1GENERAL

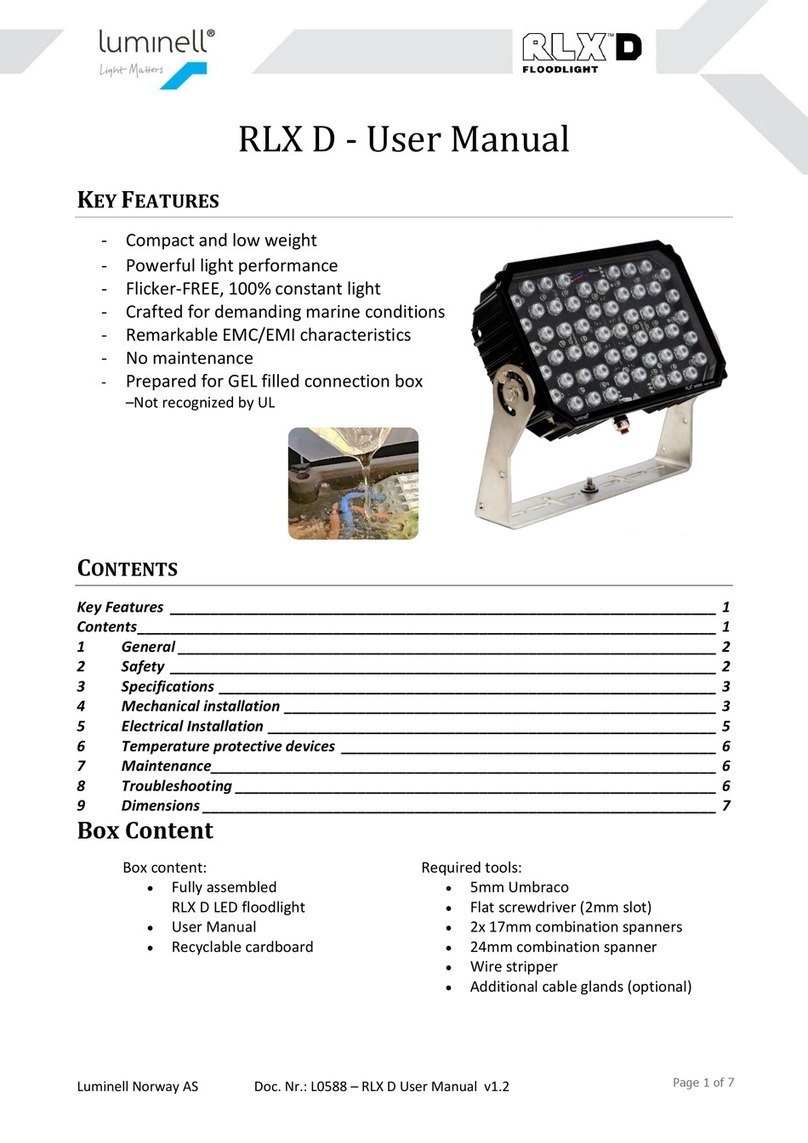

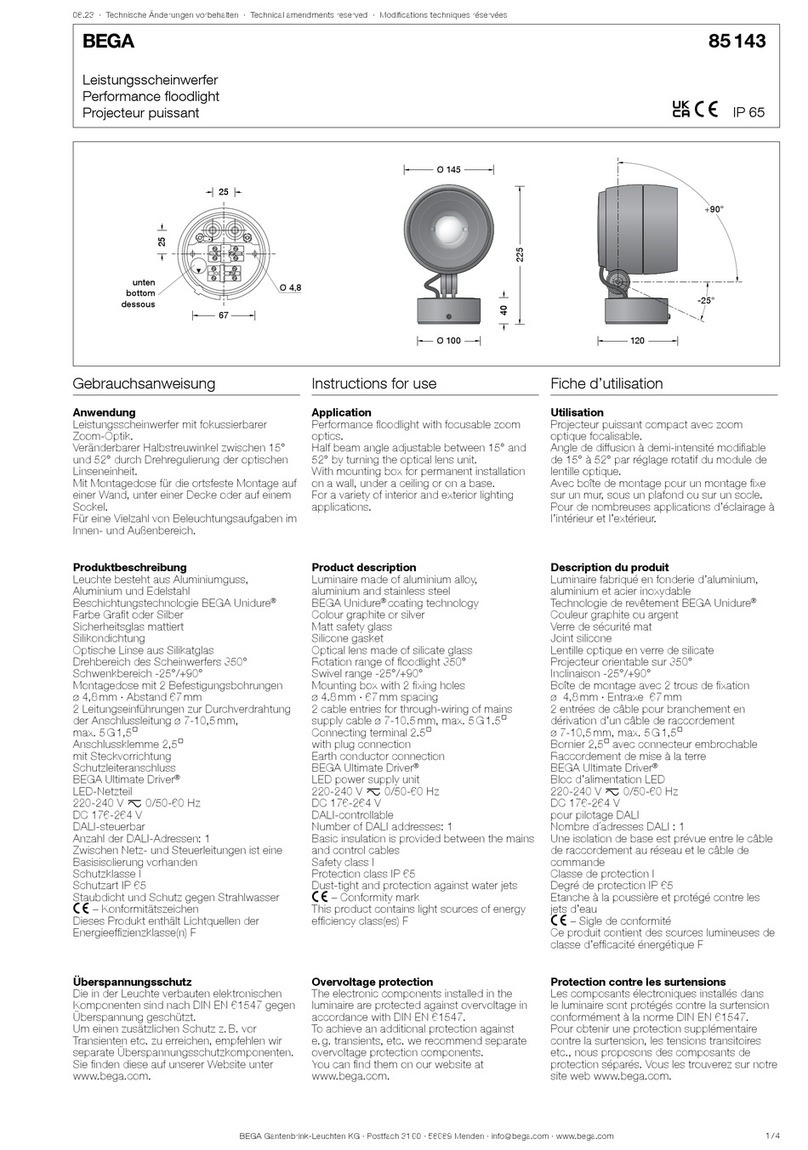

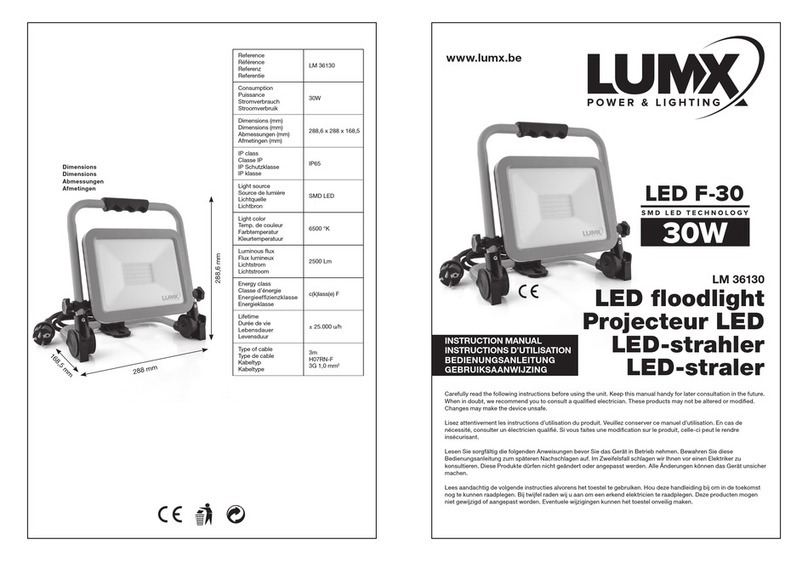

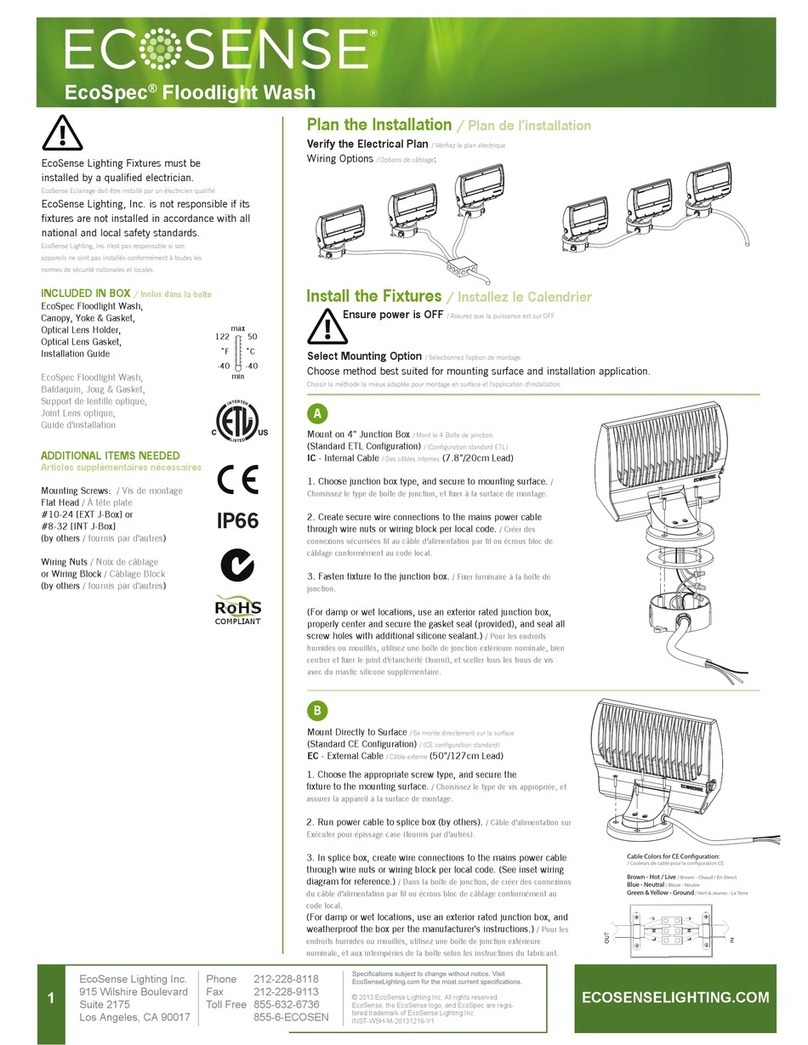

The RLX CxZ1.21 is a compact and solid LED floodlight created to last in very harsh and corrosive

environments. It is designed to be used both in gas and dust environments, zones 1, 2, 21 and 22.

Read this user guide to get the most out of your RLX CxZ1.21 LED floodlight and help it to maximize its

potential for your application.

2SAFETY

