TEST BEFORE

INSTALLING

Our production, packaging and shipping process is accompanied by a rigorous quality control procedure.

All Light Sheets are subjected to a burn in period and are tested before packaging to ensure

operation

of

the

highest

quality.

Due

to

possible

unforeseen

issues

with

shipping

and

handling,

we

advise that all Light Sheets be inspected at time of delivery and dry-t tested for proper illumination

prior to mounting and again before the forward facing material is installed.

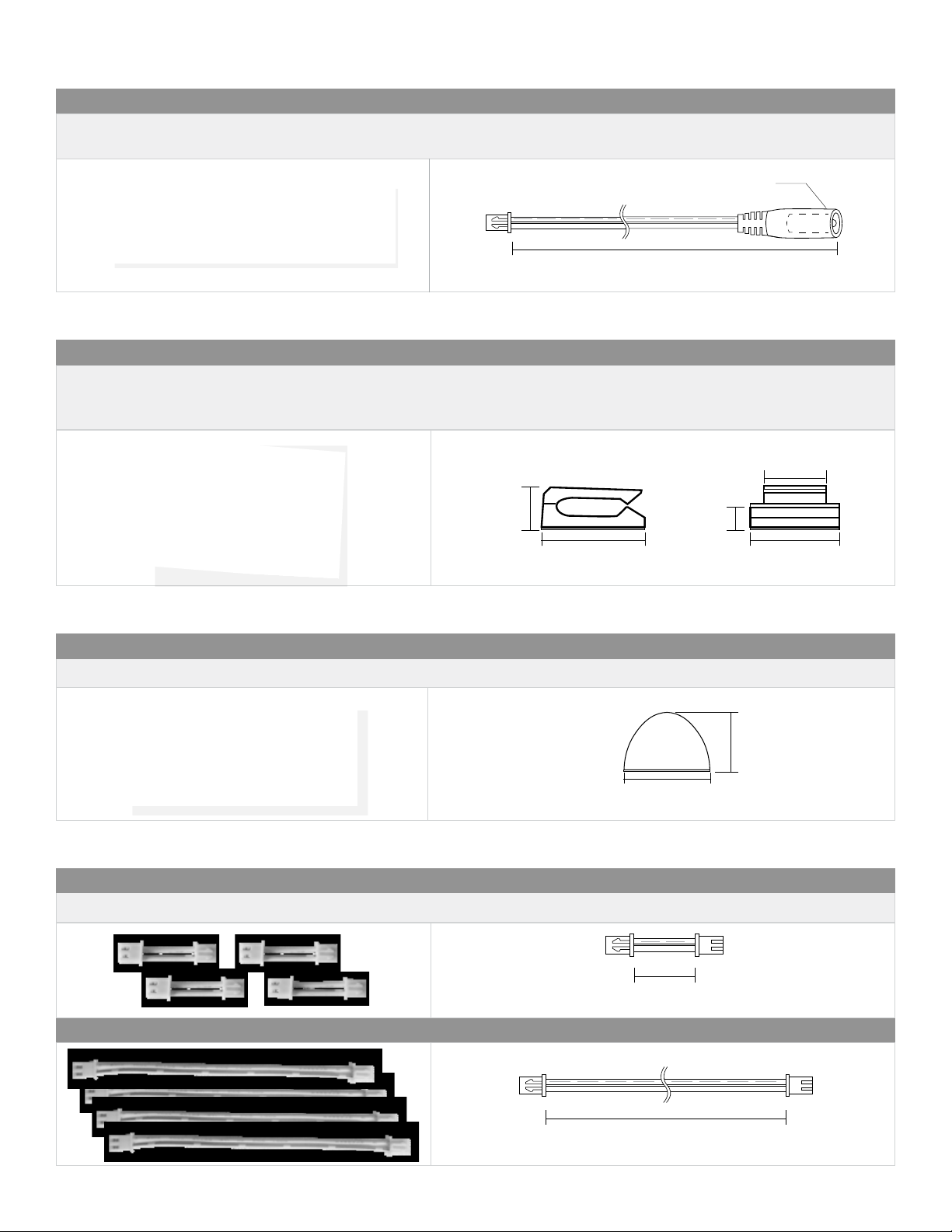

FRAGILE 2-PIN

CONNECTION

BLOCKS

DISCONNECT POWER AT THE SOURCE BEFORE REMOVING ANY 2-PIN CONNECTION BLOCKS.

The

integrated 2-pin connection blocks are made of plastic which can be damaged if made to bear weight.

Use domed spacing bumpers (included) to bear the weight of any forward facing material in horizontal

applications and to act as a safeguard to protect the Light Sheet in vertical applications.

DRILLING

DISCONNECT POWER AT THE SOURCE BEFORE ALTERING THE SHEET IN ANY WAY. Light Sheets

have specic areas where holes can be made in the sheet. The smaller diameter circles on the Light

Sheet (0.12” / 3mm) indicate the maximum diameter of screw or other fastener’s shaft that can be used

without causing damage to the Light Sheet’s power distribution grid. The larger diameter circle (0.24” /

6mm) is the maximum diameter of the screw head that can be used to without causing damage.

INSTALLATION

TEMPERATURE

Due to the characteristics of the 3M adhesive backing, installation environments and locations should

be taken into consideration. Low temperatures can cause longer cure times for permanent adhesion.

STORAGE

STORAGE Store

Light Sheets

in a clean, dry area on a at, horizontal surface. Do not open the anti-static

envelope

until ready to install. Ideal storage conditions: Temperature of 68° – 77°F, 50% humidity.

DO NOT

CONNECT TO AC

POWER

ANY DIRECT CONNECTION OF LIGHT SHEETS TO AC CURRENT WILL DAMAGE THE LEDs.

Be sure to use a UL Listed or UL Recognized Class 2, LPS or LVLE low voltage power supply that conforms

to the voltage requirements of the Light Sheet. This information can be found on the Light

Sheet

and its packaging, as well as the power supply labeling.

PRODUCT HANDLING, INSTALLATION & INTEGRATION ADVISORY

POWER, CONTROL

& WIRING

For optimal power distribution and to minimize voltage drop, it is recommended that multi-strand, high

strand count wiring be used for all low voltage DC connections. Wire gauge should be appropriate based

upon system voltage and wire lengths to further minimize voltage drop. Power supplies, drivers and

controls should be installed in well ventilated enclosures and/or per manufacturers recommendations.

It is the customer’s responsibility to ensure all components and installation practices meet or exceed

local codes and requirements.

