Fokker DVIII 55” Page 5

Copyright© 2006-11 M. K. Bengtson All Rights Reserved Rev 07/11

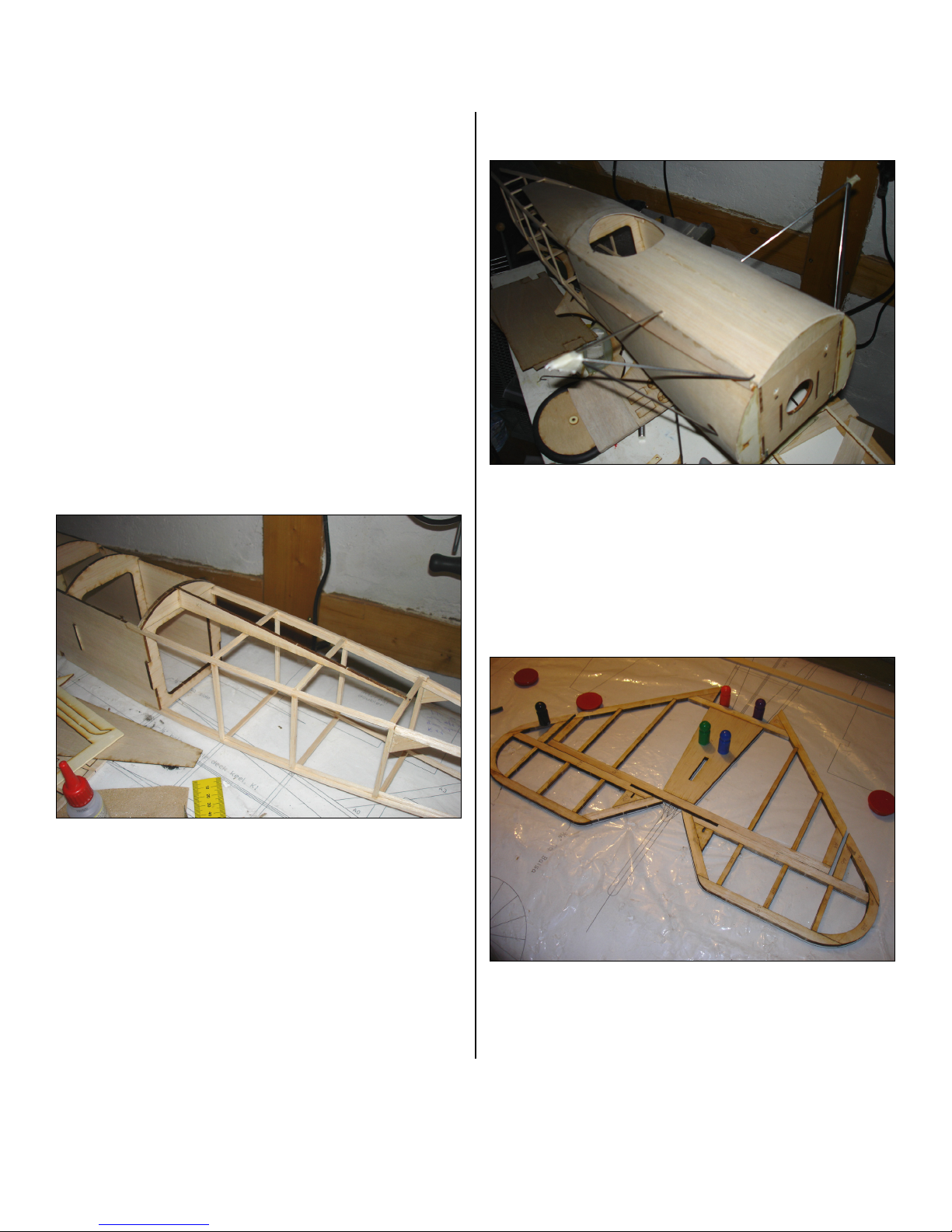

reinforcing hubs are provided that are to slip over the brass

tubing as shown. Next, CA glue the neoprene cording together to

from a “tire”. Use thin CA sparingly as the CA bonds very

aggressively to the rubber. Press the CA wetted ends together for

an instant bond. The best way to align the ends is to glue them

while they are in place on the wheel. Then attach the tires to the

wheels and CA in place. A thin bead of CA around the rim makes

for a secure tire.

Wheel Hubs

Paper cones are cut out. Use a ball point pen to score each line

on the back to make an impression of “spokes” It is helpful to do

this operation on a paper tablet so that the pen makes a good

crease. Fold the paper along the crease lines to exaggerate the

raised lines. One of the sections forming a wedge is cut out.

Make cuts to the center of the circle along a pair of the spokes.

Close the paper cut-out to form a cone and tape the joint inside

the cone.

The inside cones may now be attached to the wheels. The

outside cones may be attached at this point if wheel collars are to

be used. Alternatively, after installing the wheels on the landing

gear, a washer may be soldered to hold the wheel in place and

then the cone is attached. This method makes a very nice scale

appearance.

INSTALLING THE RADIO CONTROL GEAR

Aileron Servos

Aileron servos are mounted in wing and attached with short

threaded rods to the ailerons. Use a “Y” wiring harness connector

to wire the servos to a single radio connection. (If differential

aileron throws are desired, rotate each servo horn forward about

20 degrees, while maintaining the neutral position of the aileron.

This should counter any adverse aileron yaw.)

Battery Tray

After all the above has been placed, mount the battery tray made

from 1/8” balsa and use the battery position to balance the model

as shown on the plan.

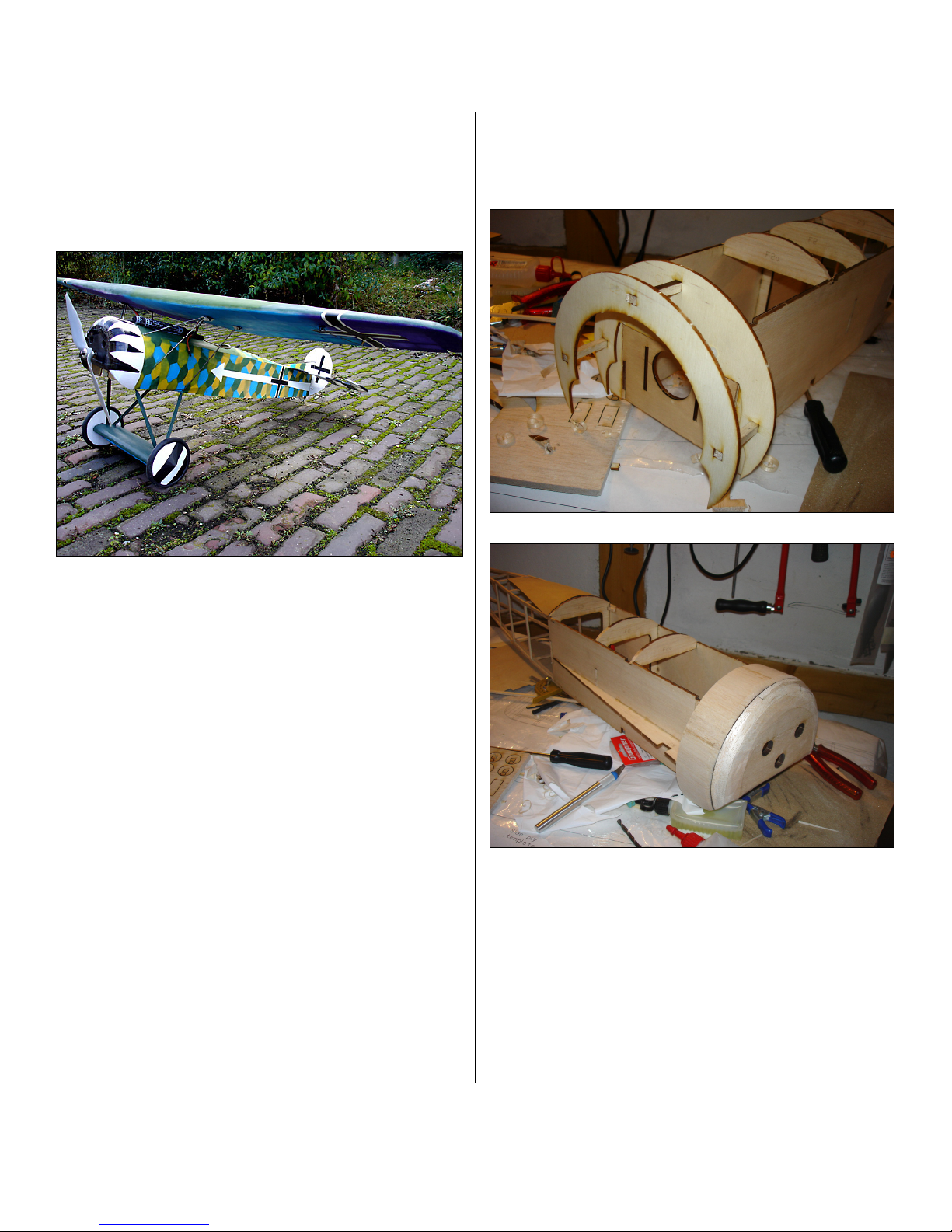

ASSEMBLY

Wing

The wing is attached to the fuselage through the cabane struts.

These are made from 1/16” music wire and are formed using the

markings on the plan as a guide. Saddle clamp style straps are

used to serve as attachment points. They can be commercial

products or made from scrap tin or brass.

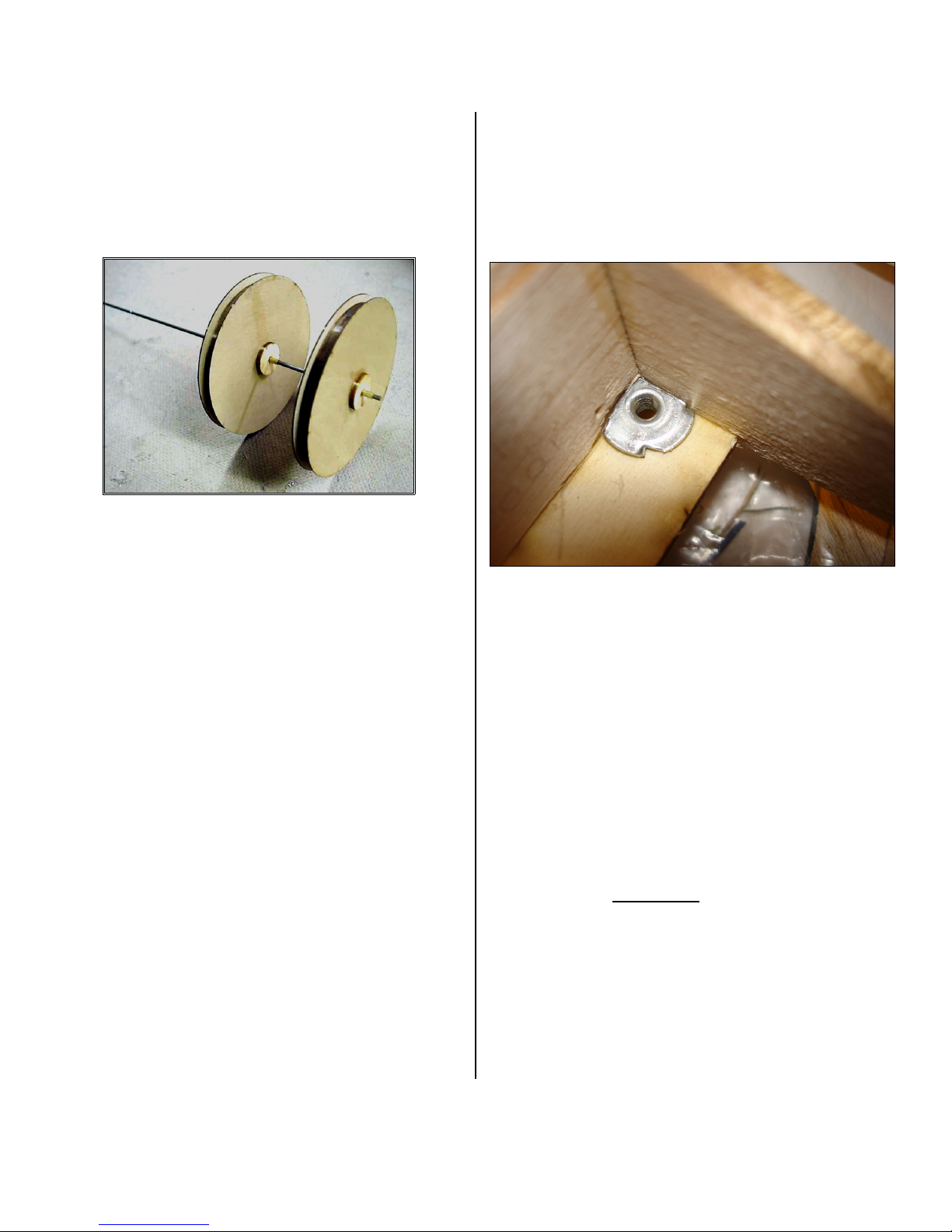

Use 4-40 bolts to secure the wing into the blind nuts embedded in

the ply mounts inside the wing.

Wing Attachment Construction Detail

Fitting Tail Surfaces

Attach the elevator to the horizontal stabilizer.

The horizontal stabilizer and elevator are glued onto the fuselage

first and then the rudder. The rudder should be securely attached

to the fuselage as the area is relatively small. Pinning CA hinges

is recommended.

Adding Control Horns On The Pushrod Ends

Slip the control horns onto the wire pushrod ends and, with both

the servos and the control surfaces centered, glue the horns into

their slots. Some prefer to delay adding the rudder until the

elevator control horn is secure. Then add the rudder and it's

control horn. It makes the job a bit easier.

Use 4-40 bolts to attach the cowl to the firewall 4-40 blind nuts.

Windsock Datafiles “Fokker DVIII“ publication has details on

placement and markings. Available at

http://www.aeroplanebooks.com/

Battery hatch

The 1/32” plywood battery hatch is covered in covering material

after 1/8” sq. balsa reinforcement strips are attached.

Balsa Pilot figure

Assemble fill with foam and paint