TABLE OF CONTENTS

TABLE OF CONTENTS.................................................................................................................................................1

LASER SAFETY ..........................................................................................................................................................3

INTRODUCTION..........................................................................................................................................................4

Overview..............................................................................................................................................................4

System Configuration..........................................................................................................................................4

LP-4210F™ Data Acquisition Instrument ...........................................................................................................5

Delivery System....................................................................................................................................................7

LaserViewer™ 2010 Software .............................................................................................................................7

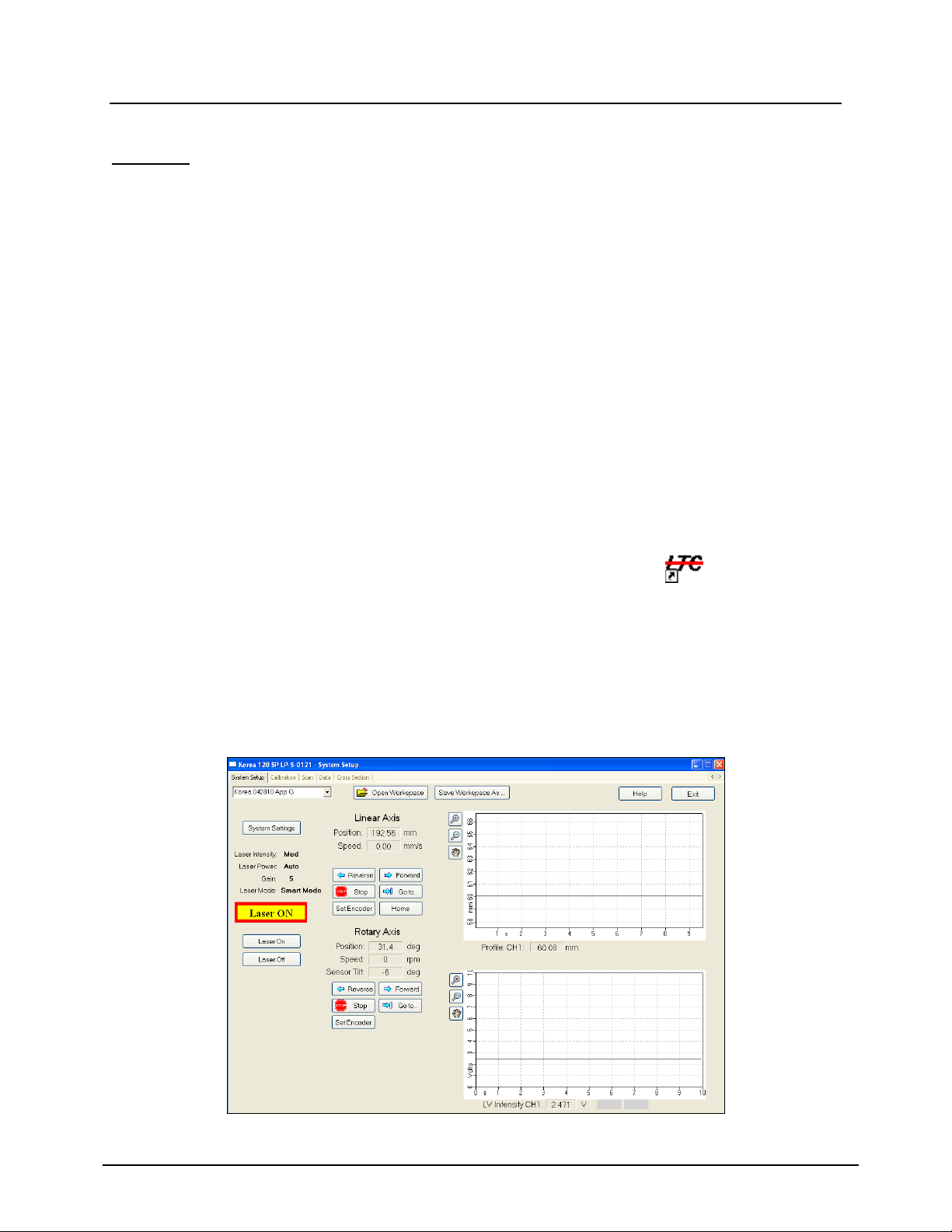

SYSTEM SETUP ..........................................................................................................................................................8

SYSTEM SETTINGS.....................................................................................................................................................9

Laser Power.........................................................................................................................................................9

Automatic.............................................................................................................................................................9

Fixed ....................................................................................................................................................................9

Laser Intensity.....................................................................................................................................................9

Gain .....................................................................................................................................................................9

Null......................................................................................................................................................................9

OPENING AND SAVING WORKSPACES......................................................................................................................10

Opening a Different Workspace .......................................................................................................................10

Saving a Workspace..........................................................................................................................................10

MOTOR AND AXIS CONTROL ...................................................................................................................................11

Driving Motors..................................................................................................................................................11

Moving to a Specified Location ........................................................................................................................11

Stopping Motors ................................................................................................................................................11

Setting Encoder Values.....................................................................................................................................11

SYSTEM CALIBRATION ............................................................................................................................................12

Initializing a Calibration Scan .........................................................................................................................12

If the Calibration Verification Process Passes.................................................................................................12

If the Calibration Process Fails........................................................................................................................13

Calibration Troubleshooting.............................................................................................................................14

SCANNING OPERATION............................................................................................................................................15

Setting the Scan Parameters.............................................................................................................................15

Advanced Scan Parameters................................................................................................................................15

Initializing a Scan .............................................................................................................................................16

VIEWING AND ANALYZING DATA............................................................................................................................17

Viewing Profile Data.........................................................................................................................................17

Opening Data Files............................................................................................................................................17

Data File Header ...............................................................................................................................................17

Color Plot Display .............................................................................................................................................18

Color Palette......................................................................................................................................................19

Changing the Magnification ..............................................................................................................................19

Viewing in 1:1 Aspect Ratio...............................................................................................................................20

Displaying Cross-Sectional Auxiliary Windows ................................................................................................20

Displaying Annotations......................................................................................................................................20

Viewing LaserVideo™ (LVI) Data ...................................................................................................................21

Data Analysis.....................................................................................................................................................22

Applying Processors to a Scan Data File ..........................................................................................................22

Processors..........................................................................................................................................................23

Reading Data Values .........................................................................................................................................25

Making point-to-point measurements.................................................................................................................25

Calculating Area/Diameter Statistics.................................................................................................................25

Viewing Cross Sectional Data...........................................................................................................................26

Selecting the Viewing Position...........................................................................................................................26

Selecting the Reference Radius ..........................................................................................................................27

Measuring the Radius/Diameter ........................................................................................................................27

Measuring Pit Depth..........................................................................................................................................27

Printing and Saving Data .................................................................................................................................28