A-3

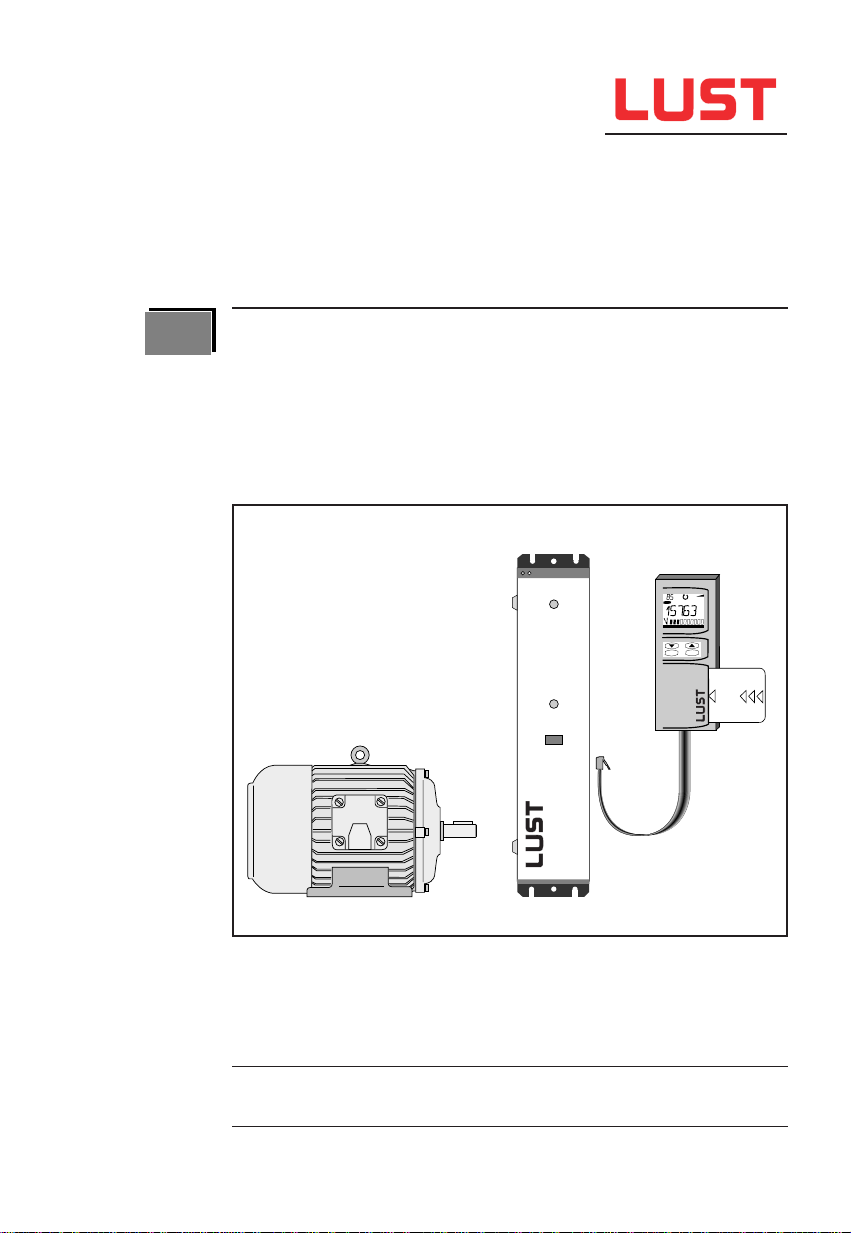

Directly to your goal

A Useful information on the Operating Manual......... A-2

A Directly to your goal .................................................... A-3

A.1 Safety instructions....................................................... A-5

A.2 Intended use ............................................................... A-5

A.3 Design ......................................................................... A-7

A.4 Manufacturer’s declaration for frequency inverter ....... A-8

A.5 VF1000M with CE - acceptance test........................... A-10

A.6 Instructions for correct EMC installation...................... A-12

1 Technical data ........................................................... 1-1

1.1 Assembly and layout plan ........................................... 1-1

1.2 Data table.................................................................... 1-2

1.3 Scale drawing.............................................................. 1-3

1.4 Device assembly ......................................................... 1-4

2 Electrical connections.............................................. 2-1

2.1 Connection plan .......................................................... 2-1

2.2 Fault transmission/fault resistance.(EMC)....................2-3

2.3 Power connections ...................................................... 2-4

2.3.1 Mains connection ........................................................ 2-4

2.3.2 Motor connection......................................................... 2-5

2.3.3 Braking chopper (BR1)................................................ 2-5

2.3.4 Motor temperature monitoring

(Design PTC/PT1)....................................................... 2-6

2.4 Control connections..................................................... 2-7

2.4.1 Specification................................................................ 2-7

2.4.2 Function of the reference input FSINA........................ 2-8

2.4.3 Control functions with STR/STL .................................. 2-11

2.4.4 Control function via S1IND/S2IND/S3IND................... 2-12

2.4.5 MOP function with S1IND/S2IND................................ 2-14

2.4.6 Signal outputs ............................................................. 2-18

2.4.7 LUSTBUS connection (Design C9, C12) ........................ 2-20

2.4.8 INTERBUS-S connection (Design C8)............................. 2-21

2.4.9 CAN-Bus connnection (Design C2)............................. 2-22

3 Operating and error diagnosis ................................ 3-1

3.1 Display ........................................................................ 3-1

3.2 Warning messages...................................................... 3-1

3.3 Error messages........................................................... 3-2

3.4 Motor/inverter-overload protection (I *t monitoring) .... 3-3