9

The manufacturer’s guarantee is valid for 12 months after the delivery date of the

equipment and is limited to the replacement of parts that are to the incontrovertible

judgement of the manufacturer defective due to materials used or to manufacturing .

La guarantee is always and only valid for goods delivered ex works and any other kinds of

compensation, besides the description in the above point, are not considered.

The guarantee is not valid and the manufacturer can be exempted from any responsibility if:

xThe user tampers, without prior written authorisation from the manufacturer, with any

parts or accessories of the appliance itself,

x Damage is caused by misuse of the equipment or by failure to comply with the operating

regulations and guidelines,

x Damage is caused by neglecting to apply the maintenance instructions.

x Operation is contrary to specific directives,

x It has been badly installed,

x electric power supply failures occur,

x The instructions given are not heeded even in part.

x Replacement of any parts or components must always be previously authorised by the

manufacturer.

The guarantee does not cover the electric parts of the machine.

The law court of PADOVA ITALY is responsible for any litigation.

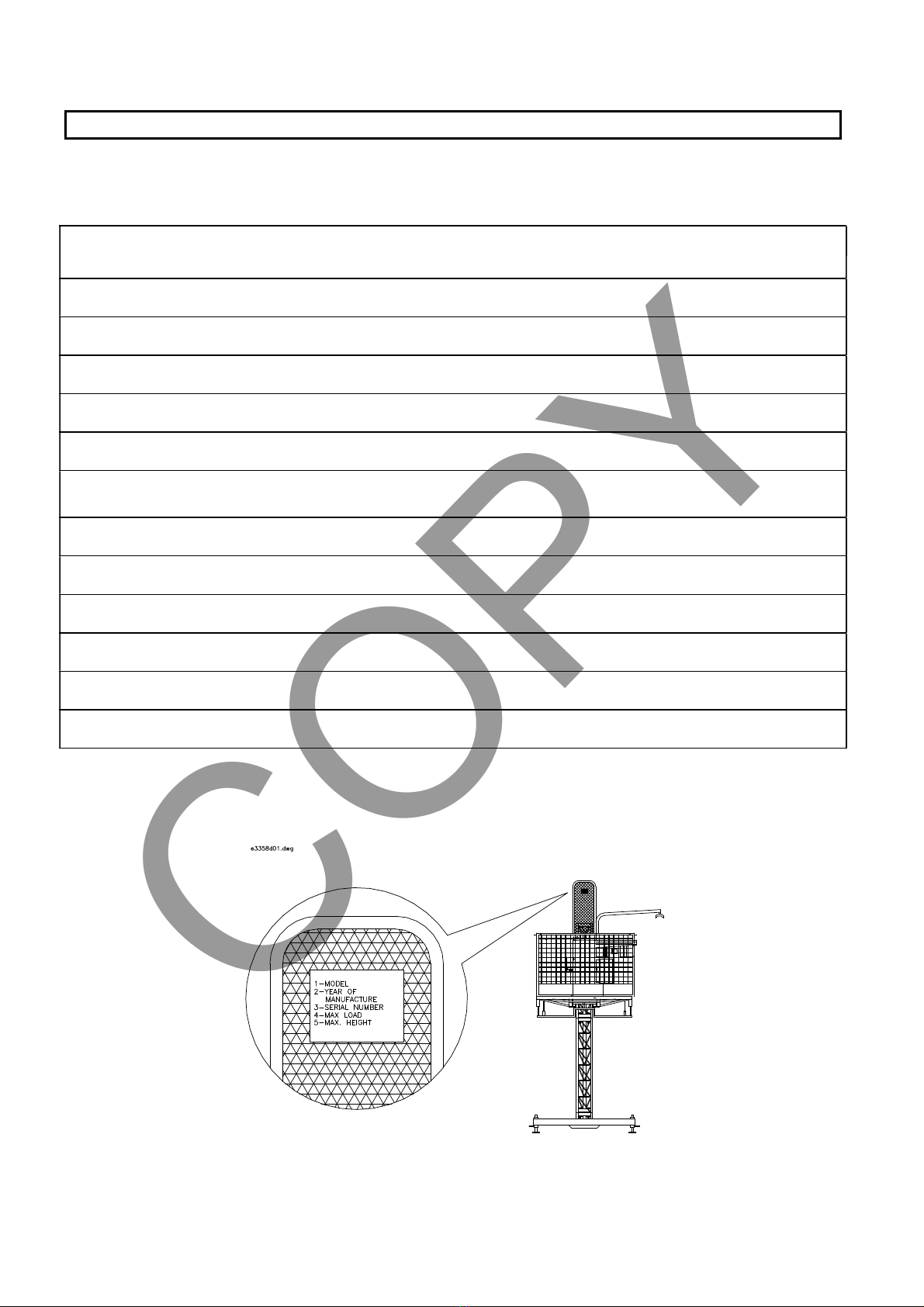

6. HOW TO CONSULT THE MANUAL

The operating and maintenance manual is an integral part of the machine.

