SHS HT3 Series User manual

2

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

SHS automation products must be handled, installed and maintained by competent personnel only and

Instructed on the installation of automation components, and only for the purposes described in the user

manual. Installers must pay particular attention to the potential risks caused by mechanical and electrical hazards.

It is very important that applications and installations meet all applicable safety requirements.

Each installer is obliged to take responsibility for verifying their knowledge and understanding of everyone the applicable

safety standards.

Any use that does not meet the safety requirements can damage the equipment and injure the user.

SHS s.r.l. will not be held responsible, and will not take any responsibility for damage caused by products

handled and / or improperly installed, or in cases where the customer has permitted, or performed, modifications

and / or repairs not authorized by SHS s.r.l.

SHS drives are high-performance automation devices capable of generating rapid movements high forces.

Pay close attention, especially in the installation and application development phases.

Use only properly sized equipment for the application.

SHS devices are considered automation components and are sold as finished products to be installed only by qualified

personnel and in accordance with all local safety regulations.

Specialists must be able to recognize the possible dangers that may arise from programming, from the modification of the

parameter values and, in general, from mechanical, electrical and electronic equipment.

SHS s.r.l recommends always following the safety regulations. Failure to comply with these rules could cause damage to

people and / or things.

General precautions:

•This manual is subject to change due to product improvements, changes in specifications or improvements of the

manual itself.

•SHS s.r.l. is not responsible for damages to things and / or persons caused by incorrect installations and / or

modifications not authorized by the product.

Damaged control systems must not be mounted or put into operation to avoid injury people and damage to things.

Any modification or variation made to the drive systems is forbidden e involves the termination of any right to

warranty interventions or any liability obligation.

Security notes

3

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

Index

1 TECNICAL CHARACTERISTICS 4

1.1

Installation notes

4

1.2

DC power supply

4

1.3

Inputs & uputs

5

2 C NNECTI NS 6

2.1

Input/ utput connector

6

2.2

Power supply / motor connector

6

2.3

Enable Input

7

2.4

Encoder

7

3 SETTINGS 8

3.1

Parameters setting

8

3.2

Display messages

8

4 FUNCTI N M DES 9

4.1

Step/Dir mode

10

4.2

Modbus mode

11

4.3

Modbus registers

12

4.4

Winstar mode

14

4.5

Winstar commands

15

5 HT3 M DELS 18

4

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

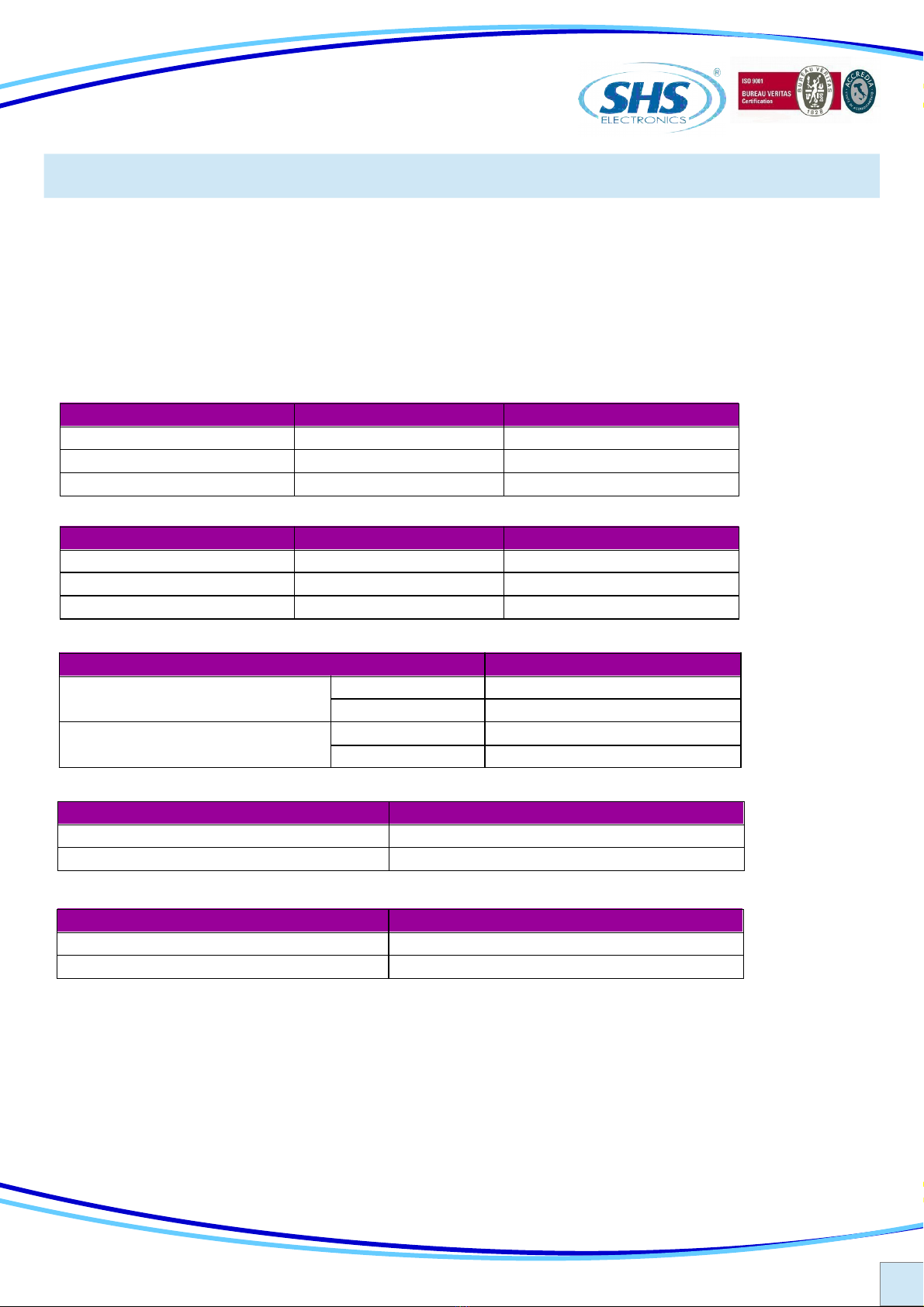

1. TECNICAL CHARACTERISTICS

1.1 Installation notes

ATTENTION

Danger o electric shock.