Inappropriate or unauthorized use or failure to comply with the information contained in these

instructions, voids any warranty and may invalidate the certificate. Modifications or changes to the

equipment are not allowed.

The following must be observed:

•national safety regulations

•national workplace health and safety regulations

•national installation and set-up regulations

•generally accepted engineering standards

•the safety information contained in these operating instructions

•the data and rated operating conditions

•disposal of waste, parts or floodlight in accordance with national regulations

•the ATEX or IECEx certificate

•the equipment is suitable for harmful or corrosive chemicals that may be

present

For the installation and operation of explosion-protected equipment, the

recognized rules of technology in accordance with EN60079-14 “Configuring and

selection”, and EN60079-17 “Test and maintenance”, and the accompanying

installation and operating instructions must be observed. Luminell reserves the

right to make technical changes to the product without notice.

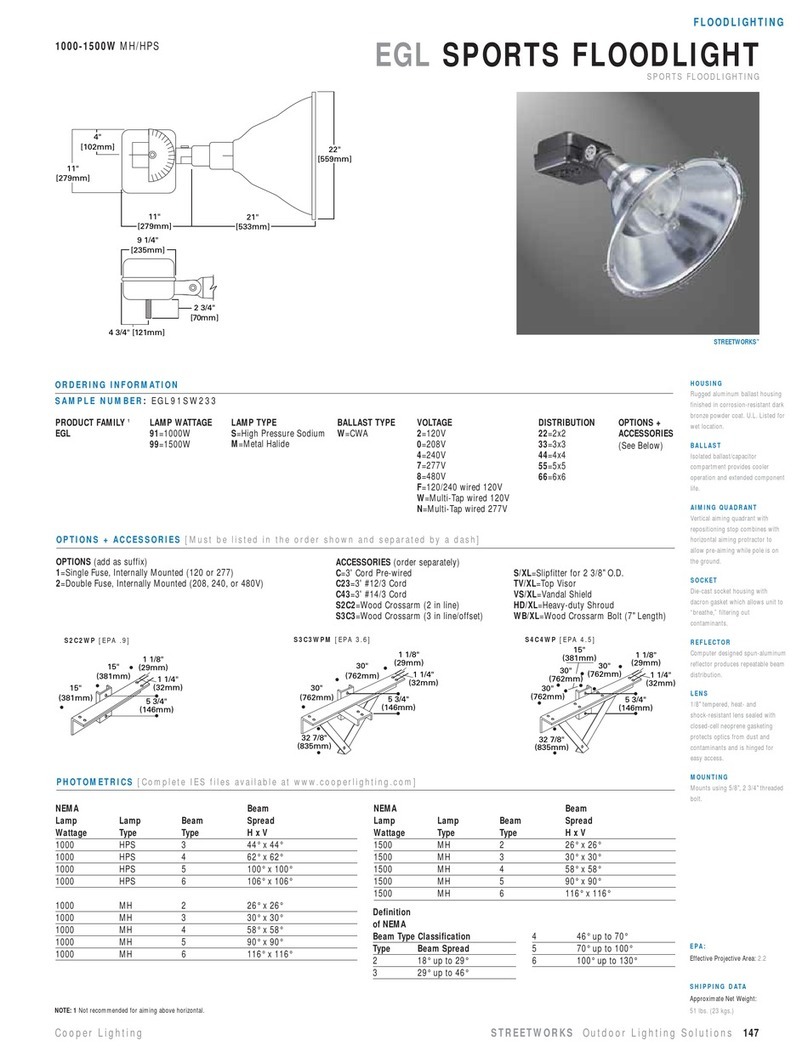

3TYPE OVERVIEW