lumiglas®

lumiglas

Installation and Operating Instructions for Lumiglas luminaires

Lumiglas luminaire model USL06-Ex

• Important note:

Sightglass luminaires are specifically designed and exclusively

intended for mounting onto flanged sightglass fittings.

Under no circumstances may luminaires be substituted for

cover flange or complete sightglass units or in any other way

be used as lids or covers for vessel openings.

Luminaires for Ex hazardous areas may only be installed and

serviced by suitably qualified personnel duly authorized for

those tasks.

EC type test certificate contents to be noted.

• General operating conditions:

- independent of vessel pressure/vacuum

- approved for use in Ex Zones 1 & 2 and 21 and 22

- approved for use at temperatures up to 60° C or 40° C

depending on lamp power (see identity plate)

• Electrical data – general:

- Voltage, power, temperature class and protection rating

are shown on identity label

- Ex approval in accordance with type test certificate

PTB 99 ATEX 1157

II 2G EEx d (e) IIC T3, T4, T6, or 120° C;

EXAM BVS 06 ATEX E009

II 2D IP 67 T 195° C or T 130° C

- Version fitted with integral transformer is protected by

PTC; fuse exchange not needed

- Observance of data given in EC type test certificate

imperative!

- Power supply: depending on components fitted – AC or DC

(Warning: only AC may be used with luminaires fitted with

integral transformers or high voltage timer)

-Warning: excessive voltage will shorten lamp life!

- 10% tolerance in voltage is approved

• Electrical connection:

a) Version I (with cable tail)

- the electric cable is fitted ready for use at manufacturers

works.

- the external safety conductor terminal (item 1) must be

connected to a separate grounding point on the plant

- the cable must be supported within 1 m of entry gland.

-Warning: when changing cable (e.g. for another length)

the internal wiring must be disconnected before

unscrewing the cable entry gland

b) Version II (with terminal box)

- select a cable corresponding to cable entry gland M20 x 1.5

and temperature rating according to type plate

- remove terminal box lid. Loosen screws (and anti twist

tabs) on cable pull-out preventer clamp on cable gland

assembly. Feed in cable and retighten screws

- connect cable cores to Ex terminal block (6); safety

core to terminal – internal (5). External ground terminal (1)

must be connected to separate ground point on plant

- fit terminal box cover gasket and refit cover

• Lamp Exchange:

- switch off power

- allow sufficient time to cool as indicated on identity plate

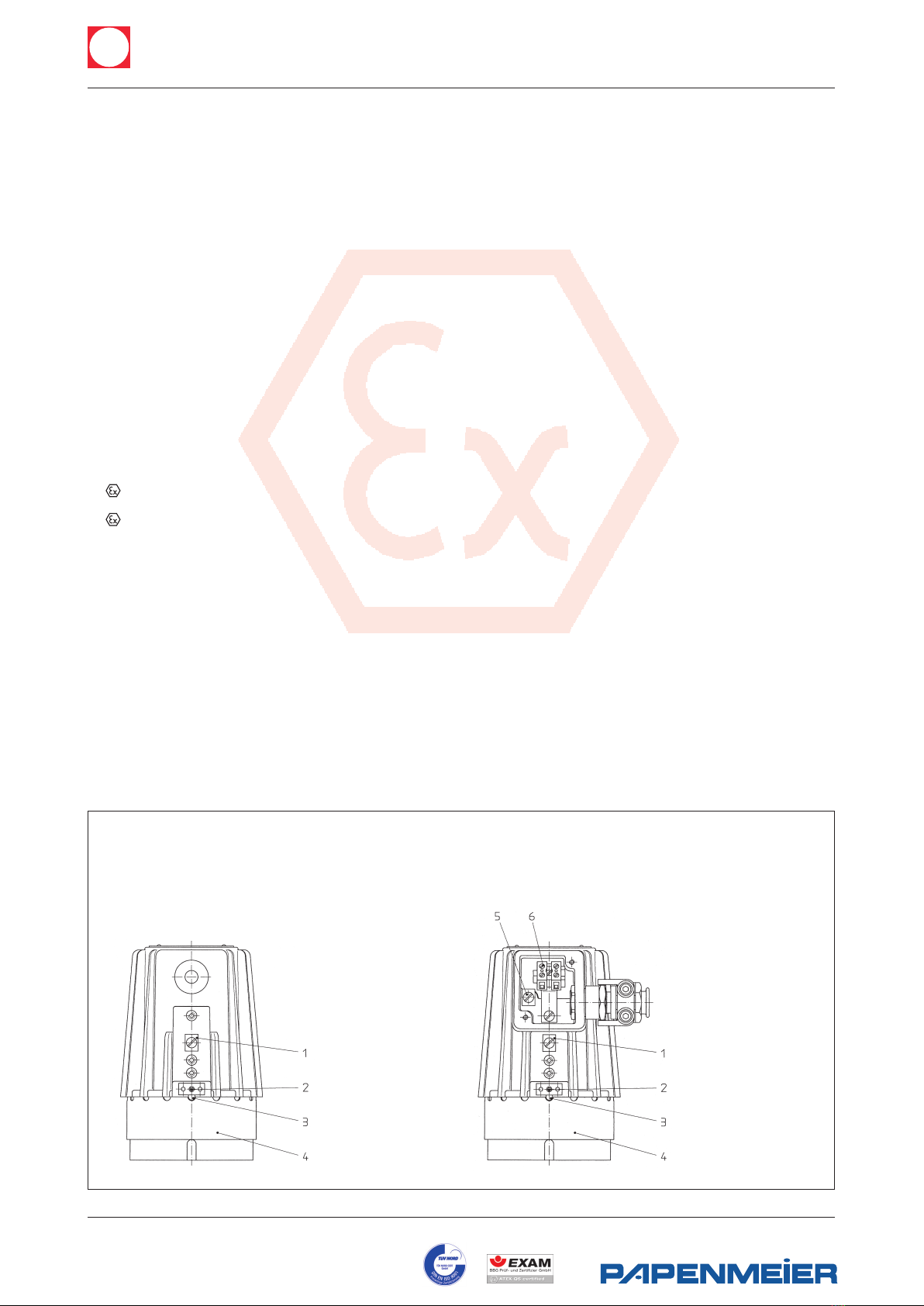

- loosen socket screw (2) which releases locking tab (3) to

screwed lens ring (4)

- unscrew lens ring (4) but only with special claw spanner

- withdraw defective lamp; 2 pin is pulled out;

GZ 10 bayonet type twisted and pulled out

- holding new lamp (use only genuine replacement part) by

its protective material (never with bare fingers) insert into

socket, pushing in carefully in case of 2 pin; twist and push

in case of bayonet type (ensure correct seating)

- refit lens ring (4) and screw in until tight (compression of

O ring seal)

- safety locking tab (3) must engage in appropriate notch so

that lens ring (4) is locked in position

- retighten locking screw (2)

- reconnect power

• Warning:

When changing lamps ensure that the light beam remains

evenly distributed over the lamp glass, as designed. On no

account should a “hot spot” be allowed to develop

externally to the luminaire (e.g. caused by lamp mis-

positioning or as a result of lamp condition)

1 Safety/ground

terminal – external

2 Locking screw

3 Safety locking tab

4 Screwed lens ring

1 Safety/ground

terminal – external

2 Locking screw

3 Safety locking tab

4 Screwed lens ring

5 Safety/ground

terminal – internal

6 Ex terminal block

• Version I (with cable tail EEx d)

- cable entry gland; with pressure tight resin cast

connecting cable (Sinotherm 110 H05GG-F 3G 1.5 mm2)

- safety/ground conductor terminal fitted to luminaire

body internally; additional terminal fitted to outside

of body

• Version II (with terminal box EEx de)

- cable entry gland: M20 x 1.5

F.H.Papenmeier GmbH & Co. KG · division Lumiglas

Talweg 2 · 58239 Schwerte · GERMANY

phone: +49-2304/205 0 · fax: +49-23 04/205 206

e-mail: info.lumi@papenmeier.de

www.lumiglas.de