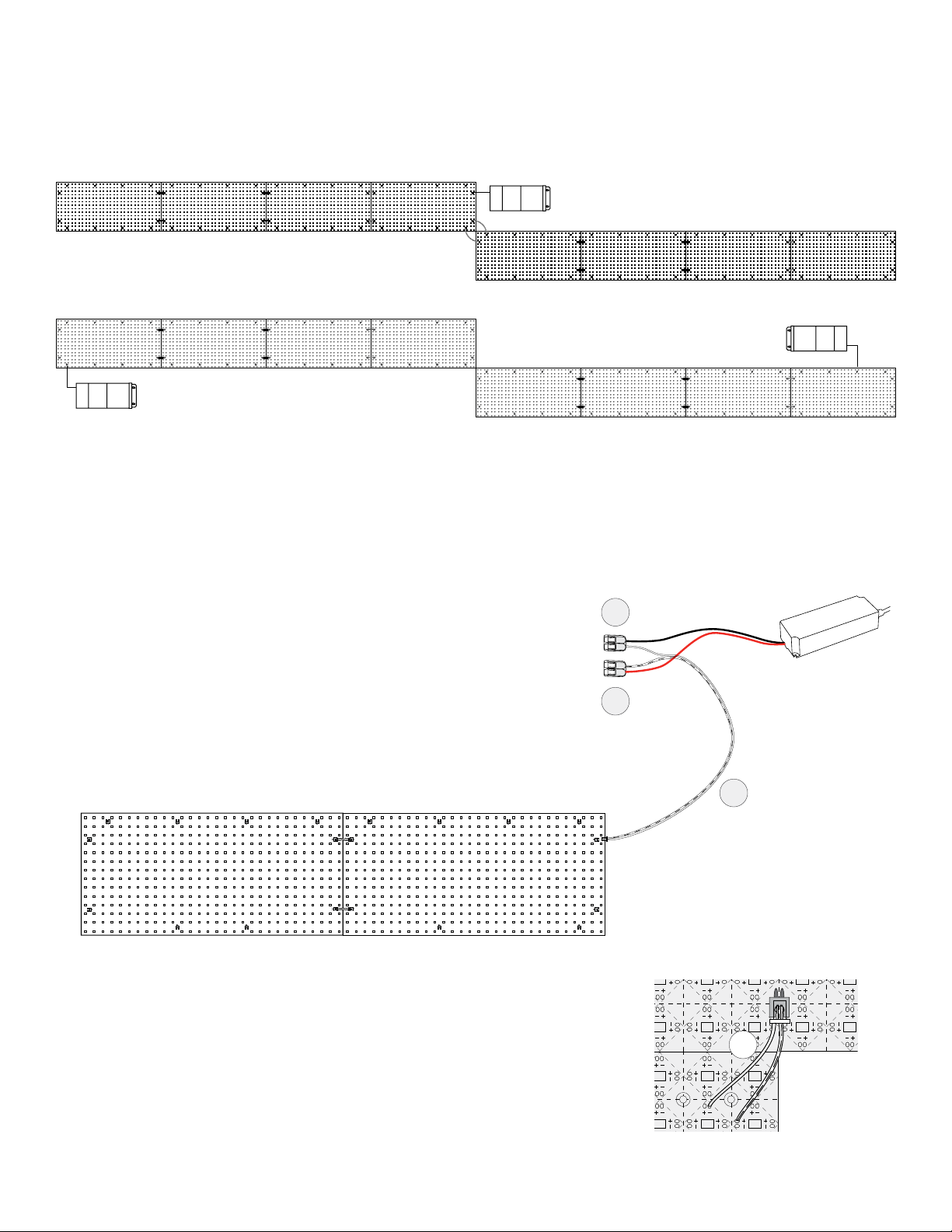

FOLDING &

MINIMUM RADIUS

There is no minimum bending radius for Light Sheets, however a single sheet may not be

folded on itself because this could disrupt the ow of electricity through the folded sheet. Two separate

IP65 sheets may be attached back-to-back since the 3M adhesive backing will act as non-conductive

barrier. Light Sheets are not recommended for applications where a radius of less than 2” exists.

CUTTING

DISCONNECT

POWER

AT

THE

SOURCE

BEFORE

ALTERING

THE

SHEET

IN

ANY

WAY.

NEVER

CUT

LIGHT SHEET WHILE POWERED. Field cutting of the Light Sheet does not void UL Listing. LEDs

can lose

input power if cut lines are not followed. Avoid cut edge contact with any conductive material(s),

including other cut edges of Light Sheets. See also Wet Location Use below.

SOLDERING

DISCONNECT POWER AT THE SOURCE BEFORE ALTERING THE SHEET IN ANY WAY.

Solder sheets or

strips of Light Sheets together or solder power input(s) to Light Sheets. The Light Sheet’s copper pads

are

engineered to handle 4A of load and polarity is noted by the + and - next to each copper pad. Use

20AWG

stranded copper wire for up to 4A of load and follow

electronics

soldering best practices.

FASTENING

USE PAN HEAD, DOMED, OR ROUND HEAD FASTENERS, NOT TAPERED SCREWS. Never screw the

fastener so much that it deforms the Light Sheet. Only penetrate the Light Sheet at the concentric circles

marked on the sheet (see Drilling above for screw size limitations). For suspended applications, use

mechanical fasteners with an appropriate spacing to avoid sagging.

WET

LOCATION USE

Light Sheets are rated IP65. This rating is total protection against dust ingress as well as water

projected by a nozzle against the enclosure from any direction for a limited time and may be used in wet

locations, but not where standing water can accumulate. Cut edges of IP65 can optionally be sealed from

moisture with an RTV Silicone Sealant or conformal coating.

IP65