SPEAKER

ART500ATwo-Way Active Speaker System

ART500A

6

www.mackieindustrial.com

16220 Wood-Red Rd NE, Woodinville, WA 98072 USA

888.337.7404, fax 425.487.4337, industrial@mackie.com

UK + 44 1268 570 808, fax + 44 1268 570 809, industrial@rcf-uk.com

FRANCE +33 3 8546 9160, fax +33 3 8546 9161, industrial@rcf.fr

GERMANY +49 2572 96042 0, fax +49 2572 96042 10, industrial@mackie.de

Electronic les for this product available at:

www.mackieindustrial.com

This Specication Sheet ART500A.PDF

Architects’ & Engineers’ Specications ART500AAE.TXT

Quick-Start Manual ART500AQS.PDF

Owner/Operator’s Manual ART500AML.PDF

CADD les ART500A.DXF

EASE data ART500A.EAS

6OF 6 PAGES

Architects’ & Engineers’ Specications

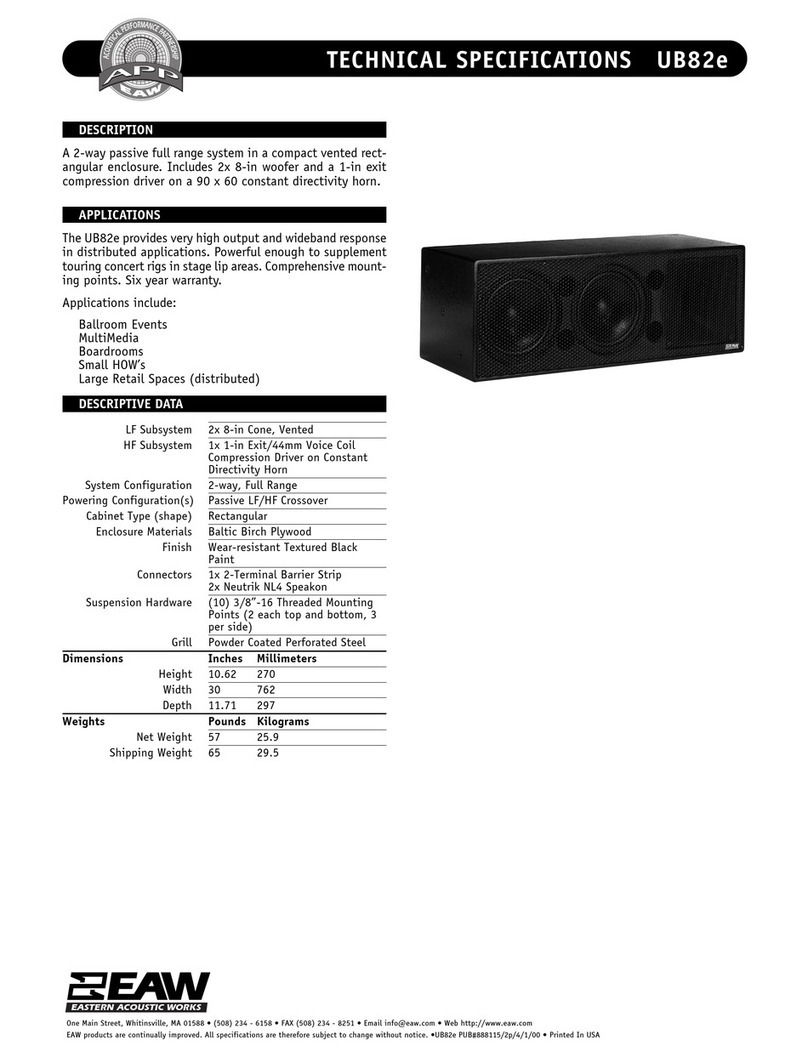

The amplied loudspeaker system shall be a self-

contained unit, housed in a reinforced polypropylene

enclosure and consisting of the following sub-sys-

tems: (1) vented two-way loudspeaker system, (2)

integrated power ampliers and crossover network,

(3) integrated mic/line input with music and voice

equalizers.

The loudspeakers shall consist of a 15 inch low-

frequency, cone driver, with at least a 3 inch voice

coil, and an 80° x 60° high-frequency, constant-

directivity polynomial horn with a horn-loaded,

2 inch compression driver having a titanium dia-

phragm and compensated for horn resonance and

ringing. The drivers shall be aligned with an analog

circuit and crossed over at 1.2kHz by a 4-pole network

built into the power ampliers. Together they shall be

capable of producing 126dB SPL (1m, anechoic).

Two discrete ampliers shall be provided,

capable of continuously delivering 400W RMS to

the low-frequency driver and 100W RMS to the high-

frequency driver. Distortion shall be less than 0.1%

when measured at 1kHz and 10kHz. They shall be

equipped with a multi-function protection circuit to

peak limit and protect the loudspeakers from over-

heating, over-excursion, overloads, short circuits

and extreme operating temperatures. An indicator

light shall illuminate when any aspect of the protec-

tion circuit engages.

The integrated mic/line input shall be actively

balanced, may also accept an unbalanced input, and

shall be paralleled to an output. Both shall have XLR

connectors. The input shall have a switch to select

between 10mV mic and 775mV line levels. The unit

shall be provided with both voice and music optimi-

zation equalization that can be activated with but-

tons on the rear panel. The voice equalizer shall pro-

vide +4dB at 3kHz and +4db at 6kHz. The music

equalizer shall provide +4dB at 65Hz and +4dB

at 12kHz. A continuously variable, rotary master

volume control shall be provided.

The power supply shall be internal and con-

nected to 50 or 60Hz source current through a

detachable IEC power cord and shall have an IEC

socket for mains power loop-through. It shall have

an on/off switch, fuse holder and threaded ground-

ing screw on the rear panel. AC voltage shall be

selectable between 115 and 230VAC. The power

supply shall draw a maximum of 5A and illuminate

an indicator light when on.

The reinforced polypropylene enclosure shall

have a volume of at least 2.64 cu. ft., be trapezoidal

shaped and equipped with a grille to protect the

cone driver. At least four M10 and two M8 threaded

sockets and stand socket shall be molded into the

cabinet for attaching mounting hardware, designed

for the unit and available from the manufacturer.

The amplied loudspeaker system shall be a model

ART500A manufactured by Mackie Industrial.

Mackie Designs continually engages in research related to product improvement. New material,

production methods, and design renements are introduced into existing products without notice

as a routine expression of that philosophy. For this reason, any current Mackie Industrial product

may differ in some respect from its published description, but will always equal or exceed the

original design specications unless otherwise stated. ©1999-2000 Mackie Designs Inc. All

rights Reserved. and are registered trademarks of Mackie Designs Inc. Mackie

Industrial is a trademark of Mackie Designs Inc.

part no. 910-166-10