Only quali ied persons can handle the device.

Check the drive power terminals whenever voltage is removed be ore working on the device.

1.2 DC power supply

●Vdc nom : Nominal voltage value to which the driver may be powered.

●Vdc max: Maximum voltage value to which the driver can operate.

●Vdc min: Minimal voltage value to which the driver can operate.

●I max: Maximum phase current value.

●I min: Minimal phase current value.

●Operating temperature: For continuous working with phase current > 6A a orced cooling is necessary.

●Vcc: Logic power supply output.

●Icc max: Logic power supply current maximum

Unit HT320 HT350

Vdc nom

[V] 24 48

Vdc max

[V] 30 70

Vdc min

[V] 18 18

I max

[A] 4 8

I min

[A] 0.1 1.0

Operating temperature

[°C] 0 - 45 0 - 45

Vcc

[V] 15 15

Icc max

[A] 0.1 0.1

5

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

1.3 Inputs & Outputs

Digital inputs and outputs pins are isolated rom power

●Single Ended inputs IN1, IN2, IN3 compatible PNP input the common is COMIN_A pin.

●Single Ended inputs IN4, IN5, IN6 are NPN/PNP type selectable through COMIN_B pin.

●Outputs OUT1, OUT2, OUT3 are NPN/PNP type selectable through COMOUT.

Analog inputs ANIN1, ANIN2 pins and outputs ANOUT, VREF pins are not isolated rom power.

OUTPUTS VO TAGE EVE

PNP OUTPUT ON COM_OUT VOLTAGE - 2V

OFF 0V

NPN OUTPUT ON 2V

OFF COM_OUT VOLTAGE

ANA OG INPUTS VA UE

RANGE 0 to 10V

IMPEDANCE 150 KΩ

IN4, IN5, IN6 STANDARD TT (*)

LOW LEVEL 0V to 7V 0V to 2.5V

HIGH LEVEL 9V to 24V 3.5V to 5V

MAX CURRENT 10mA 4mA

IN1, IN2, IN3 STANDARD TT (*)

LOW LEVEL 0V to 7V 0V to 2.5V

HIGH LEVEL 9V to 24V 3.5V to 5V

MAX CURRENT 6mA 5mA

ANA OG OUTPUTS VA UE

RANGE 0 to 10V

MAX CURRENT 10 mA

(*) Special Release

6

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

2. CONNECTIONS

2.2 Power supply / Motor

connector

2.1 Input/Output connector

J1

SIGNAL FUNCTION

B2 B2 motor phase

B1 B1 motor phase

A2 A2 motor phase

A1 B1 motor phase

0V 0V power supply

+HV DC power supply input

J2 SIGNAL FUNCTION

21 FB- Fieldbus +

20 FB+ Fieldbus -

19 GND_FB 0V Fieldbus

18 GND 0V (+VCC, VREF, ANIN1,2, AN UT)

17 ANIN2 Analog input 2

16 ANIN1 Analog input 1

15 VREF Reference voltage output 10V

14 AN UT Analog output

13 +VCC Auxiliary voltage output 15V

12 IN6_EN Input 6 / ENABLE

11 IN5_DIR Input 5 / DIRECTI N

10 IN4_CLK Input 4 / CL CK

9 C MIN_B IN4,5,6 Common Reference

8 IN3_CHZ Input 3 / Encoder Z

7 IN2_CHB Input 2 / Encoder B

6 IN1_CHA Input 1 / Encoder A

5 C MIN_A IN1,2,3 Common Reference

4 UT3 utput 3

3 UT2 utput 2

2 UT1 utput 1

1 C M UT UT1,2,3 Common reference

7

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

2.4 Encoder

Encoder connection to check the motor position.

CH A

TYPICAL APPLICATION

SIGNAL FUNCTION

IN1 CH A

IN2 CH B

CH B

ENC DER

-V

2.3 Enable Input

To switch on the power o the motor must be connect a signal to Enable Input (IN6).

Without this signal the drive stop the motor, there is not a deceleration ramp, and the motor phases current goes to

zero.

It’s possible have a drive where the IN6 is a Disable Input, see drive models table option.

It’s possible to remove enable/disable unction and have an other spare input, see drive models table option.

SIGNAL FUNCTION

IN6 Enable

+V

7

6

5

4

3

2

1

14

13

12

11

10

9

8

21

20

19

18

17

16

15

FB-

FB+

GND-FB

GND

AIN2

AIN1

VREF

AN UT

+VCC

IN6-EN

IN5-DIR

IN4-CLK

C MIN-B

IN3-CHZ

IN2-CHB

IN1-CHA

C MIN-A

UT3

UT2

UT1

C M UT

8

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

3.1 Parameters setting

By using the buttons below the display (hereina ter re erred to as [] , [▼], [▲] ,[ѵ]) you can parameterize the

drive:

●To access to main menu, press [ѵ] per two seconds, it will visualize the irst available parameter.

●From main manu to select the desired parameter press the button [▼] or [▲].

●To visualize the actual value o parameter press [ѵ].

●From the parameter to change the value press [▼] or [▲].

●From the parameter to store the value press the button [ѵ] or two seconds and it will appear “memo” on the

display.

Some change require an automatic reset o the drive, or to a wait time to be e ective.

●From the parameter to come back at main menù without modi y any conditions, press [].

●From the main menu to go out press [].

●The password parameter use keyb [] to move the pointer beetwen the characters.

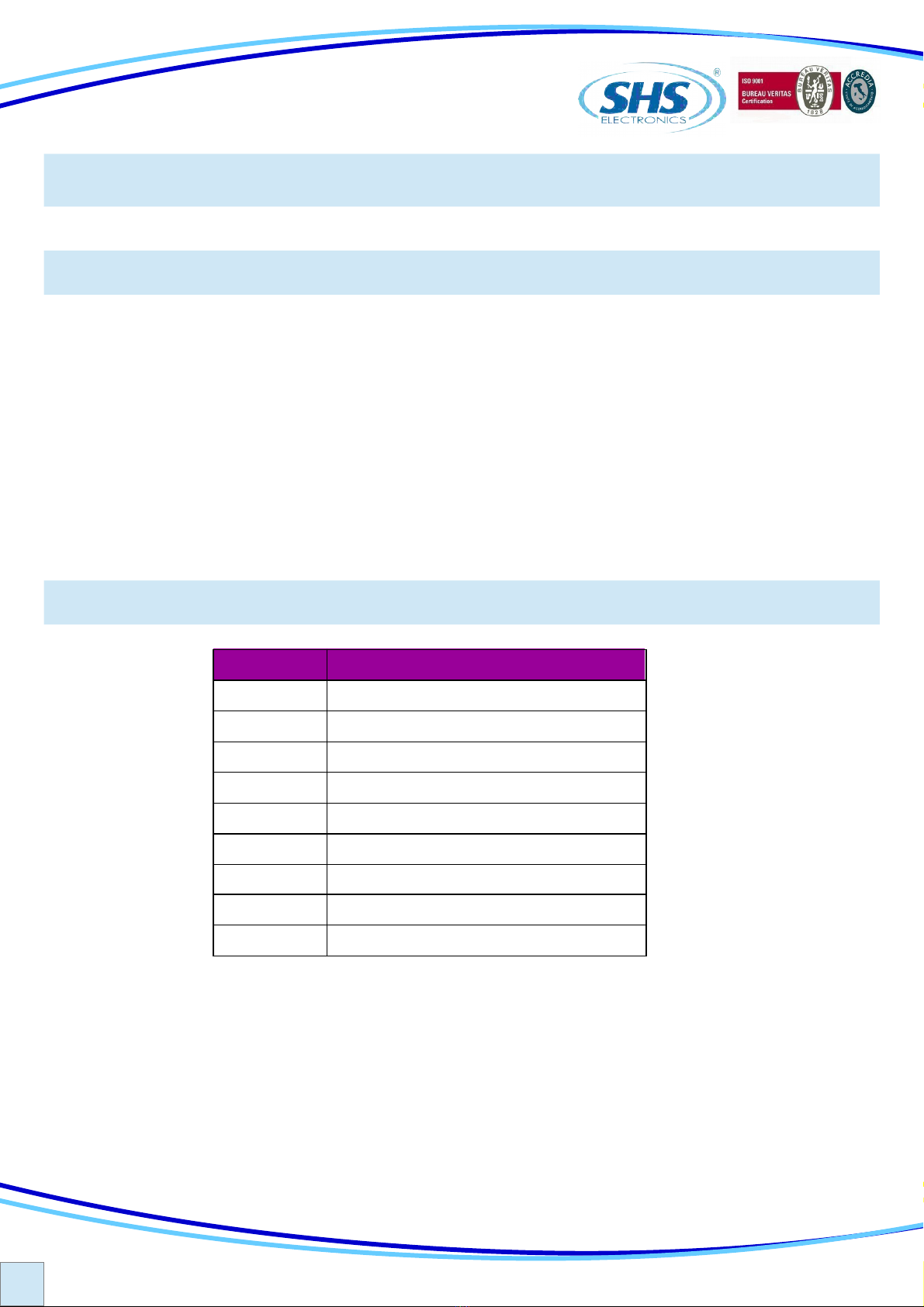

3.2 Display messages

3. SETTINGS

DISPLAY Description

rdy Drive K, motor stop

run Motor running

dis Drive disabled

temp ver temperature Error

uvoL Under Voltage Error

ovoL ver Voltage Error

oc ur ver Current Error

perr Generic Error

rSt Reset phase

In case o error, the drive will remove power to the motor.

To reset the over current and generic errors it’s necessary or switch o and on the drive.

To reset over temperature, under voltage or over voltage errors it’s necessary have the correct value.

9

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

4. FUNCTION MODES

It is possible to set di erent unction modes by the “Mode” parameter.

Mode DESCRIPTION

“ PD” Step/direction command

“Modb” Modbus Fieldbus protocol

“ Win” Winstar Fieldbus protocol

“Can ” Can pen Fieldbus protocol

Basic Drive in Step Direction can’t have Mode option.

Winstar and Modbus drive can have Step/direction mode.

10

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

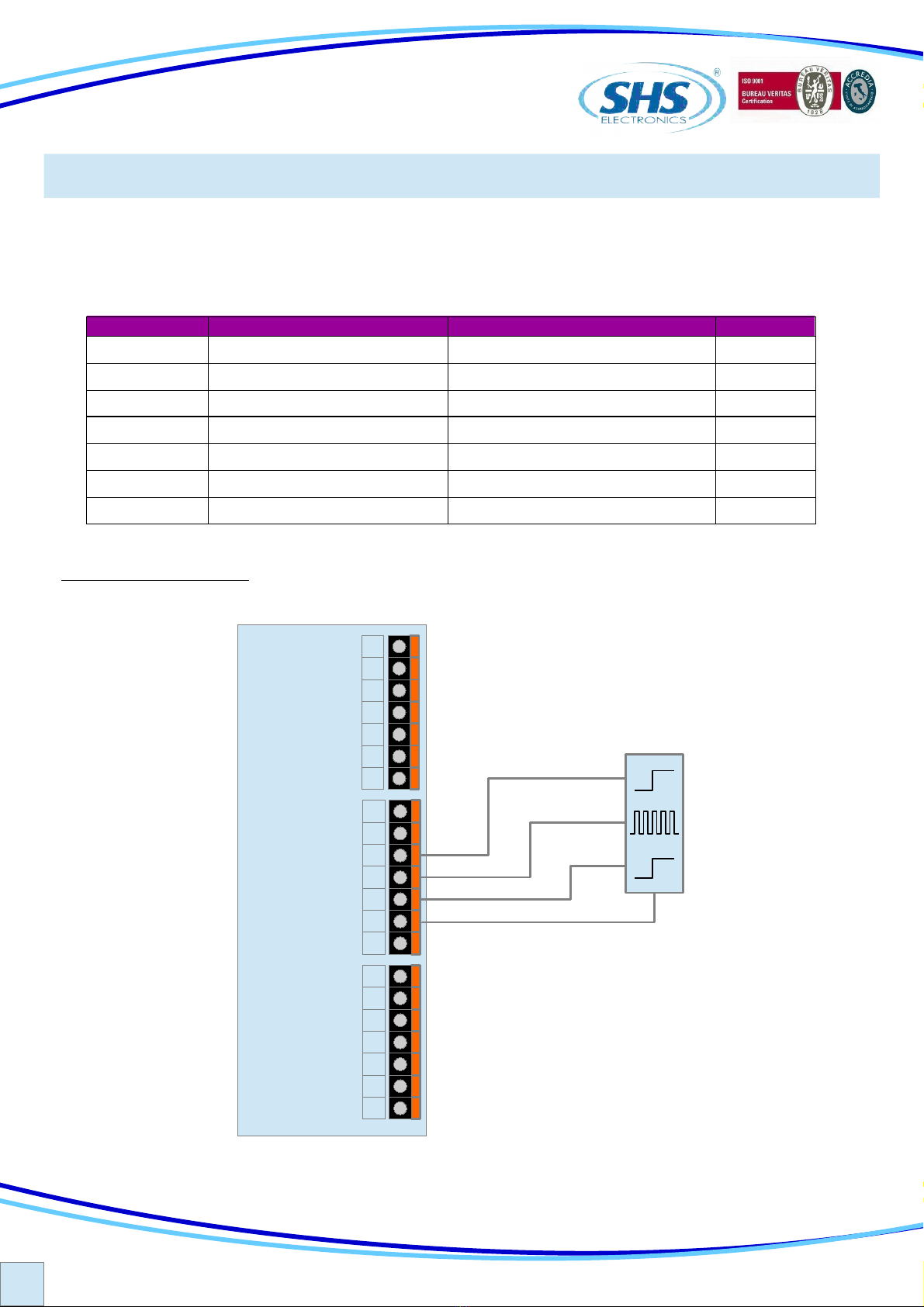

4.1 Step Direction Mode “ PD”

In Step/direction mode the drive execute a single step or each rising edge o the step-in signal

IN4 step in clock (Maximum requency 60KHz)

IN5 de ines the direction rotation.

IN6 enable the drive.

TYPICAL APPLICATION

PARAMETERS Function alues Reset

0par

Reset Eeprom values n Unaffected

c urr

Set the phase current [mA] See drive models table option 1000

res

Set the resolution [1/n steps] 1/1, 1/2, 1/4, 1/8, 1/16 1/2

redi

Set the reduction current value Zero Current, Imax/4, Imax/2, Imax Imax/4

redt

Set the reduction current time 10ms to 300ms 10

Firm

Firmware Release Variable Unaffected

pass

Password Alphanumeric value “----”

STEP

DIR

7

6

5

4

3

2

1

FB-

FB+

GND-FB

GND

AIN2

AIN1

VREF

AN UT

+VCC

IN6-EN

IN5-DIR

IN4-CLK

C MIN-B

IN3-CHZ

IN2-CHB

IN1-CHA

C MIN-A

UT3

UT2

UT1

C M UT

ENABLE

PLC

14

13

12

11

10

9

8

21

20

19

18

17

16

15

11

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

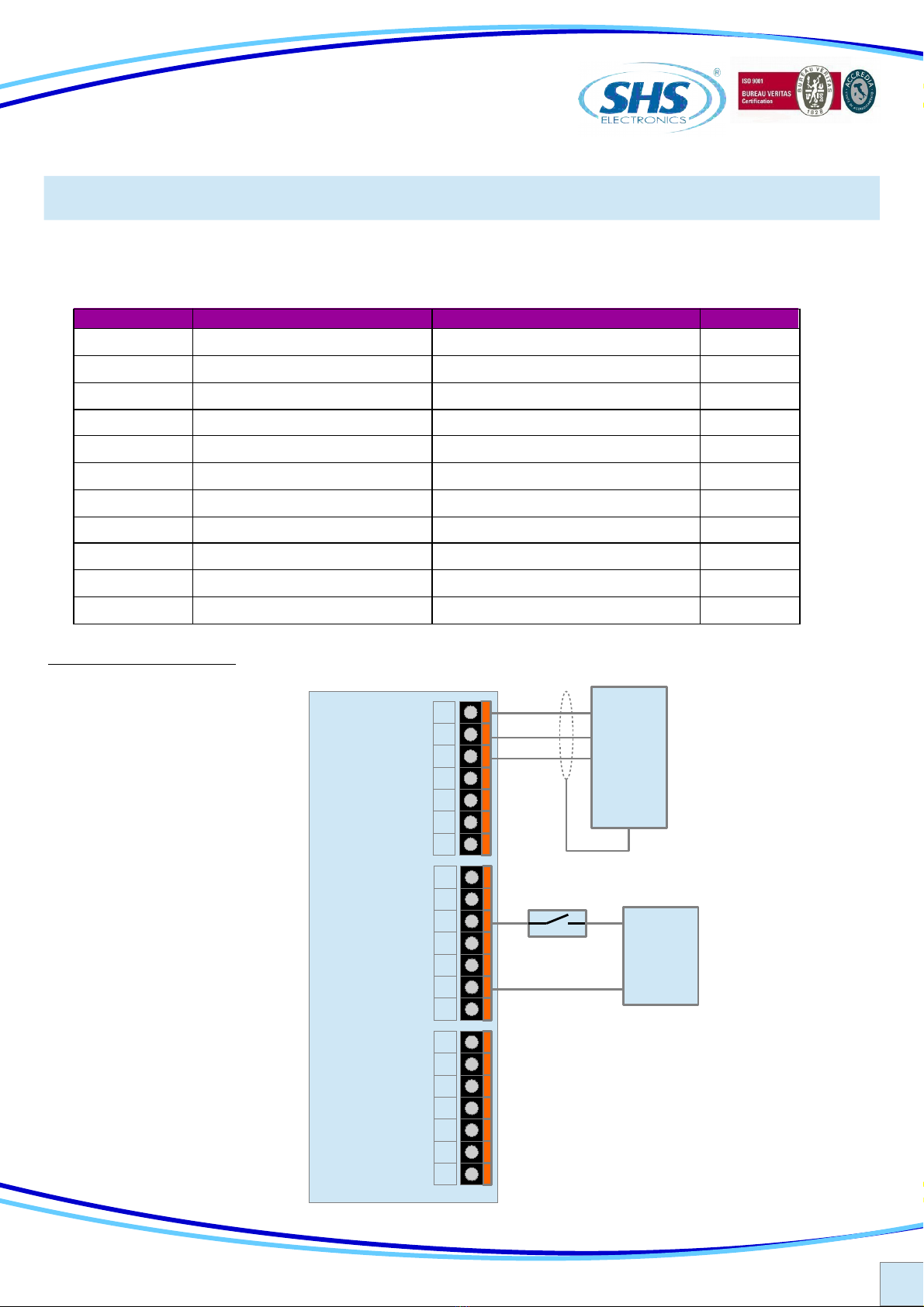

The drive can support MODBUS-RTU protocol.

It is possible to set Address, Baud-rate and Parity.

Data ormat is N,8,1.

4.2 Modbus Mode “MODB”

TYPICAL APPLICATION

PLC

RS485

shield

7

6

5

4

3

2

1

14

13

12

11

10

9

8

21

20

19

18

17

16

15

FB-

FB+

GND-FB

GND

AIN2

AIN1

VREF

AN UT

+VCC

IN6-EN

IN5-DIR

IN4-CLK

C MIN-B

IN3-CHZ

IN2-CHB

IN1-CHA

C MIN-A

UT3

UT2

UT1

C M UT

0V

D+

D-

PARAMETERS Function alues Reset

0par

Reset Eeprom values n Unaffected

c urr

Set the phase current [mA] See drive models table option 1000

aud

BaudRate RS485[Kbps] 9.6, 19.2, 38.4, 57.6, 115.2 19.2

par

Parity RS485 “ no”, “even”, “ odd” “ no”

Addr

Node Modbus Address 0 to 31 1

Mode

Mode Function “ PD”, “Modb” “Modb”

res

Set the resolution [1/n steps] 1/1, 1/2, 1/4, 1/8, 1/16 1/2

redi

Set the reduction current value Zero Current, Imax/4, Imax/2, Imax Imax/4

redt

Set the reduction current time 10ms to 300ms 10

Firm

Firmware Release Variable Unaffected

pass

Password Alphanumeric value “----”

24 DC

12

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

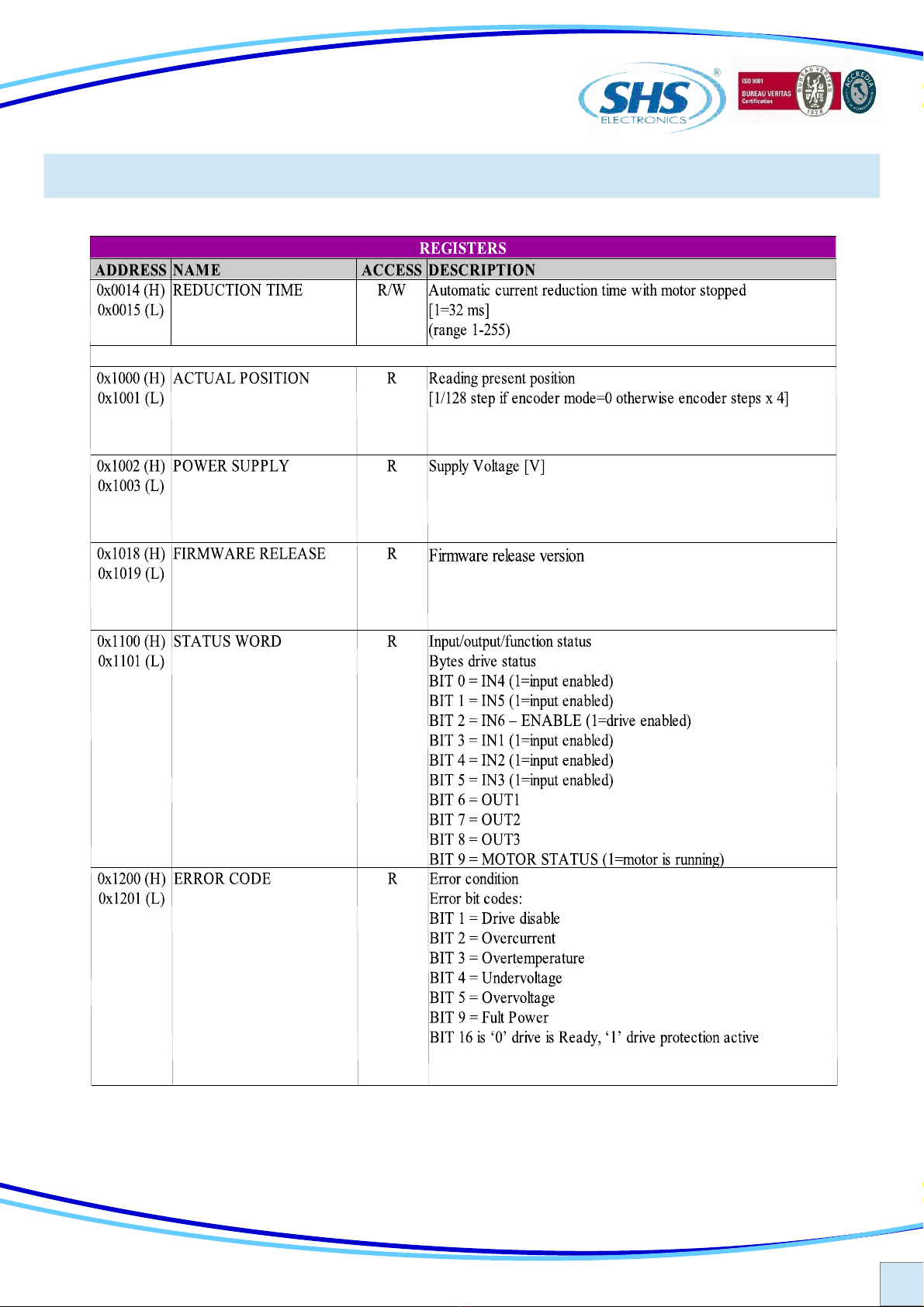

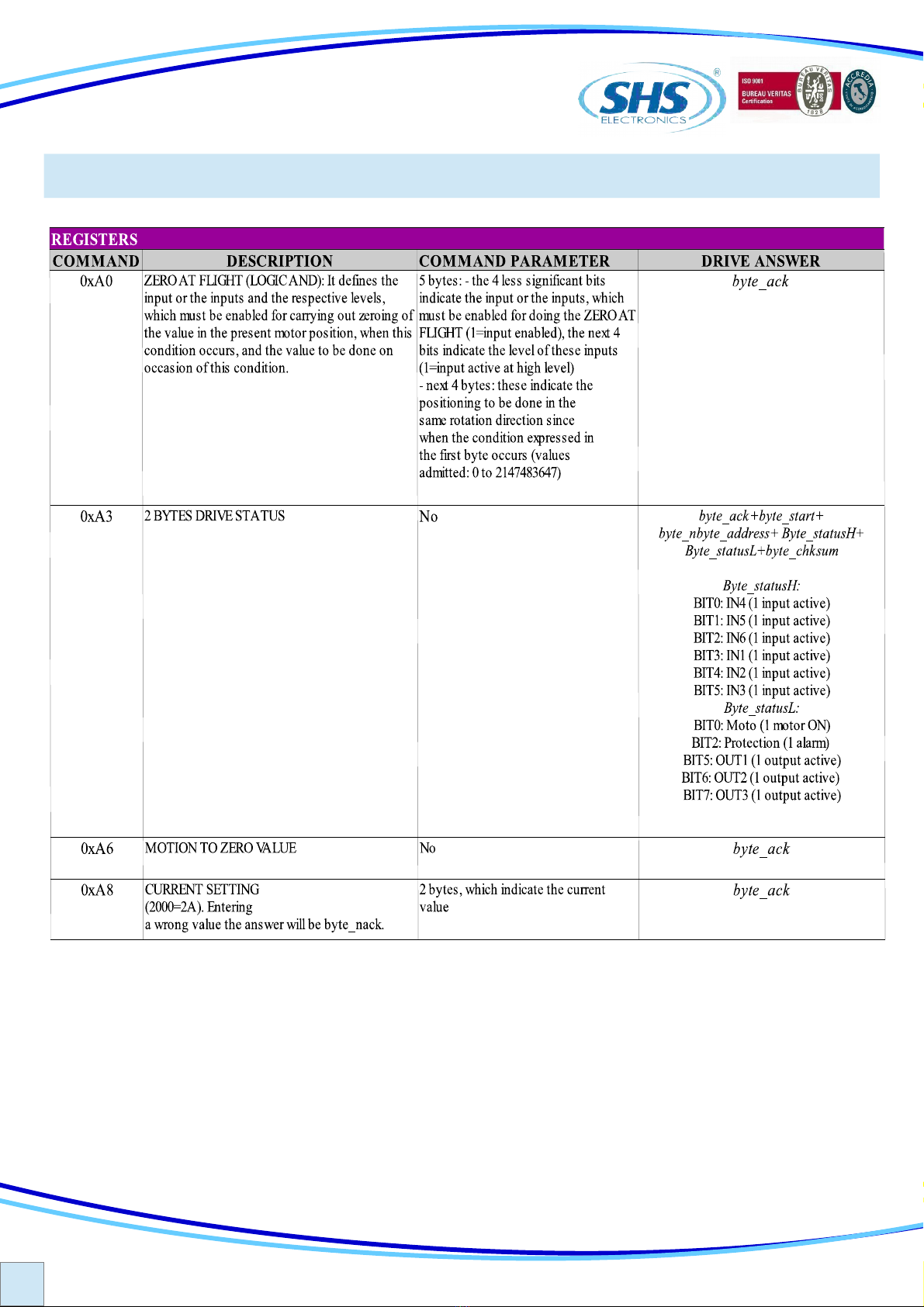

4.3 Register table

13

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

Register table (cnt)

14

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

The drive can support WINSTAR proprietary protocol.

It is possible to set Address, Baud-rate and Parity.

Data ormat is N,8,1.

4.4 Winstar Mode “ Uin”

TYPICAL APPLICATION

PLC

RS485

shield

7

6

5

4

3

2

1

14

13

12

11

10

9

8

21

20

19

18

17

16

15

FB-

FB+

GND-FB

GND

AIN2

AIN1

VREF

AN UT

+VCC

IN6-EN

IN5-DIR

IN4-CLK

C MIN-B

IN3-CHZ

IN2-CHB

IN1-CHA

C MIN-A

UT3

UT2

UT1

C M UT

0V

D+

D-

PARAMETERS Function alues Reset

0par

Reset Eeprom values n Unaffected

c urr

Set the phase current [mA] See drive models table option 1000

aud

BaudRate RS485[Kbps] 9.6, 19.2, 38.4, 57.6, 115.2 19.2

par

Parity RS485 “ no”, “even”, “ odd” “ no”

Addr

Node Modbus Address 0 to 31 1

Mode

Mode Function “ PD”, “ Uin” “ Uin”

res

Set the resolution [1/n steps] 1/1, 1/2, 1/4, 1/8, 1/16 1/2

redi

Set the reduction current value Zero Current, Imax/4, Imax/2, Imax Imax/4

redt

Set the reduction current time 10ms to 300ms 10

Firm

Firmware Release Variable Unaffected

pass

Password Alphanumeric value “----”

24 DC

15

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

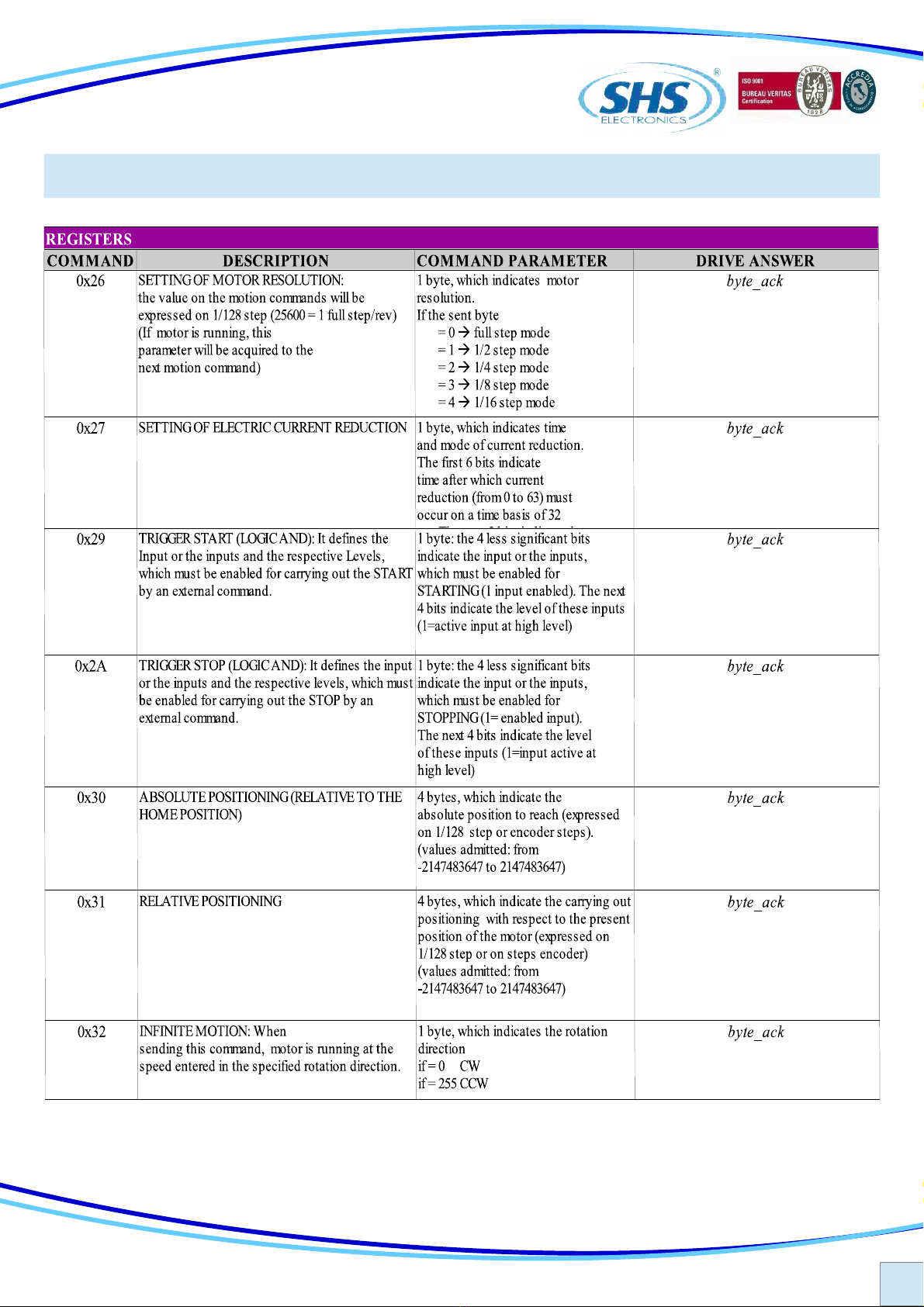

4.5 Command table

16

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

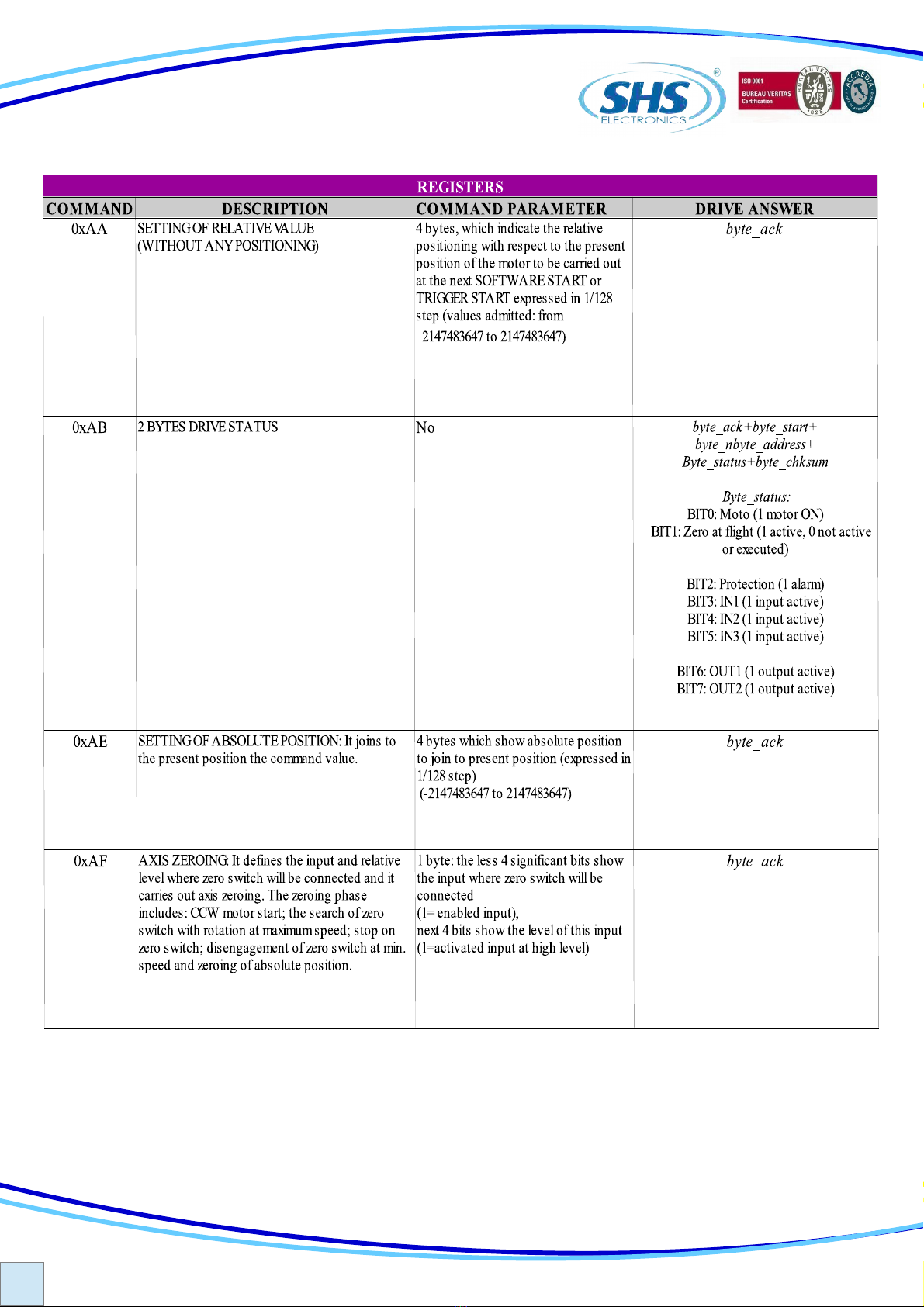

Command table (cnt)

17

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

Command table (cnt)

18

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

19

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

Command table (cnt)

20

ENG

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

CODE yyyyOPTION

1 Encoder TTL

2 Input TTL

4 Display Bootm

8 EEprom special Firmware

16 Signal crimp connector

32 Power Screw connector

64 IN6 Disable input

128 IN6 spare input

The de aul con iguration it:

●Step Direction Command

●Input rom 12 to 24V

●Power and Signal Pluggable Connector

(*) not available or this drive

EXAMPLE 1: the de ault con iguration will become option 0 ( 00000 )

EXAMPLE 2: TTL Input + EEprom Firmware, will become option 2+8 = 10 ( 00010 )

HT3x1KK - yyyyy / Zzz

FIE DBUS:

WS = RS485 SHS Protocol

MB = Modbus

CO = CanOpen

OPTION:

View the ollowing table

SIZE:

2 = 4A 20..28Vdc

3 = 4A 20..60Vdc

5 = 8A 20..60Vdc

SPECIA VERSION:

Dzz = Dedicate So tware

Szz = Modi y Hardware (*)

5. HT3 MODELS CODE

Other manuals for HT3 Series

1

This manual suits for next models

2

Table of contents

Other SHS DC Drive manuals