BOLT, 3/4-10 X 2.00

HEX

LOCKWASHER

BRACKET, COVER

RETAINER

COVER, POST

TOP HUB

LIFESTYLE

POST TOP

POLE

NOTE:

ATTENTION:

CAUTION:

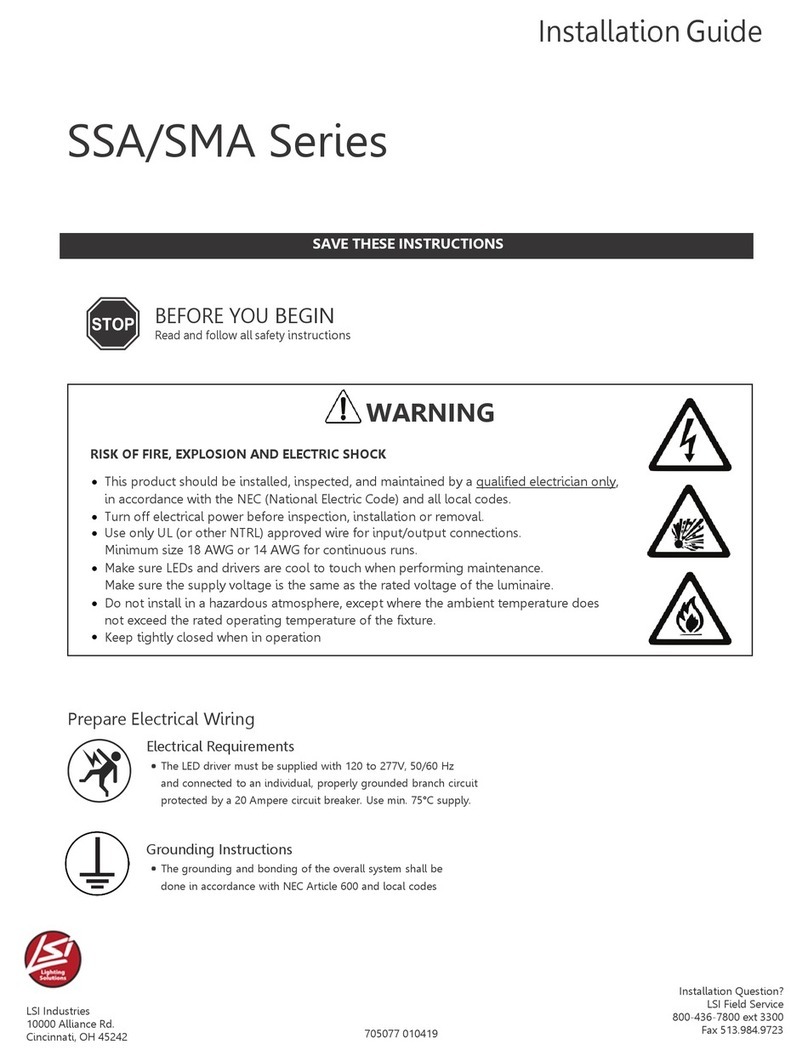

WARNING:

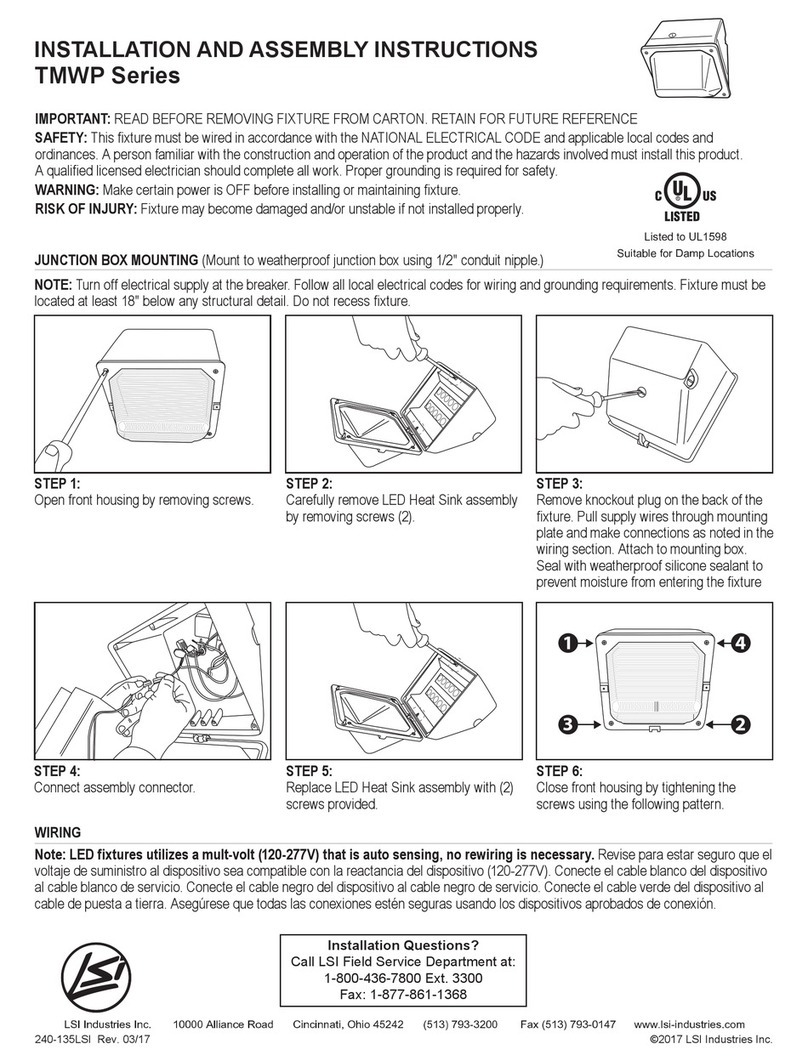

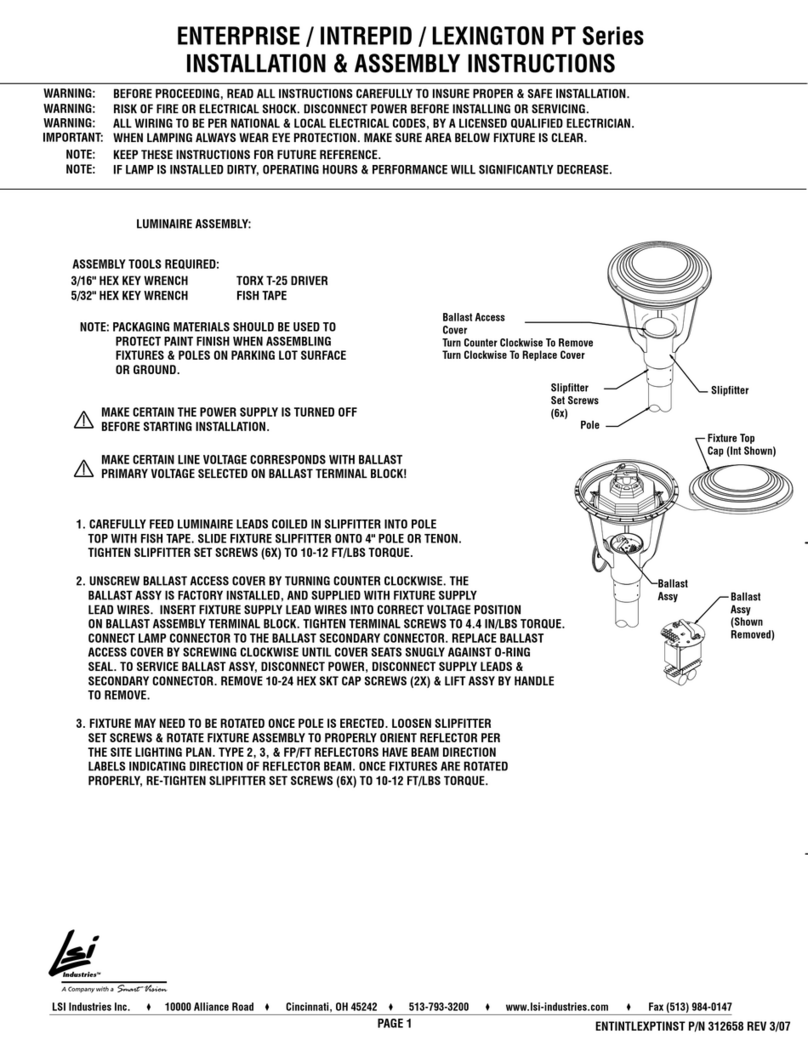

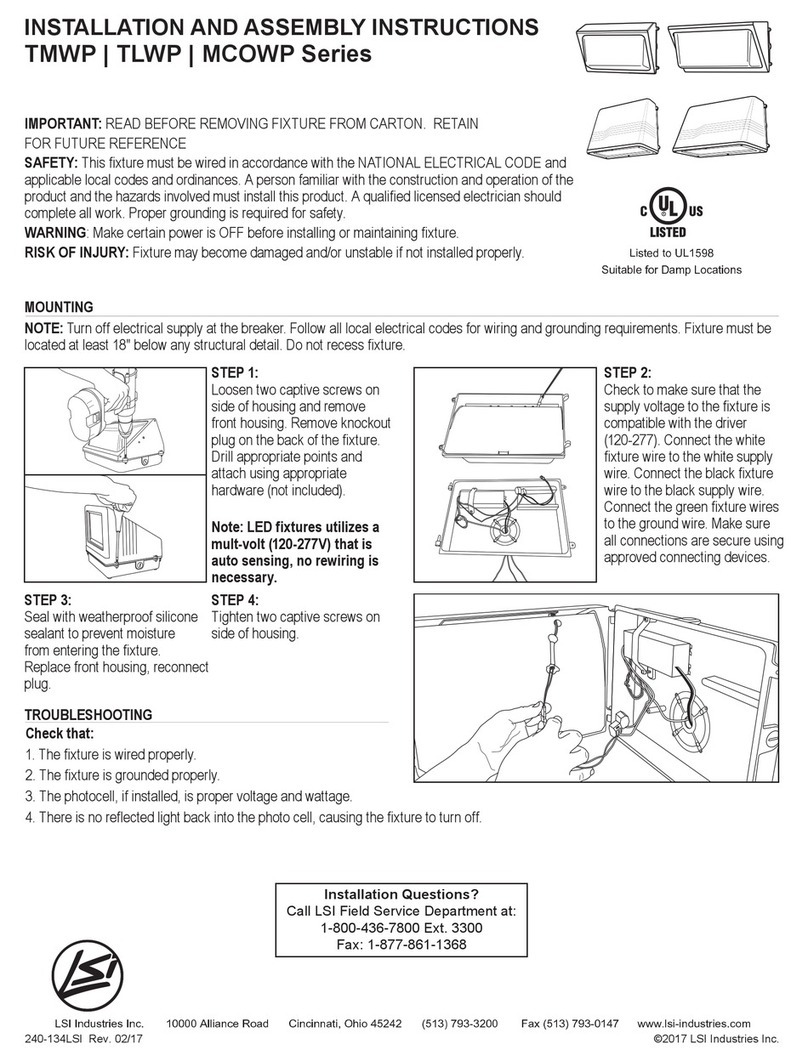

POST TOP LUMINAIRE ASSEMBLY:

THIS LUMINAIRE MUST BE INSTALLED BY A QUALIFIED LICENSED ELECTRICIAN.

THIS LUMINAIRE IS EQUIPPED WITH A MULTI-TAP BALLAST. CONNECT INCOMING VOLTAGE LEAD TO SELECTED

VOLTAGE ON BALLAST ( 120, 208, 240, & 277V). ALL UNUSED LEADS MUST BE INDIVIDUALLY INSULATED.

THIS LUMINAIRE MUST BE INSTALLED PER LOCAL AND NATIONAL ELECTRIC CODES. THIS LUMINAIRE MUST

BE GROUNDED! FAILURE TO DO SO MAY RESULT IN SERIOUS PERSONAL INJURY.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

INSTALL TRANSITION SUB-ASSEMBLY. ALIGN MOUNTING HOLES AS SHOWN &

INSTALL 1/4-20 X .75 LONG CAP SCREWS (3X). TIGHTEN TO 3-4 FT/LBS TORQUE.

(N) NON-

LUMINOUS ASSY

(V) VERTICAL

LOUVER ASSY

1/4 -20 x .75L

HEX SOCKET CAP

SCREW (3X)

HARNESS, LM/S

1/4 -20 x .75L

HEX SOCKET CAP

SCREW (3X)

1/4 -20 x .75L

HEX SOCKET CAP

SCREW (3X)

FIG. 4

(H) HORIZONTAL

LOUVER ASSY

GASKET,

O-RING

(N ONLY)

ROTATE BALLAST ASSY

& TIGHTEN (3X) 1/4-20 X 5/8 CAP

SCREWS TO 3-4 FT/LBS TORQUE

FIG. 3FIG. 2

LM/S BALLAST ASSY

CONNECT POWER

WITH HIGH TEMP

WIRE NUT (3X)

FIG.1

ASSY, LM/S POST TOP

SHADE A, B, OR F

1. REMOVE POST TOP SHADE ASSY FROM MASTER PACKING CARTON. BOLT POST

TOP SHADE ASSY TO POST TOP POLE WITH LOCKWASHER & 3/4-14 BOLT.

ROTATE LUMINAIRE TO ORIENT REFLECTOR PER SITE LIGHTING PLAN.

TIGHTEN 3/4-14 BOLT TO 12-14 FT/LBS TORQUE. PULL SUPPLY LEADS

THRU POLE & POST TOP MOUNTING HUB.

HUB, POST TOP

LUMINAIRE MTG

ASSEMBLY TOOLS REQUIRED: 3/16" HEX KEY WRENCH (BONDHUS) P/N 34296

5/32" HEX KEY WRENCH, 5/16" NUT DRIVER,

1-1/4" OPEN END WRENCH

2. CONNECT SUPPLY LEADS IN MOUNTING HUB TO LUMINAIRE LEADS. FOLD & CABLE TIE

LEADS TO STRAIN RELIEF. INSTALL HUB COVER RETAINER BRACKET & COVER

ON HUB.

NOTE: PACKAGING MATERIALS SHOULD BE USED TO PROTECT PAINT FINISH

WHEN ASSEMBLING LUMINAIRE & POLE ON PARKING LOT SURFACE

OR GROUND.

MAKE CERTAIN THE POWER SUPPLY IS TURNED OFF BEFORE STARTING

INSTALLATION.

3. (SEE FIG. 2) WIRE SUPPLY VOLTAGE TO CORRECT VOLTAGE TAP ON BALLAST SUB-ASSY.

ALL UNUSED BALLAST LEADS MUST BE INDIVIDUALLY INSULATED. USE HIGH TEMP. (150°C)

RATED CONNECTORS SUPPLIED WITH BALLAST.

4. (SEE FIG. 3) SLIDE BALLAST SUB-ASSY INTO CROWN. ROTATE ASSEMBLY TO END

OF KEYHOLE SLOTS & TIGHTEN 1/4-20 HEX SKT CAP SCREWS TO 3-4 FT/LBS TORQUE

WITH 3/16" HEX KEY. BE CAREFUL TO NOT PINCH WIRING BETWEEN BALLAST MTG. PLATE

& CROWN WHEN INSTALLING ASSEMBLY.

5. (SEE FIG. 4) INSTALL TRANSITION ASSEMBLY TO CROWN

ASSEMBLY. ALIGN BALLAST PLATE WIRING CONNECTORS

WITH WIREWAYS IN (V) & (H) TRANSITIONS. THIS IS NOT

NECESSARY ON (N) TRANSITION. ALIGN HOLES & INSERT

1/4-20 X .75 HEX SKT CAP SCREWS USING 3/16" BONDHUS

HEX KEY, & TIGHTEN EVENLY TO 3-4 FT/LBS TORQUE.

ON (N) TRANSITION ONLY MAKE CERTAIN O-RING SEAL

IS SEATED IN GROOVE. DO NOT PINCH O-RING WHEN

INSTALLING (N) STYLE TRANSITION INTO CROWN AS

SEAL DAMAGE MAY OCCUR.

Lifestyle

®

Series

Post Top Mount Installation Instructions