Extender

Table of contents

Print status 08/2023, English

TABLE OF CONTENTS

Table of contents ......................................................................................................... 3

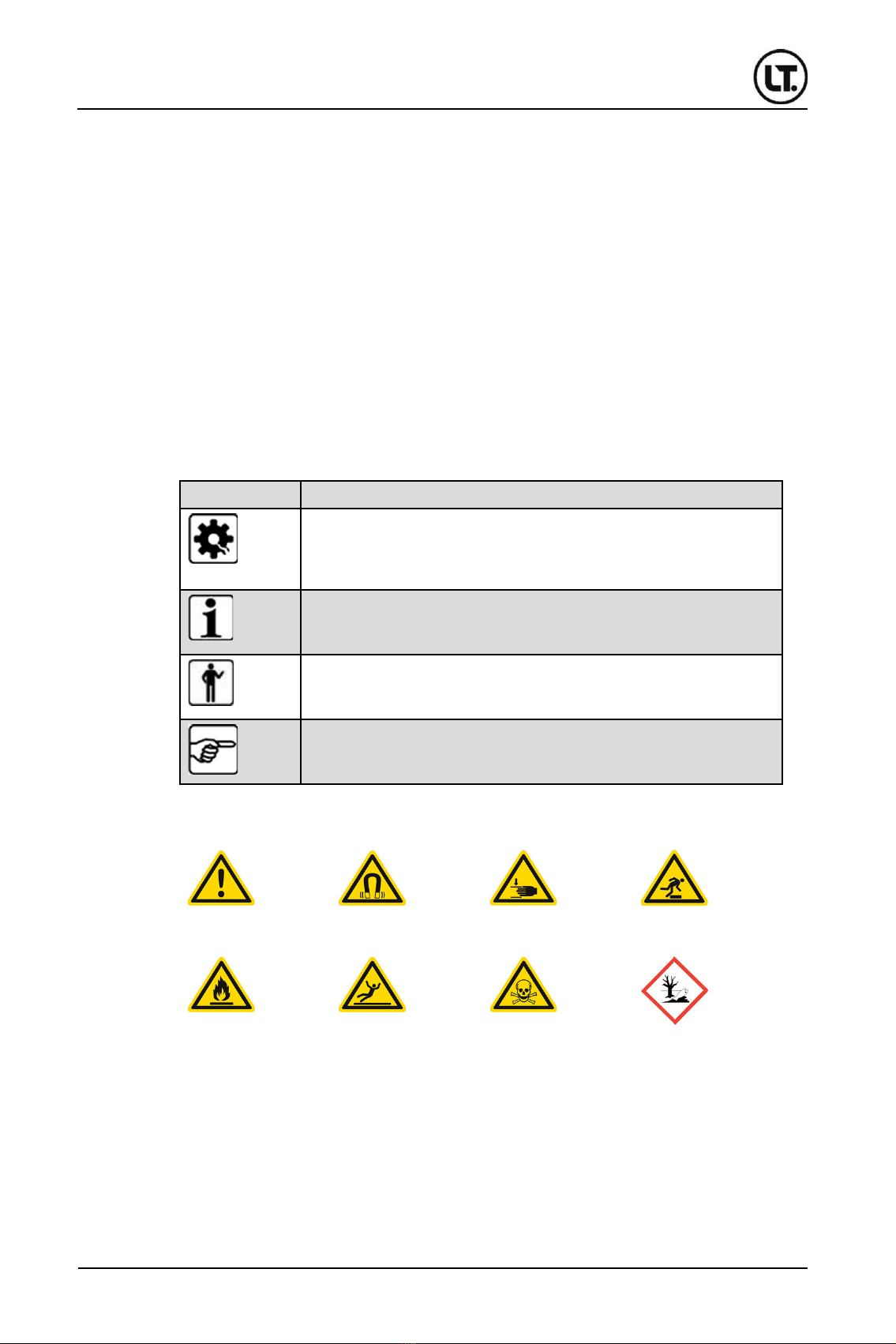

Purpose of the operating instructions....................................................................... 5

Orientation in the operating instructions .................................................................. 5

1Identification ................................................................................................. 7

1.1 Product labeling .................................................................................................... 7

1.2 Manufacturer's data............................................................................................... 7

1.3 Nameplate............................................................................................................. 8

1.4 Declaration of conformity....................................................................................... 9

2Basic safety instructions ........................................................................... 10

2.1 Operator's duty of care........................................................................................ 10

2.2 General occupational safety................................................................................ 10

2.2.1 Personnel qualification............................................................................. 10

2.2.2 Authorized personnel ............................................................................... 11

2.3 Residual hazards ................................................................................................ 11

2.3.1 Hazards due to electrical energy.............................................................. 11

2.3.2 Hazards due to magnetism ...................................................................... 11

2.3.3 Hazards due to leakage and hose lines ................................................... 12

2.3.4 Hazards due to cooling lubricant (KSS) ................................................... 13

2.4 Safety instructions of the extender ...................................................................... 14

2.5 Emergency information ....................................................................................... 14

3Description, structure and function.......................................................... 15

3.1 Intended use ....................................................................................................... 15

3.2 Reasonably foreseeable misapplication.............................................................. 15

3.3 Conversions and modifications ........................................................................... 15

3.4 Technical data..................................................................................................... 15

3.5 Location requirements......................................................................................... 16

3.6 Structure.............................................................................................................. 16

3.7 Function and system description......................................................................... 17

3.8 LED status light ................................................................................................... 17

3.9 Interfaces ............................................................................................................ 18

4Transport, installation and storage .......................................................... 19

4.1 Introductory notes on safety ................................................................................ 19

4.2 Packing ............................................................................................................... 19

4.3 Transport............................................................................................................. 19

4.4 Delivery ............................................................................................................... 20

4.4.1 Scope of delivery ..................................................................................... 20

4.4.2 Inspection for transport damage .............................................................. 20

4.5 Download app ..................................................................................................... 21

4.6 Storage................................................................................................................ 21

5Commissioning........................................................................................... 22

5.1 Introductory notes on safety ................................................................................ 22

5.2 Installation ........................................................................................................... 22

5.3 Notes on connecting the extender....................................................................... 23

5.4 Connection .......................................................................................................... 24

6Operation..................................................................................................... 31

6.1 Introductory notes on safety ................................................................................ 31