6

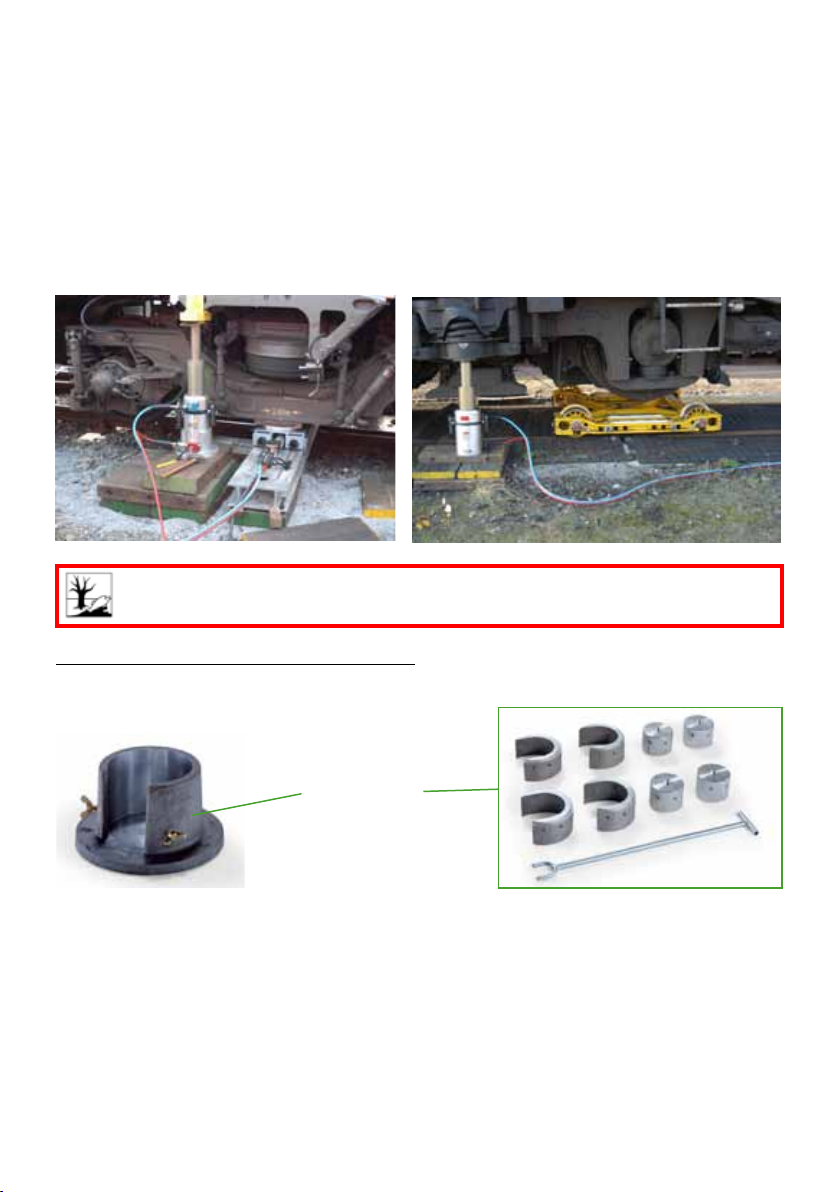

The device is lled with a

hydraulic uid. These hydraulic

uids can be harmful to your

health if swallowed or if their

vapours are inhaled. Direct

contact with the skin should

be avoided for the same

reason. Please also note that

hydraulic uids can also have

an adverse effect on biological

systems.

When working with or storing

the equipment, ensure that the

function and the safety of the

equipment are not impaired by

the effects of extreme external

temperatures and that the

equipment is not damaged in

any way. Please note that the

device can also heat up over a

long period of use.

In the event of malfunctions,

immediately deactivate the

device and secure it. You

should have the malfunction

repaired immediately.

Do not carry out any changes

(additions or conversions) to

the device without obtaining

the prior approval of LUKAS.

Observe all safety and danger

notices on the device and in

the operating instructions.

All safety and danger notices

on the device must be kept

complete and in a legible

condition.

Any mode of operation which

impairs safety and/or stability

of the device is forbidden!

Comply with all stipulated

dates or dates specied in

the operating instructions

pertaining to regular tests /

inspections on the equipment.

Safety devices must never be

disabled!

The maximum permitted

operating pressure noted on

the equipment must not be

exceeded.

Before the device is switched

on / started up, and during its

operation, it must be ensured

that nobody is endangered by

the operation of the device.

Only original LUKAS

accessories and spare parts

may be used for repairs.

Please ensure that, when

working with this equipment

or during transportation of

such, you do not become

entangled in the looped hoses

and trip.

When working in the proximity

of live components and wires,

appropriate steps must be

taken to avoid current ow

or high-voltage discharge

through the device.

The build-up of static

charge with the potential

consequence of spark

formation is to be avoided

when handling the device.