MM102225V1, Rev. B

3

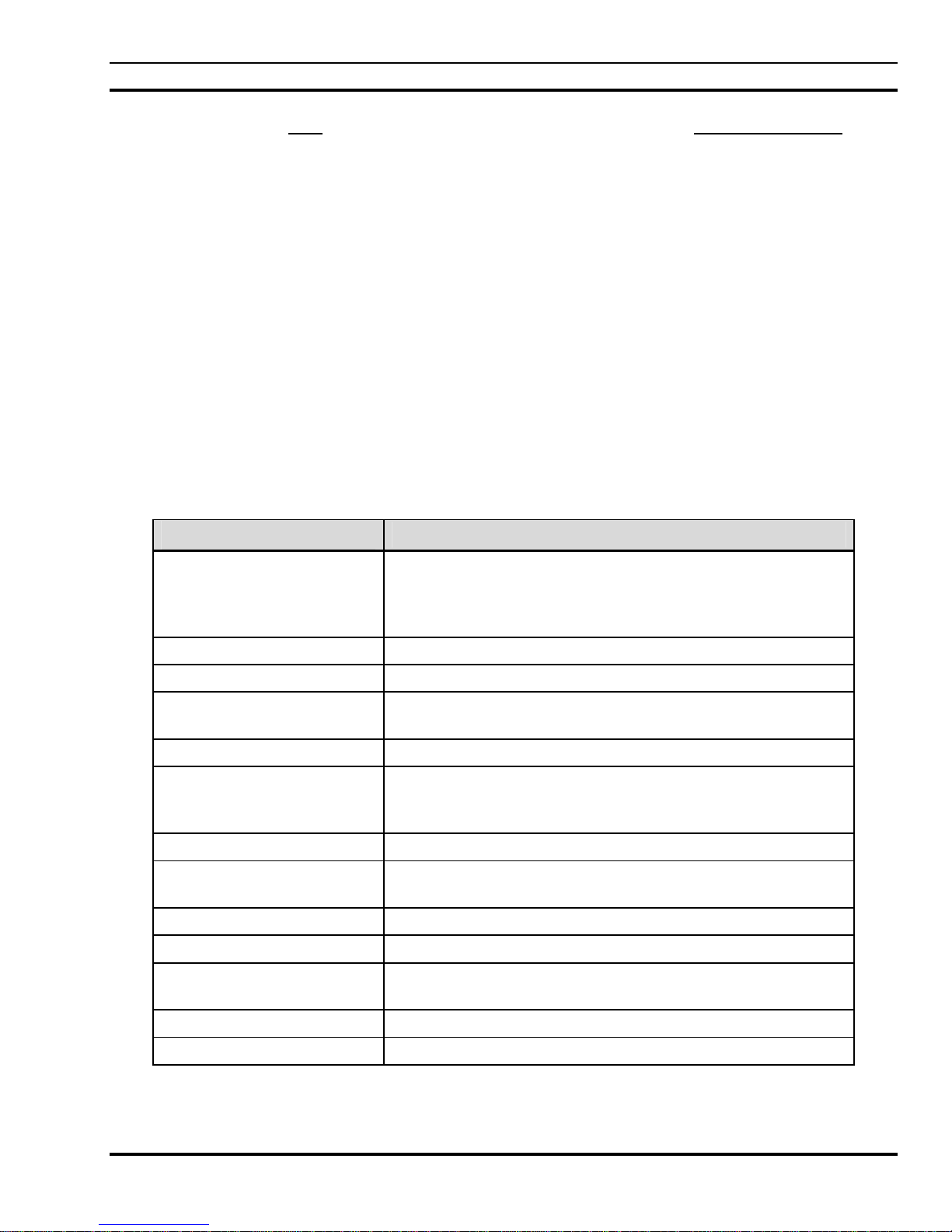

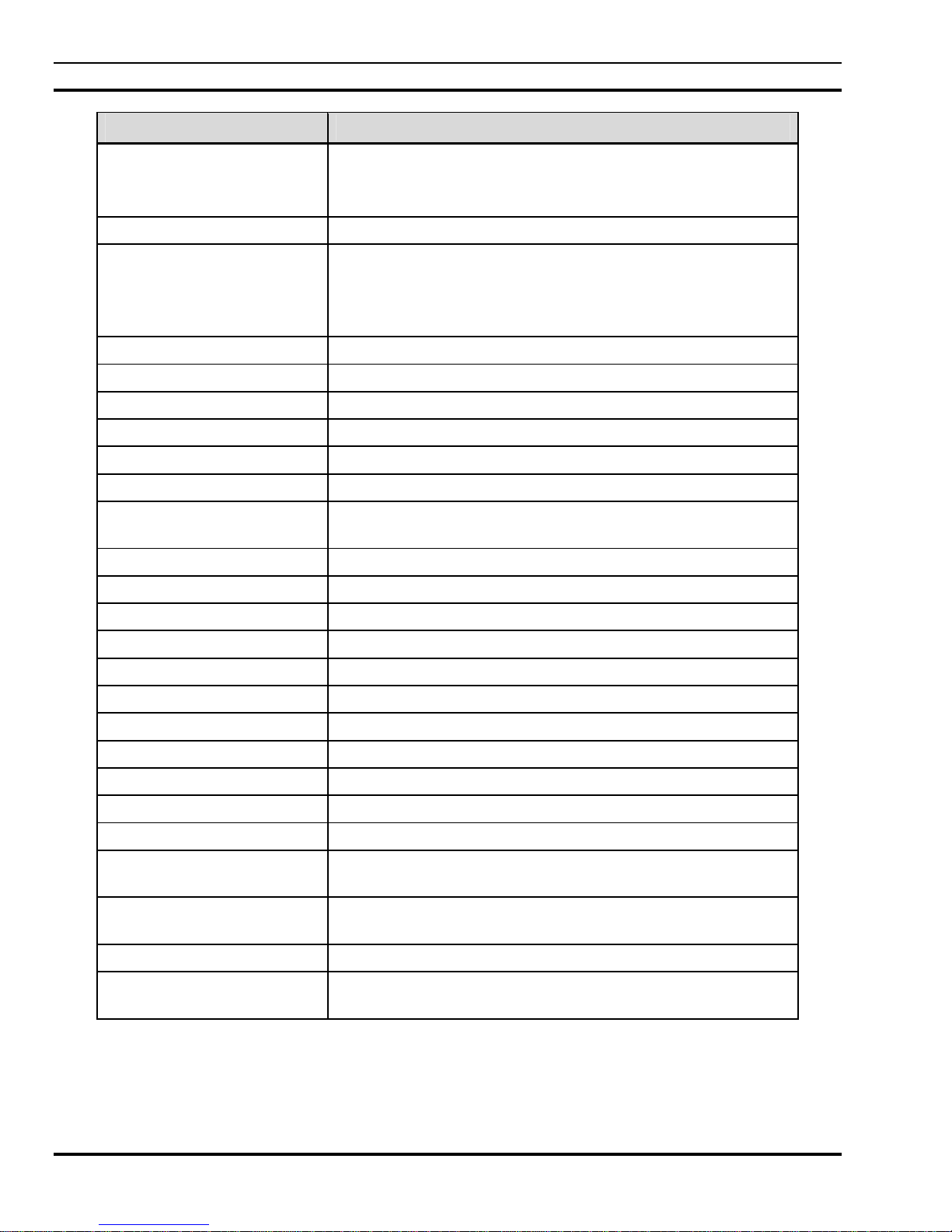

TABLE OF CONTENTS

Page

1.0 GENERAL INFORMATION.............................................................................................................................6

1.1. INTRODUCTION.............................................................................................................................................6

1.2. REFERENCE MATERIAL...............................................................................................................................6

1.3. TOOLS AND TEST EQUIPMENT...................................................................................................................7

1.4. TOOLS REQUIRED FOR SPECIFIC TASK....................................................................................................9

1.5. SAFETY INFORMATION ...............................................................................................................................9

1.6. SAFETY SYMBOLS ......................................................................................................................................11

1.7. OPENSKY BASE STATION EQUIPMENT SPECIFICATION (GENERAL)....................................................12

2.0 SITE PREPARATION......................................................................................................................................13

2.1 INTRODUCTION...........................................................................................................................................13

2.2 ANTENNA SYSTEM .....................................................................................................................................13

2.2.1 Antenna Mounting ...................................................................................................................................13

2.2.2 Transmission Lines..................................................................................................................................13

2.3 TOWER TOP AMPLIFIER.............................................................................................................................15

2.4 SITE REQUIREMENTS.................................................................................................................................15

2.4.1 Floor Plan ...............................................................................................................................................15

2.4.2 Operating Environment...........................................................................................................................15

2.4.3 Electrical Power......................................................................................................................................16

2.4.4 Equipment Room Grounding...................................................................................................................16

2.5 ANTENNA SYSTEM QUALITY AUDIT......................................................................................................16

3.0 BASE STATION INSTALLATION................................................................................................................18

3.1 BEFORE INSTALLATION OCCURS ...........................................................................................................18

3.2 BASICS...........................................................................................................................................................18

3.3 SECURING EQUIPMENT RACKS TO THE FLOOR...................................................................................19

3.4 CABLING EQUIPMENT RACK COMPONENTS........................................................................................22

3.4.1 Interrack Cable Connections...................................................................................................................23

3.4.2 Connecting Power Source and External Equipment................................................................................27

3.4.3 Connect Cabling for the Power Source...................................................................................................28

3.4.4 Connect Grounding Cables to Equipment Racks.....................................................................................30

3.4.5 Connect Antenna Cables to Equipment Racks.........................................................................................31

3.4.6 Connect the T1 Network ..........................................................................................................................32

3.4.7 Site Clean Up...........................................................................................................................................32

3.5 COMPLETING THE INSTALLATION.........................................................................................................32

4.0 SITE TEST PROCEDURES ............................................................................................................................33

4.1 PURPOSE AND SCOPE.................................................................................................................................33

4.2 OVERVIEW OF OPENSKY BASE SITE EQUIPMENT...............................................................................34

4.3 TEST METHODOLOGY................................................................................................................................34

4.4 PREPARATION..............................................................................................................................................35

4.5 RECORDING TEST RESULTS......................................................................................................................35

4.6 BASE SITE BLOCK DIAGRAM....................................................................................................................35

4.7 INSPECTION..................................................................................................................................................36

4.7.1 Pre-test Inspection...................................................................................................................................36

4.7.2 Interrack Cabling ....................................................................................................................................37

4.7.3 New Cabling............................................................................................................................................39

5.0 EQUIPMENT CONFIGURATION.................................................................................................................42

6.0 PERFORMANCE TESTING...........................................................................................................................43

6.1 ANALOG RECEIVE TESTS (MANDATORY).............................................................................................43