Table of Contents

List of Tables................................................................................................................................................3

List of Figures ..............................................................................................................................................3

Welcome.......................................................................................................................................................4

Overview.......................................................................................................................................................4

Contents........................................................................................................................................................4

Installation....................................................................................................................................................4

Safety............................................................................................................................................................5

User Alerts....................................................................................................................................................5

Installation....................................................................................................................................................5

Controls and Features ..................................................................................................................................6

Parameter Settings.......................................................................................................................................7

Pressure Regulator Setting .......................................................................................................................7

Process Timer Setting................................................................................................................................7

System Operation.........................................................................................................................................7

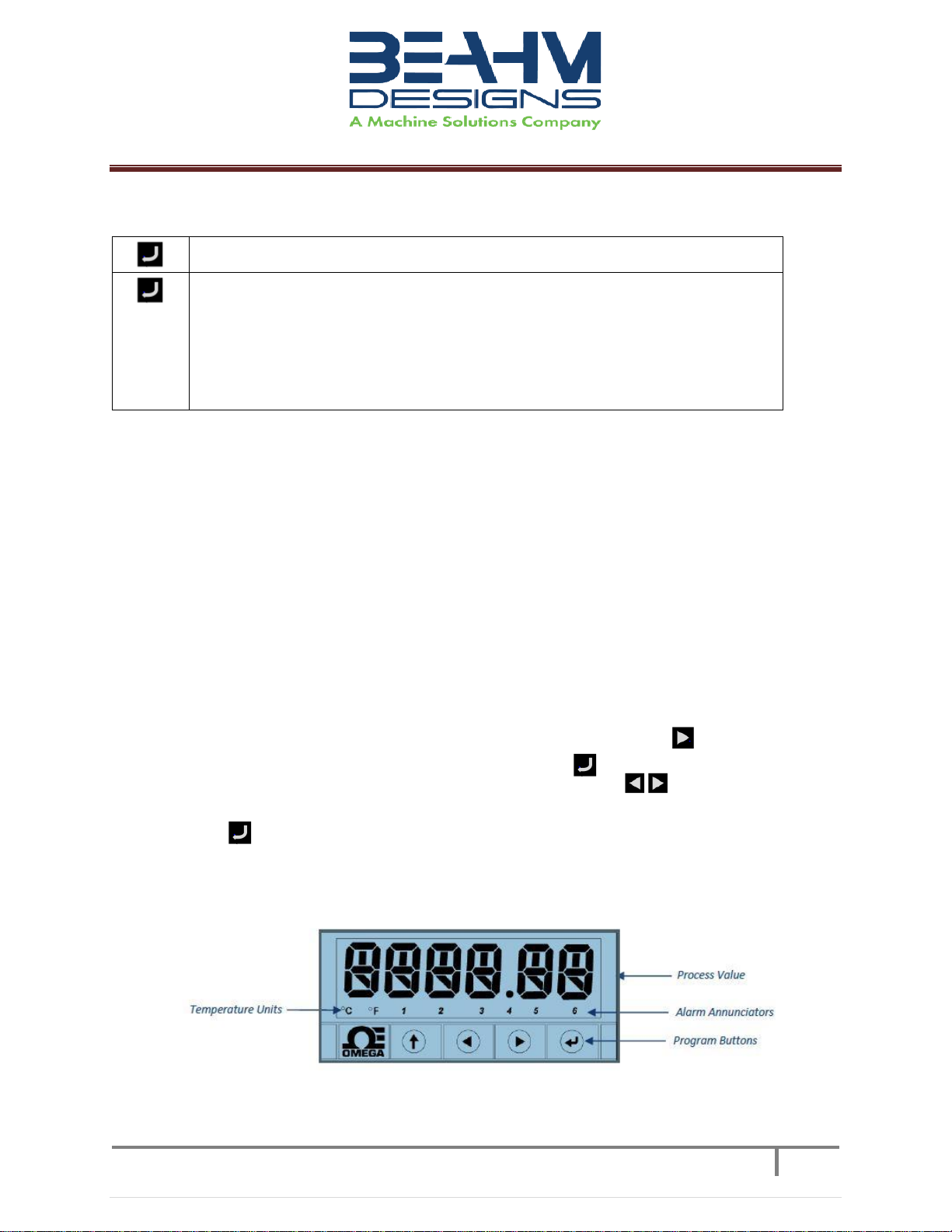

Temperature Controllers (Omega Platinum Model)..........................................................................8

PID Configuration (PRoG > PId.S).......................................................................................................8

Action Response (PRoG > PId > ACtN)...............................................................................................8

Autotune Timeout (PRoG > PId > A.to)..............................................................................................8

Autotune (PRoG > PId > TUNE)..........................................................................................................9

Adjusting Temperature on Controllers (Omega Platinum Model).....................................................9

Temperature Controller Layout and Description of Button Actions..................................................9

Resetting the temperature controller .............................................................................................10

Changing Temperature Units on the Omega Temperature Controller............................................19

Maintenance...............................................................................................................................................19

Exchanging Die Heads.............................................................................................................................20

System Specifications.................................................................................................................................20

Calibration ..................................................................................................................................................20

Critical Spare Parts .....................................................................................................................................21

Diagnostics (Troubleshooting)...................................................................................................................21

Facilities Requirements..............................................................................................................................22

Warranty.....................................................................................................................................................22