3

2. Attention

a. Please read the following instructions before installation, use and maintenance.

b. Installation, must be completed only by competent persons only, and in accordance with this manual.

c. Check all water connections are sealed and tested before operating the heat pump

d. Except for the methods recommended by the manufacturer, do not use any methods to accelerate

the defrosting process or clean the frosted parts.

e. If a repair is required, please contact the nearest after-sales service center. The repair process must

be strictly in accordance with this manual. Repairs made by unauthorized persons may void the

warranty.

f. Correctly set temperature required for personal preference making sure to avoid overheating or

overcooling.

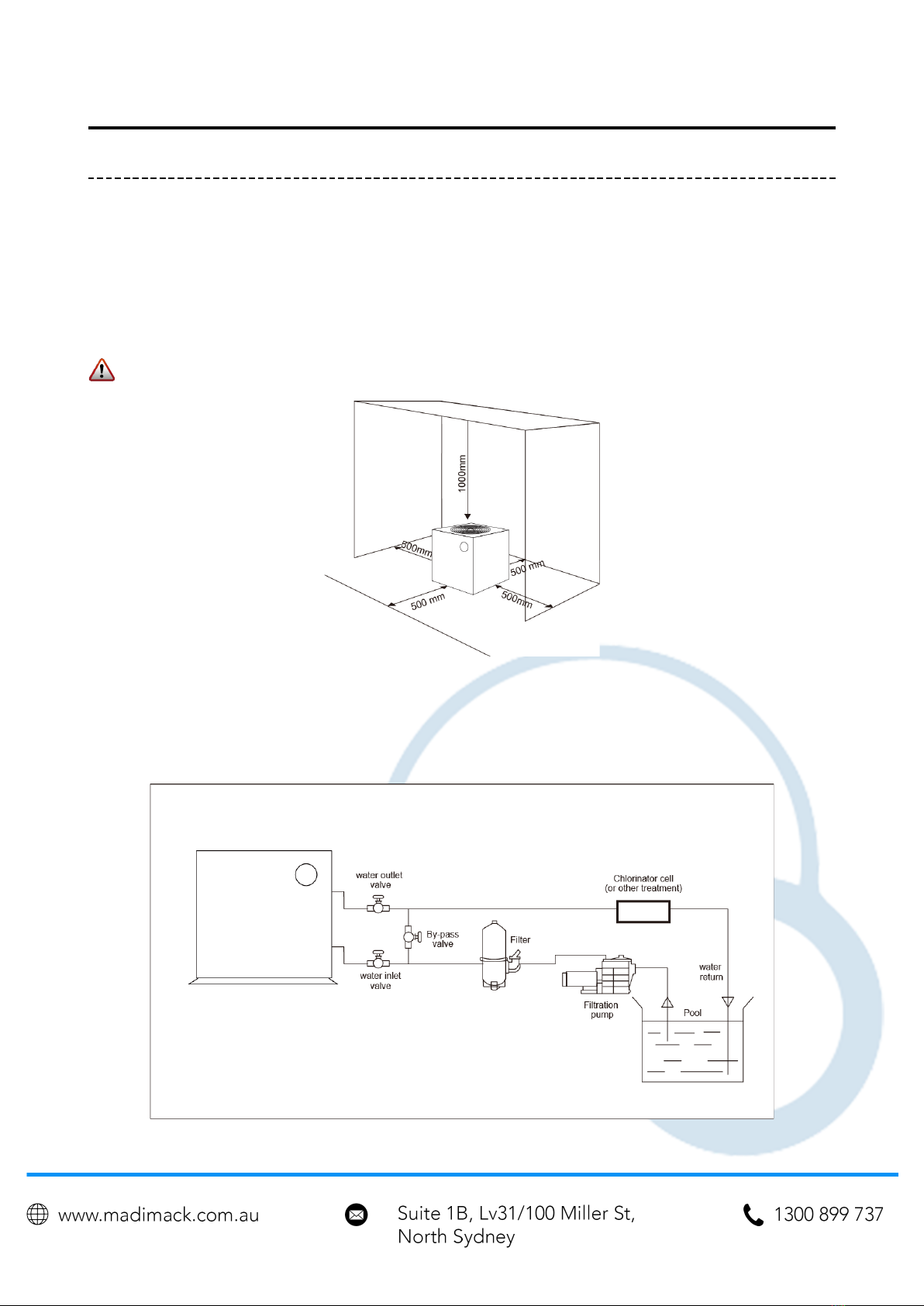

g. Please do not stack substances or other materials which may block the air flows to the inlet or outlet

areas. This causes the efficiency of the heater to be reduced, and may damage the machine.

h. Do not use or stock combustible gas or liquids such as thinners, paint and fuel, to avoid fire!

i. In order to optimize the heating effect, please install heat preservation insulation on pipes between

swimming pool and the heater, and please use a recommended cover on the swimming pool.

j. Connecting pipes of the swimming pool and the heater should be less than 10m.

3. Safety

a. Please keep the main power supply out of reach from the children.

b. If power is suddenly disconnected during operation, and later the power is restored, the heater will

start up automatically.

c. Please switch off the main power supply in high storm weather to prevent the machine from damage

that could be caused by lightning strikes.

d. Any repairs should be carried out in a well-ventilated area. Any source of ignition is prohibited during

the inspection.

e. Safety inspections must be carried before the maintenance or repair for heat pumps with R32 gas in

order to minimize the risk.

f. If R32 gas leaks during the installation process, all operations must be stopped immediately and call

your local service center.