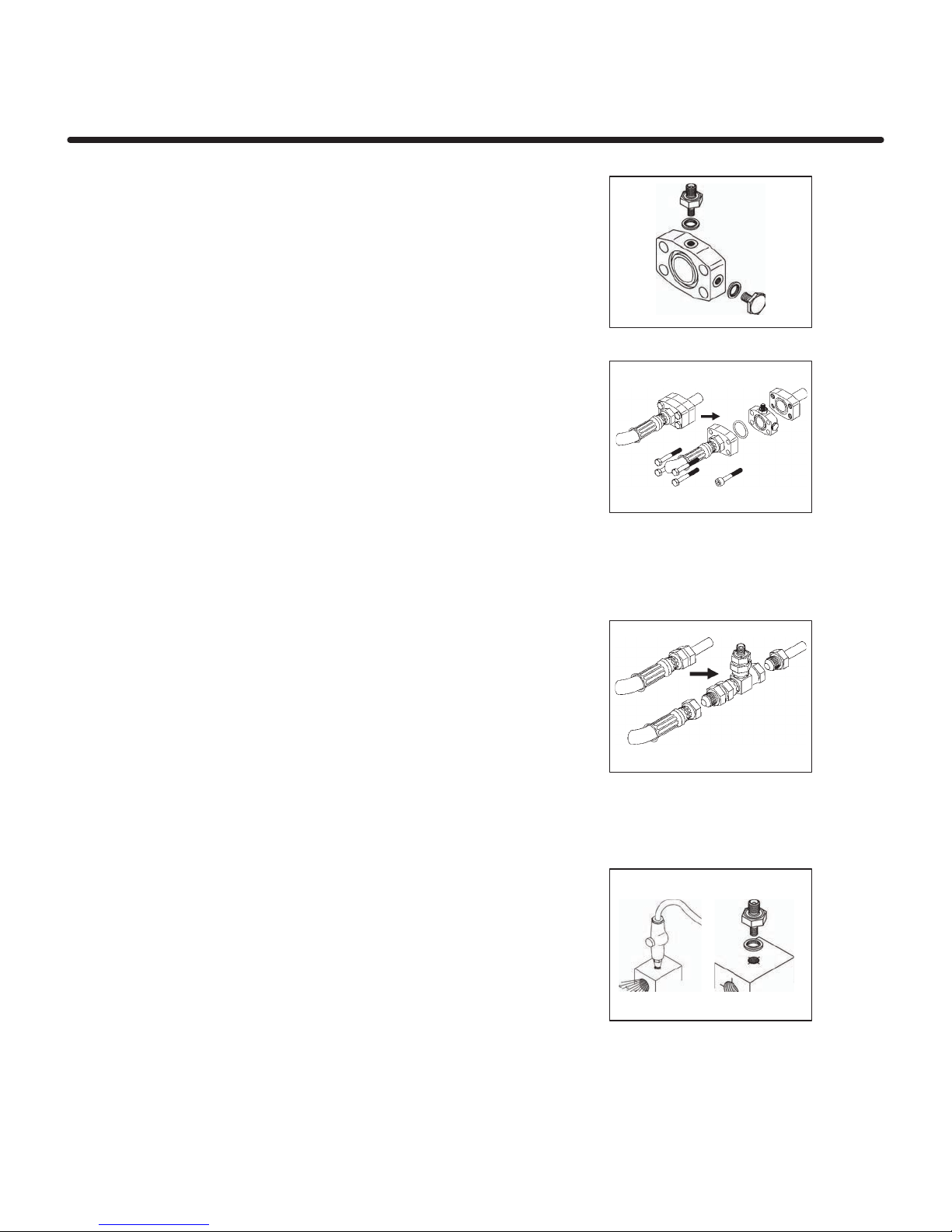

Head Unit and wiring: The head unit is supplied with a universal mounting bracket

assembly allowing it to be mounted in almost any configuration. A single multi-conductor lead

connected to a small Junction Box. Sensor and power connections are also made at the junction

box. The junction box has mounting holes if required.

The Weighlog 100 is intended for use on industrial and agricultural loaders; Such as Skid steers,

Small wheel loaders and some Telescopic Handlers.

It measures, displays and records the net weight lifted, based on the lift system hydraulic

pressure. Pressure sensing is problematic on certain types of equipment due to the design of the

hydraulic system. In these instances strain sensing technology may be used instead.

Overview

System Components

Important Safety Precautions !

In addition to observing site safety requirements, before working on the machine always:-

Make sure that the bucket is down on the ground and all pressure is released from the

hydraulic system, before loosening any hydraulic coupling or fitting.

To Prevent the machine from being accidentally started while working on it, Always

remove the ignition key.

Keep other persons in the vicinity of the machine fully aware of your intentions during

installation and initial calibration.