Table Of Contents

Welcome ......................................................................................................................................... 3

Purpose ........................................................................................................................................... 3

Overview......................................................................................................................................... 3

Contents.......................................................................................................................................... 3

Installation ...................................................................................................................................... 3

Safety............................................................................................................................................... 4

User Alerts....................................................................................................................................... 4

Die Head Replacement ................................................................................................................... 5

Parameter Settings ......................................................................................................................... 5

Cooling Air ON Toggle.................................................................................................................. 5

Cooling Air Flow Adjust................................................................................................................ 5

System Operations.......................................................................................................................... 5

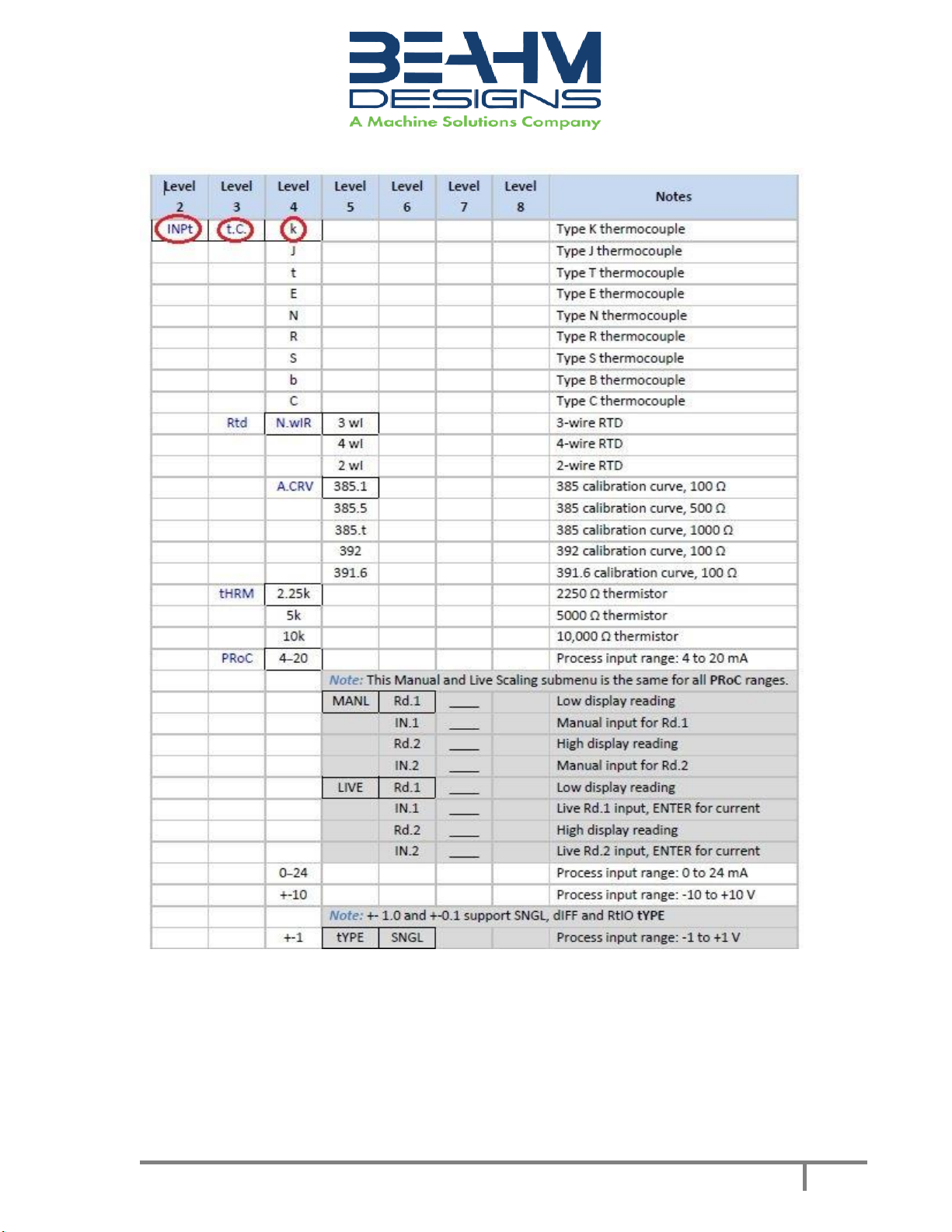

Temperature Controllers (Omega Platinum Model) .................................................................... 6

PID Configuration (PRoG > PId.S)................................................................................................. 6

Action Response (PRoG > PId > ACtN).......................................................................................... 6

Autotune Timeout (PRoG > PId > A.to) ........................................................................................ 6

Autotune (PRoG > PId > TUNE) .................................................................................................... 7

Adjusting Temperature on Controllers (Omega Platinum Model) ............................................... 7

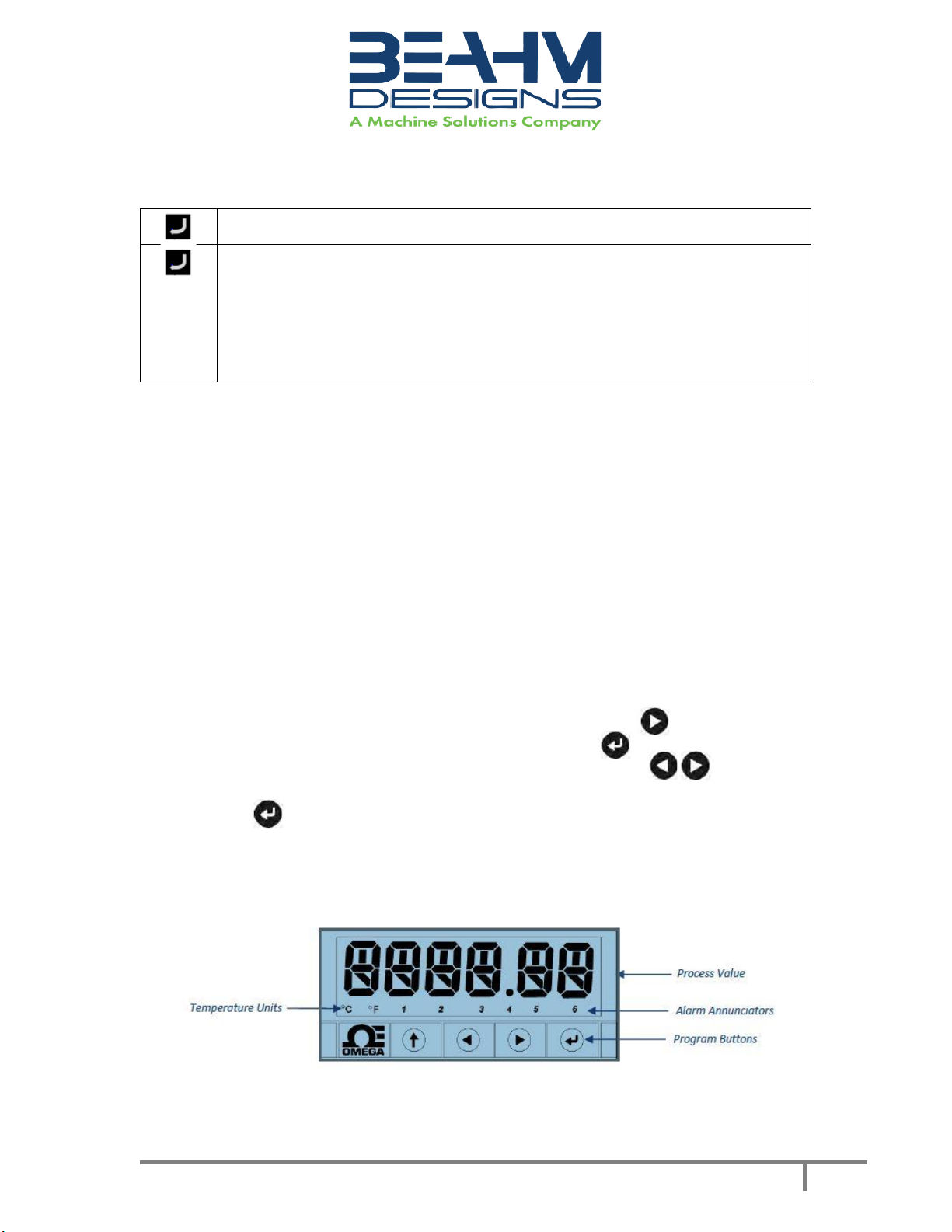

Temperature Controller Layout and Description of Button Actions ............................................ 7

Resetting the temperature controller.......................................................................................... 8

Changing Temperature Units on the Omega Temperature Controller ...................................... 17

Maintenance................................................................................................................................. 17

Facility Requirements ................................................................................................................ 18

Warranty....................................................................................................................................... 18

Return Material Authorization.................................................................................................. 18