.P.A.

24020 GORLE (BERGAMO) ITALI

FAX (International): +39 035 4282400

E-m

ation in the menu ..............................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................................

of the motor ..........................................................................................................................................................................................................................................................................

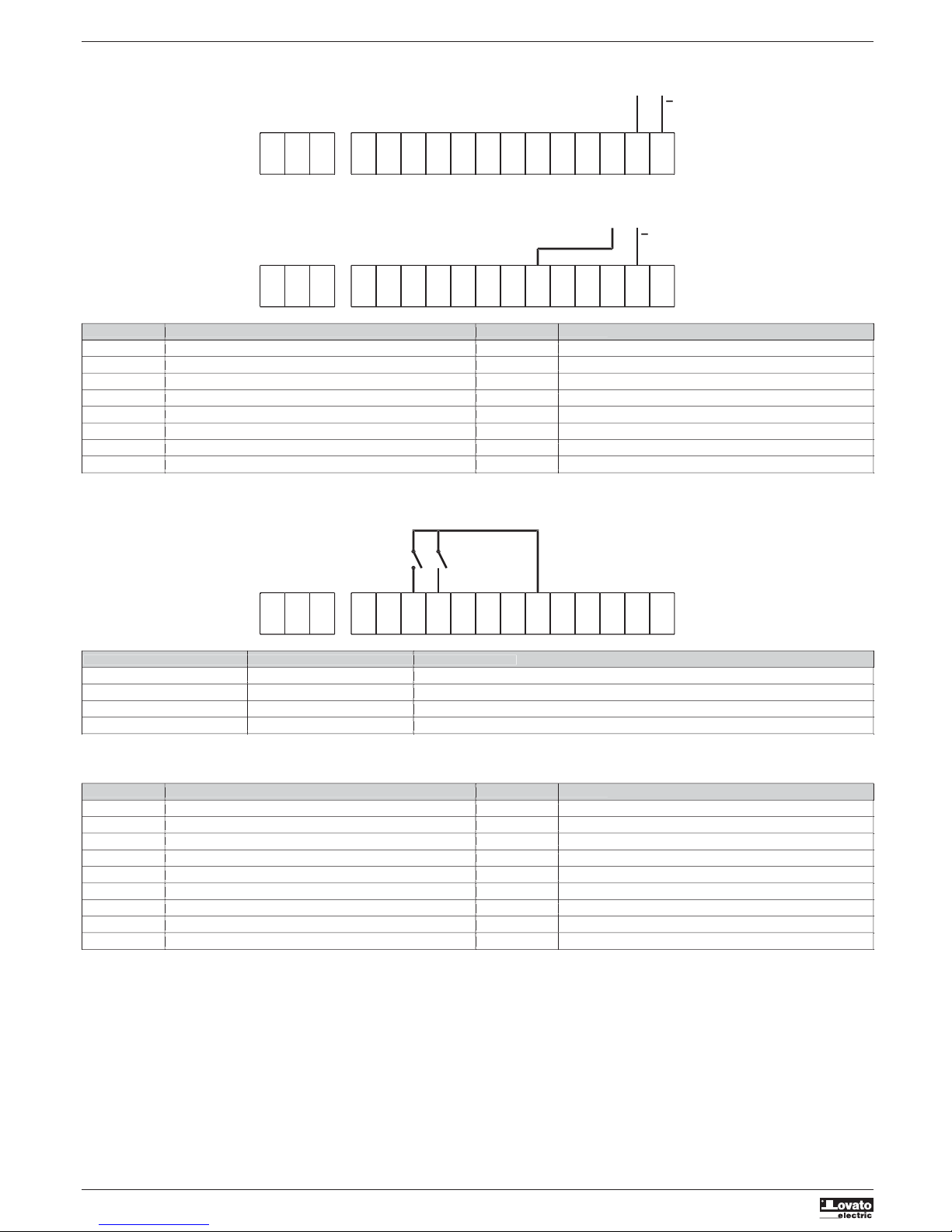

3.1 2-wires control from the flexible I/O terminal block ...........................................................................................................................................................................................................................................

3.2 From keypad .......................................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................

4.1 From keypad .......................................................................................................................................................................................................................................................................................................

4.2 From external potentiometer .............................................................................................................................................................................................................................................................................. 5

4.3 From analog input signal type 0-10V ................................................................................................................................................................................................................................................................. 5

4.4 From analog input signal t

pe 4-20mA ..............................................................................................................................................................................................................................................................

4.5 With preset frequency setpoints .........................................................................................................................................................................................................................................................................

4.6 From motor potentiometer

...................................................................................................................................................................................................................................................................... 7

4.7 PID

etpoint adjusted with keypad and feedback signal type 0-10V ...................................................................................................................................................................................................7

4.8 PID Control - Setpoint adjusted with keypad and feedback signal type 4-20mA ...............................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................

...................................................................................................................................................................................................................................................................................................

6.1 Configuration of the rela

output function .......................................................................................................................................................................................................................................................... 9

6.2 Configuration of the DO1 digital output function ................................................................................................................................................................................................................................................ 9

6.3 Configuration of the AO1 analog output function ............................................................................................................................................................................................................................................... 10

6.4 Enable of the start at power-up function (auto-restart) ...................................................................................................................................................................................................................................... 10

6.5 Command of digital inputs from PLC ................................................................................................................................................................................................................................................................. 1

onfiguration of the automatic (PID) / manual (frequency regulation) mode .................................................................................................................................................................................................... 1

ommon error codes ......................................................................................................................................................................................................................................................................................... 1

HE RUN AND STOP OF THE MOTOR?

ter 5

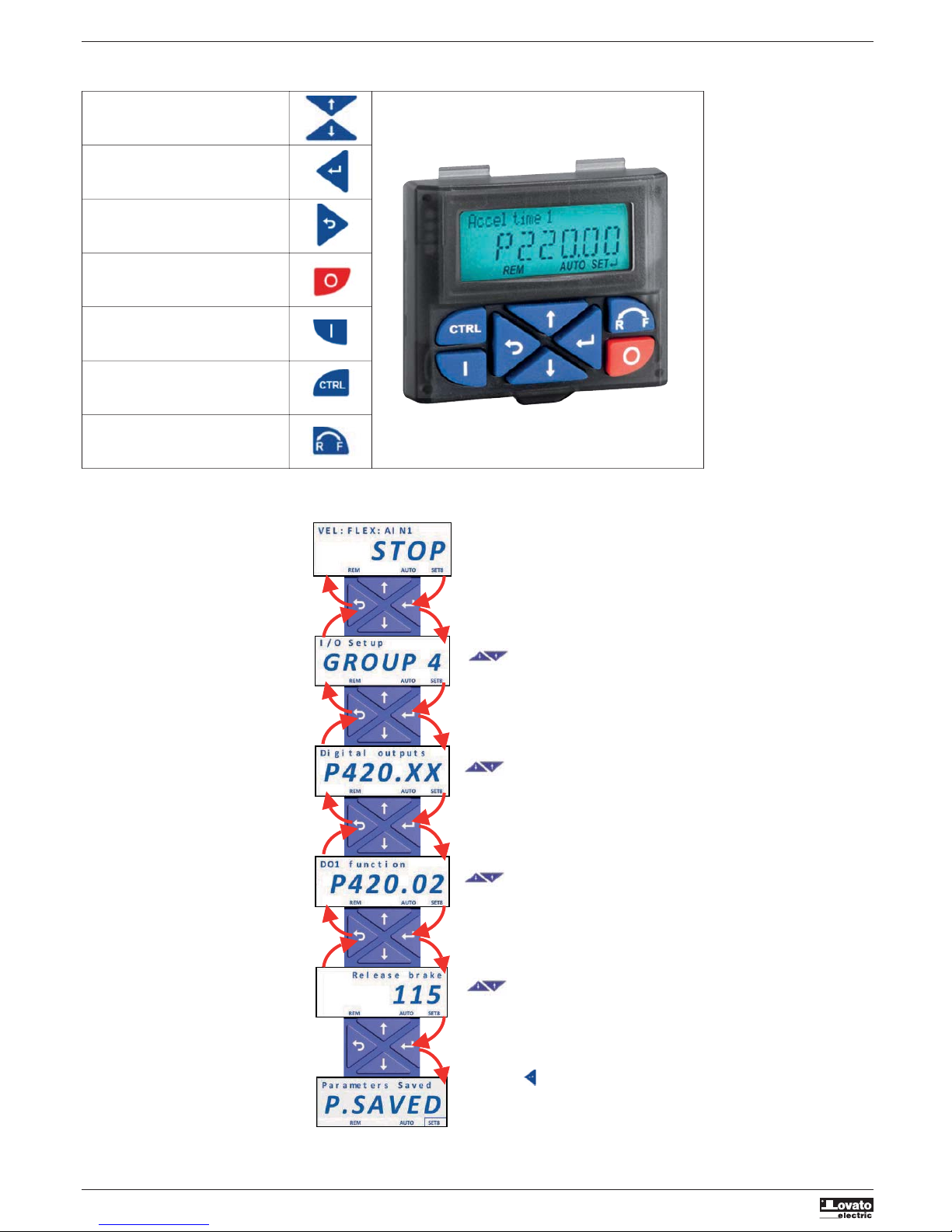

LEARN HOW TO NAVIGATE THE MEN

ee chapter 1

RESET PARAMETERS TO

ter 6

Steps to follow for the confi

uration of the variable speed drive: