2

Operating Safety

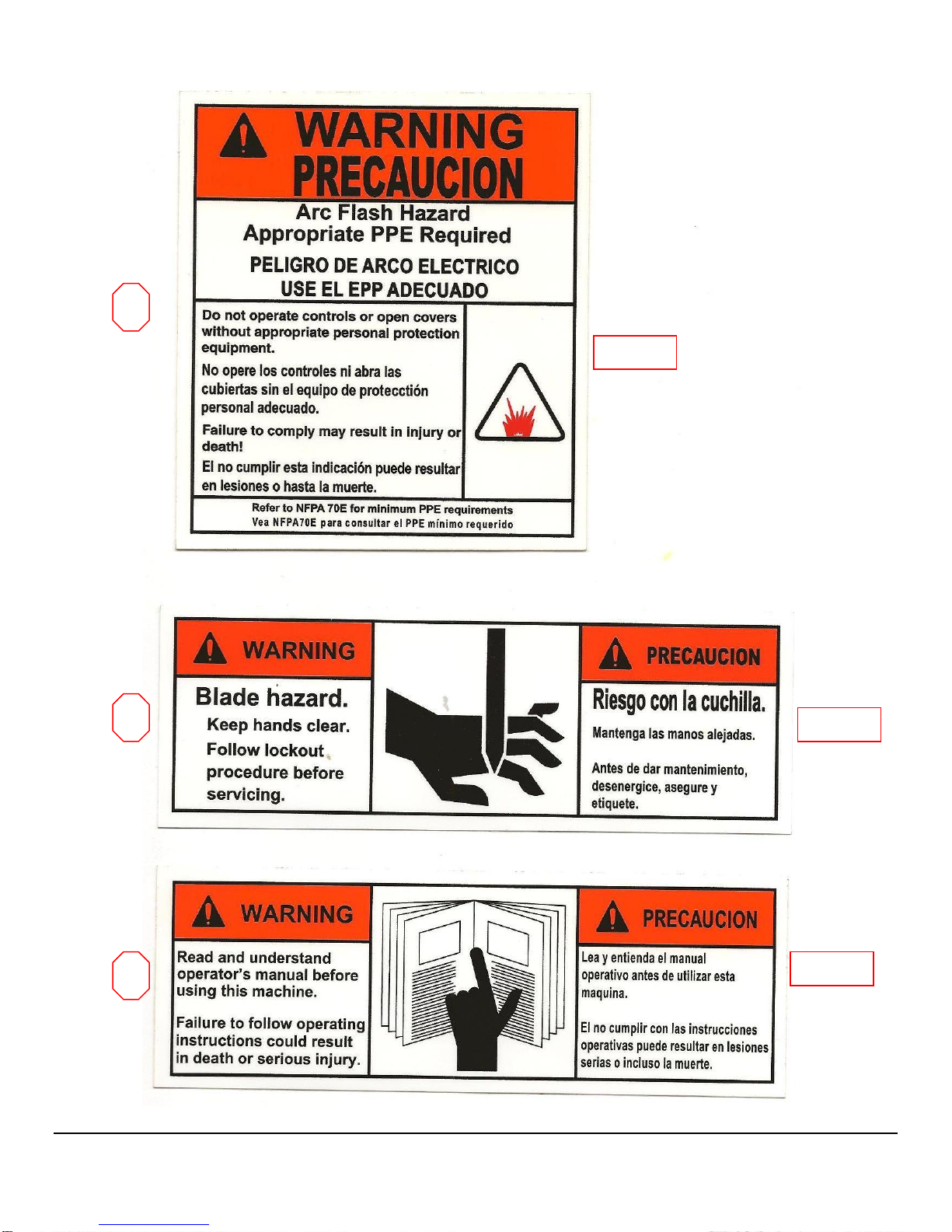

Observe the warnings and cautions below when using the Little David LD24 case sealer.

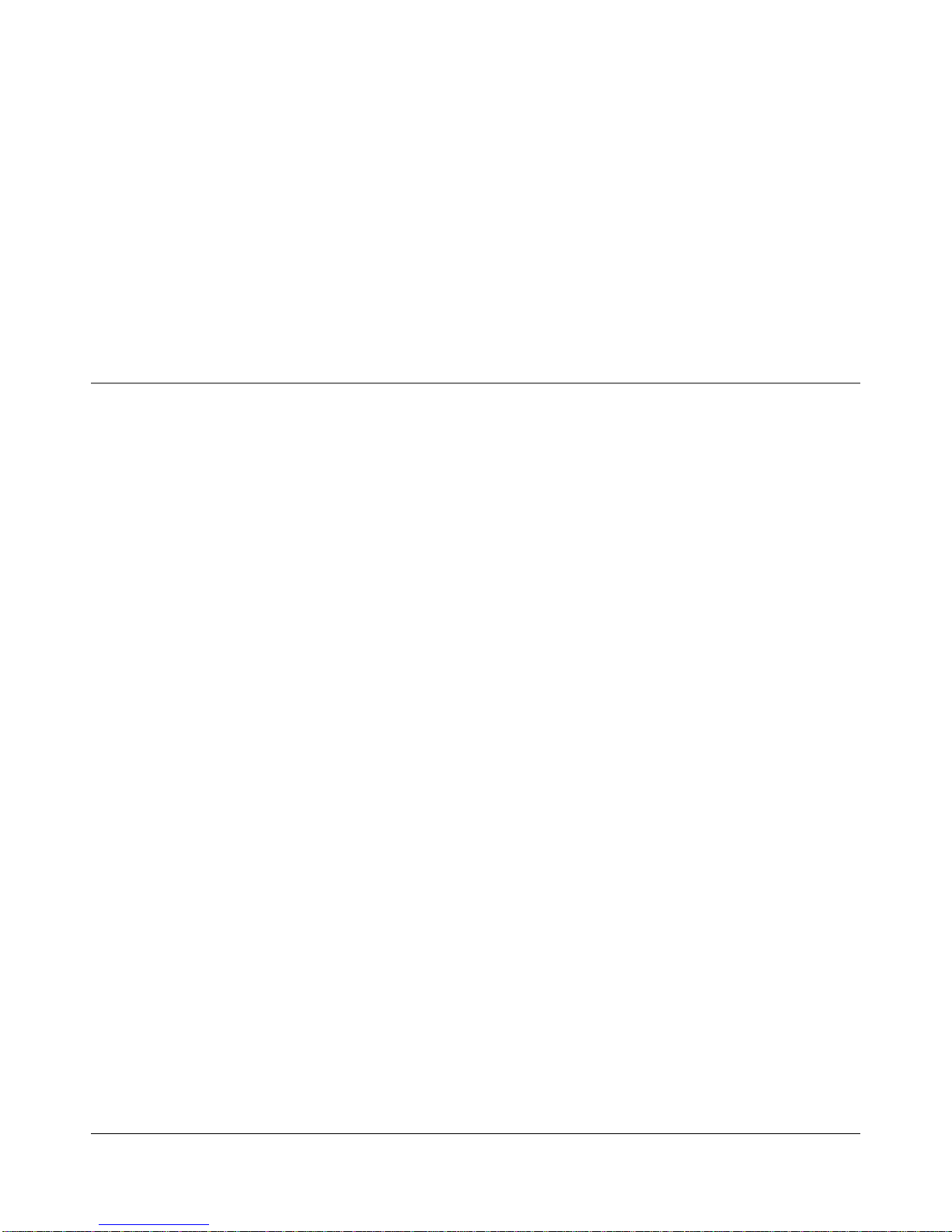

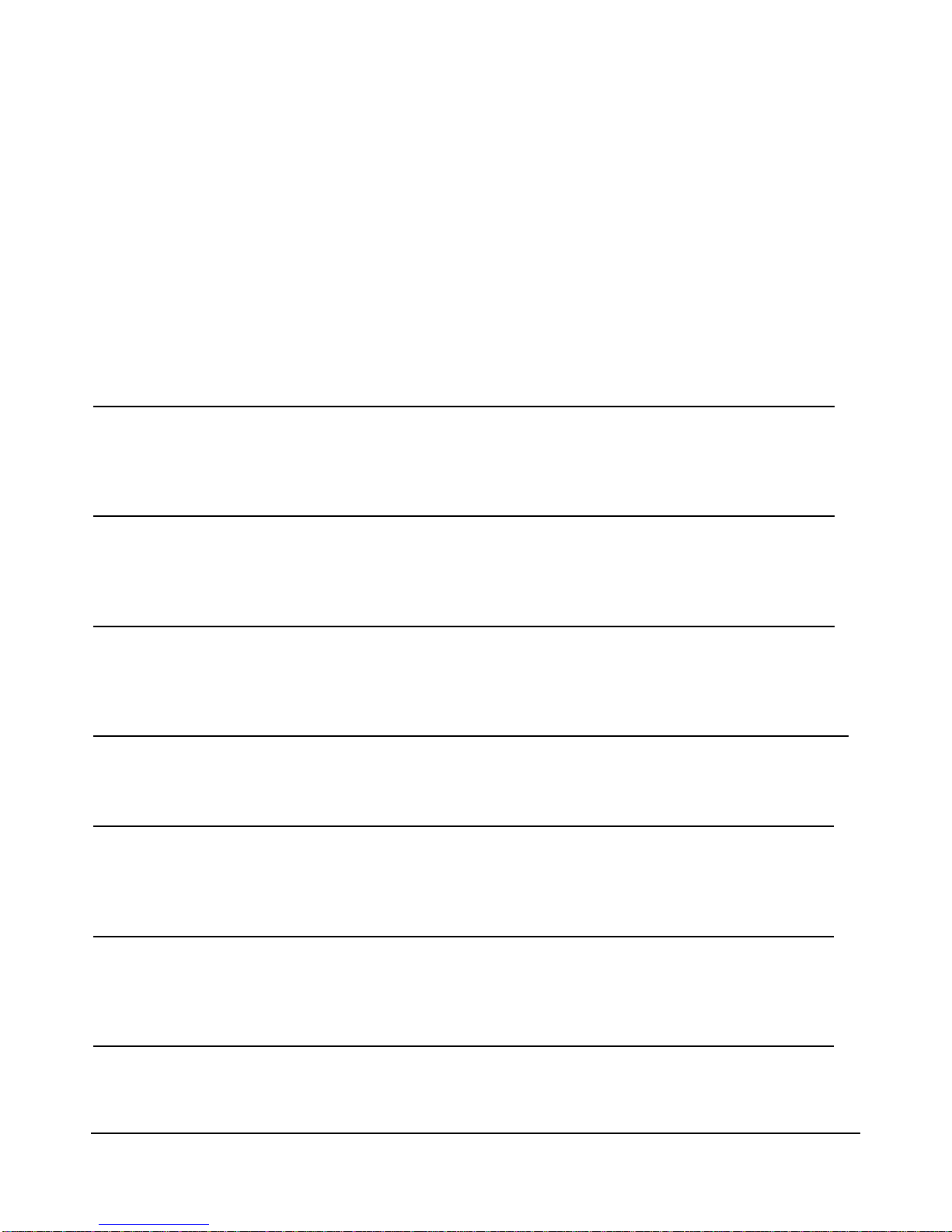

Within this manual on pages 4 -6, all safety labels are depicted with location and part

number. If a safety, label is missing or not legible it must be replaced immediately.

Failure to follow safety labels can lead to injury or damage to the machine.

Instruction: Requirement to System Operation

An electrical receptacle must be located near the machine. The line cord

connection to the receptacle is the disconnect means for the machine. The

receptacle must be located in an area that is easily accessible to all personnel.

Warning: Potential Bodily Injury

Always disconnect all sources of energy to the machine before performing maintenance.

Sources of energy include electrical and pneumatic. Refer to your company’s lock out

tag out procedures.

Never bypass or remove safety guards from the machine or tape cartridge.

Never override safety devices such as Emergency Stop switches.

Never adjust the machine or tape cartridges when the machine is operating.

Never place hands or body inside confines of the machine unless top head assembly is

locked in place and all power sources are locked out.

Never wear jewelry, loose clothing, such as ties, scarves etc and long hair must be pulled

back when operating this machine.

Never pull a jammed box out of the machine while it is in operation. Stop machine and

open the side drives and raise the head assembly.

When feeding a box into the machine manually avoid the rear flap folding mechanisms.

Chapter

2

Instruction:

arning:

Warning:

Warning:

Warning:

Warning:

Warning:

Warning:

Warning: