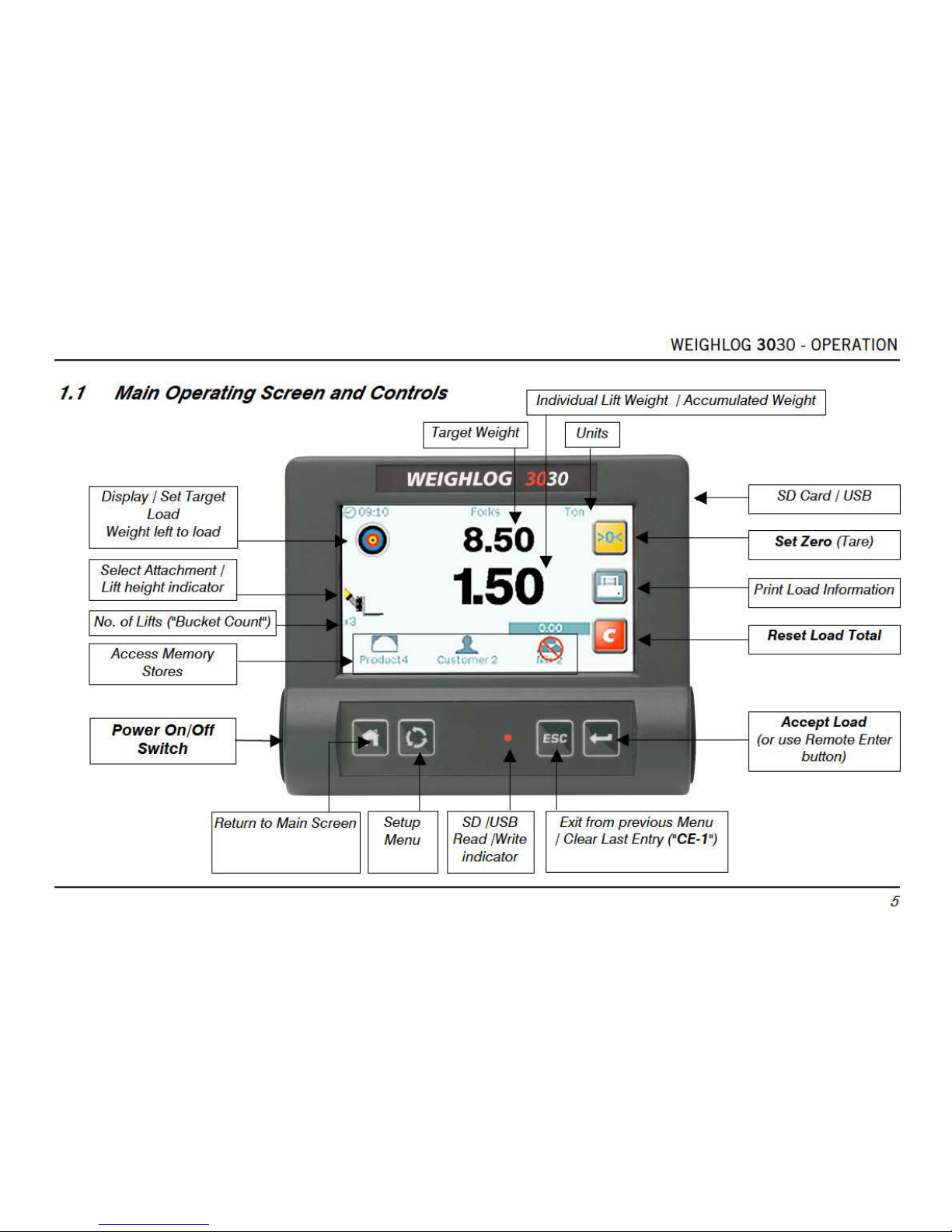

WEIGHLOG 3030 - OPERATION

2

3. Weighing _____________________________________________________________________________________________________ 17

3.1 Weighing Modes ................................................................................................................................................................ 17

3.2 Machine Requirements ...................................................................................................................................................... 17

3.3 Lifting Procedure................................................................................................................................................................ 18

3.4 Set Zero.............................................................................................................................................................................. 18

3.5 Dynamic Weighing ............................................................................................................................................................. 19

3.6 Static Weighing .................................................................................................................................................................. 20

3.7 Weighing without an "R/D" Sensor ..................................................................................................................................... 21

3.8 Weighing in Blend ("Mix") Mode ........................................................................................................................................ 22

3.8.1 Batch Mixing......................................................................................................................................................... 23

3.9 Clear Last Weight Entry ("CE-1")......................................................................................................................................... 24

3.10 Reset Load Total ................................................................................................................................................................ 24

3.11 Adjustment for Incorrect Weight Readings ("Nudge")........................................................................................................ 25

4. Printing and Data Transfer _____________________________________________________________________________________ 27

4.1 Printing ............................................................................................................................................................................... 27

4.1.1 Print Modes .......................................................................................................................................................... 27

4.1.2 Print ALL Product Memory Stores........................................................................................................................ 28

4.1.3 Print a single Product Memory Store ................................................................................................................... 28

4.1.4 Print ALL Customer Memory Stores..................................................................................................................... 29

4.1.5 Print a single Customer Memory Store ................................................................................................................ 29

4.1.6 Types of Printout .................................................................................................................................................. 30