Before commencing any installation jobs and machine operation the operator must

carefully read the text with particular regard to all operational safety regulations and

guidelines.

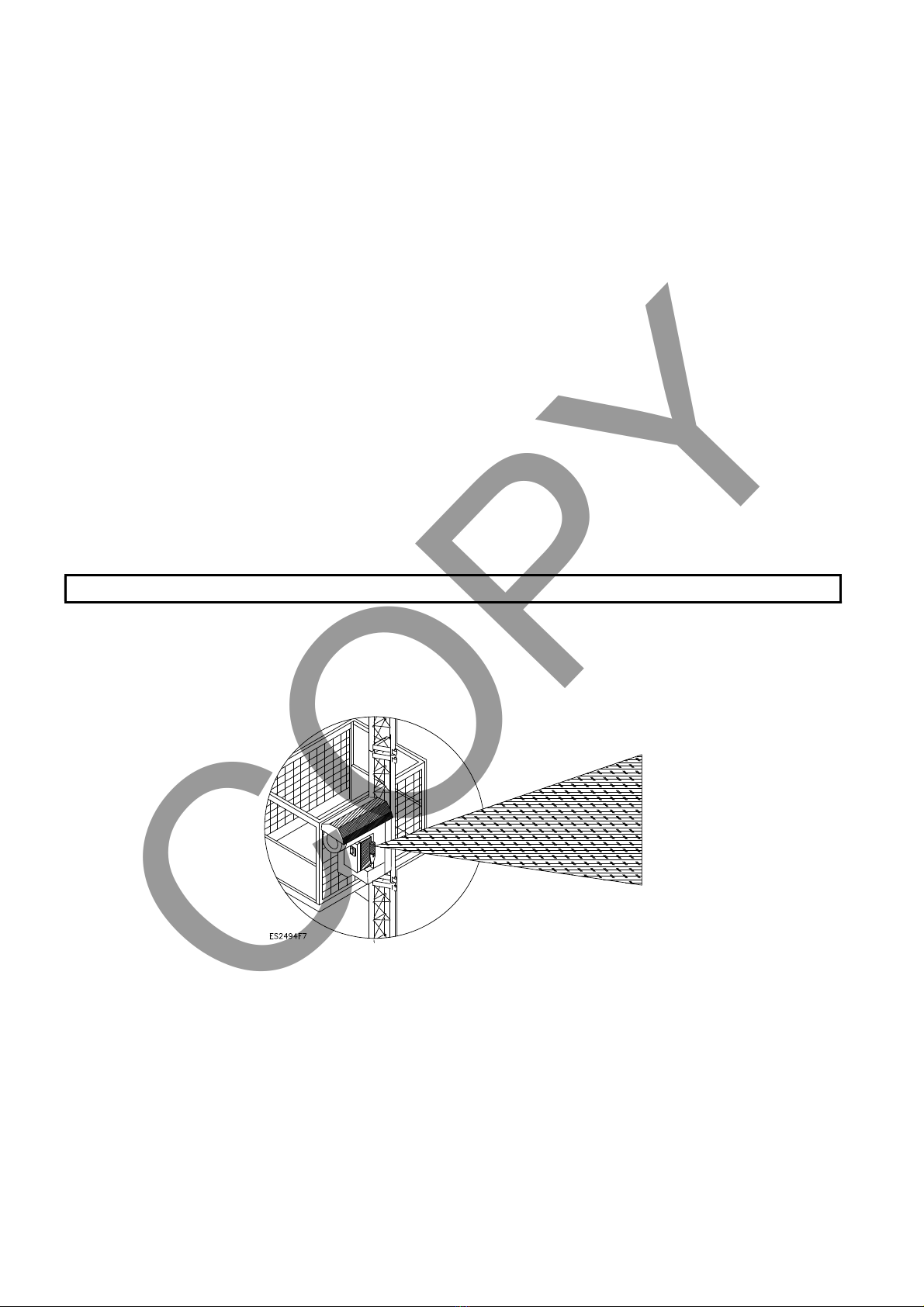

This manual (or an integral copy of it) must always be on the machine so that the

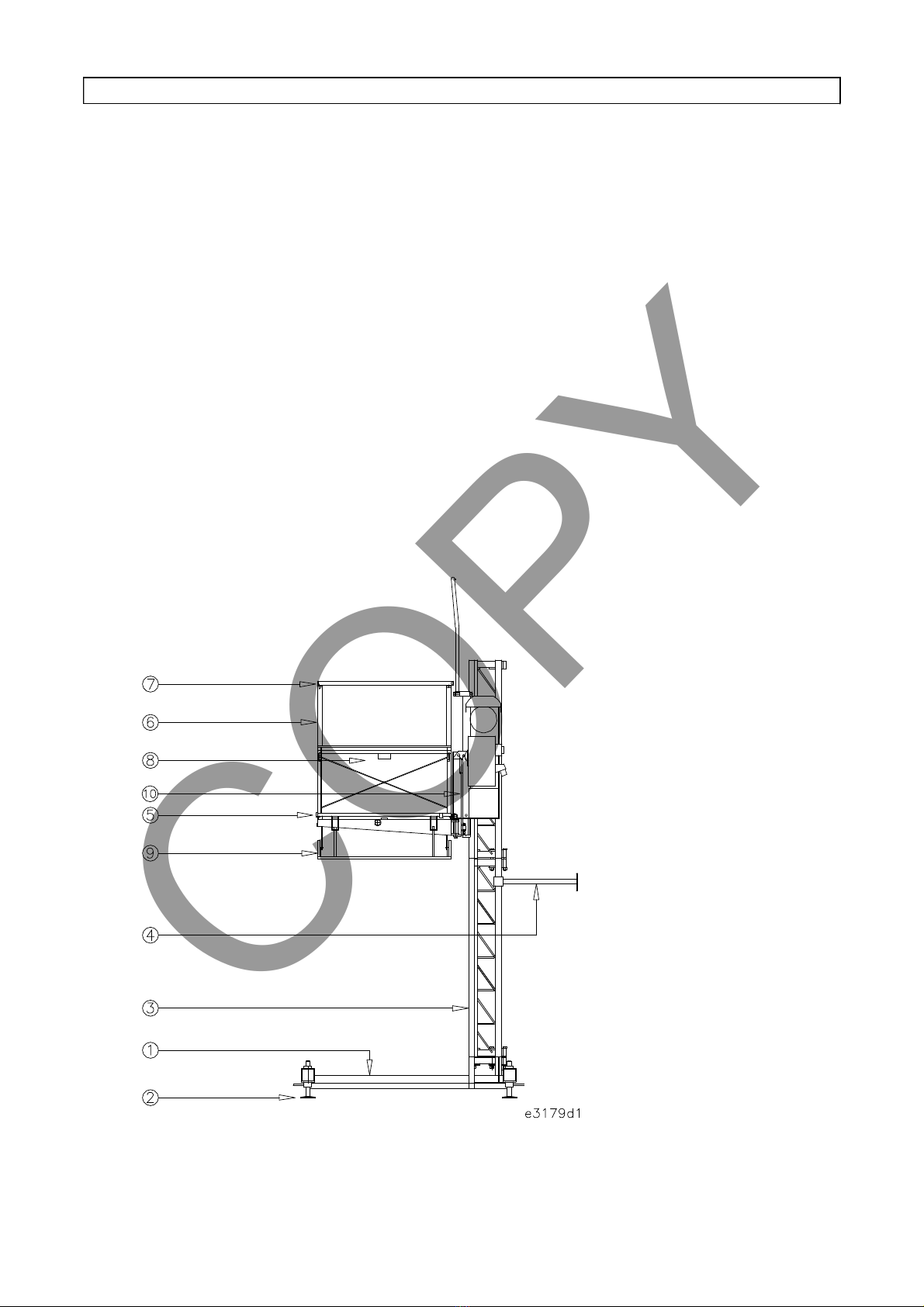

operator can immediately consult it at any time. The drawing above shows where the

manual should be placed inside the sealed box of the electric board. Owing to the

constant and continuous improvements made by manufacturer to the product, the supplied

machine might differ in some technical details from that described in this manual. However,

any variation is always accompanied by specific enclosed documents illustrating functionality

and features. Should there be any discrepancies compared to the content of the handbook,

the user may immediately ask for supplementary technical data sheets.