www.madur.com Manual maMoS100/200/300/400

Contents

1. Introduction....................................................................................................................4

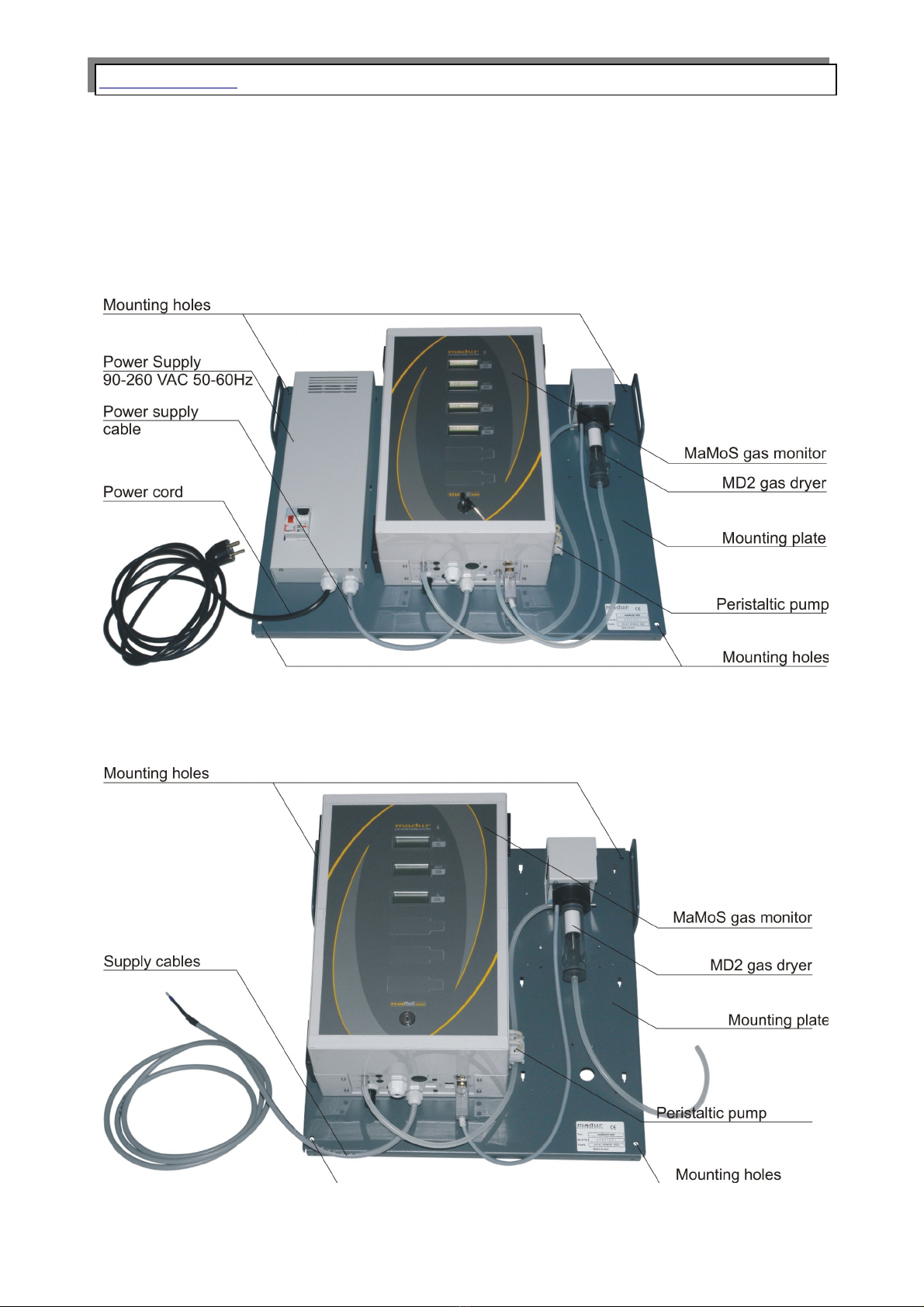

2. Package content............................................................................................................5

3. Monitor construction.....................................................................................................6

3.1. Casing.....................................................................................................................7

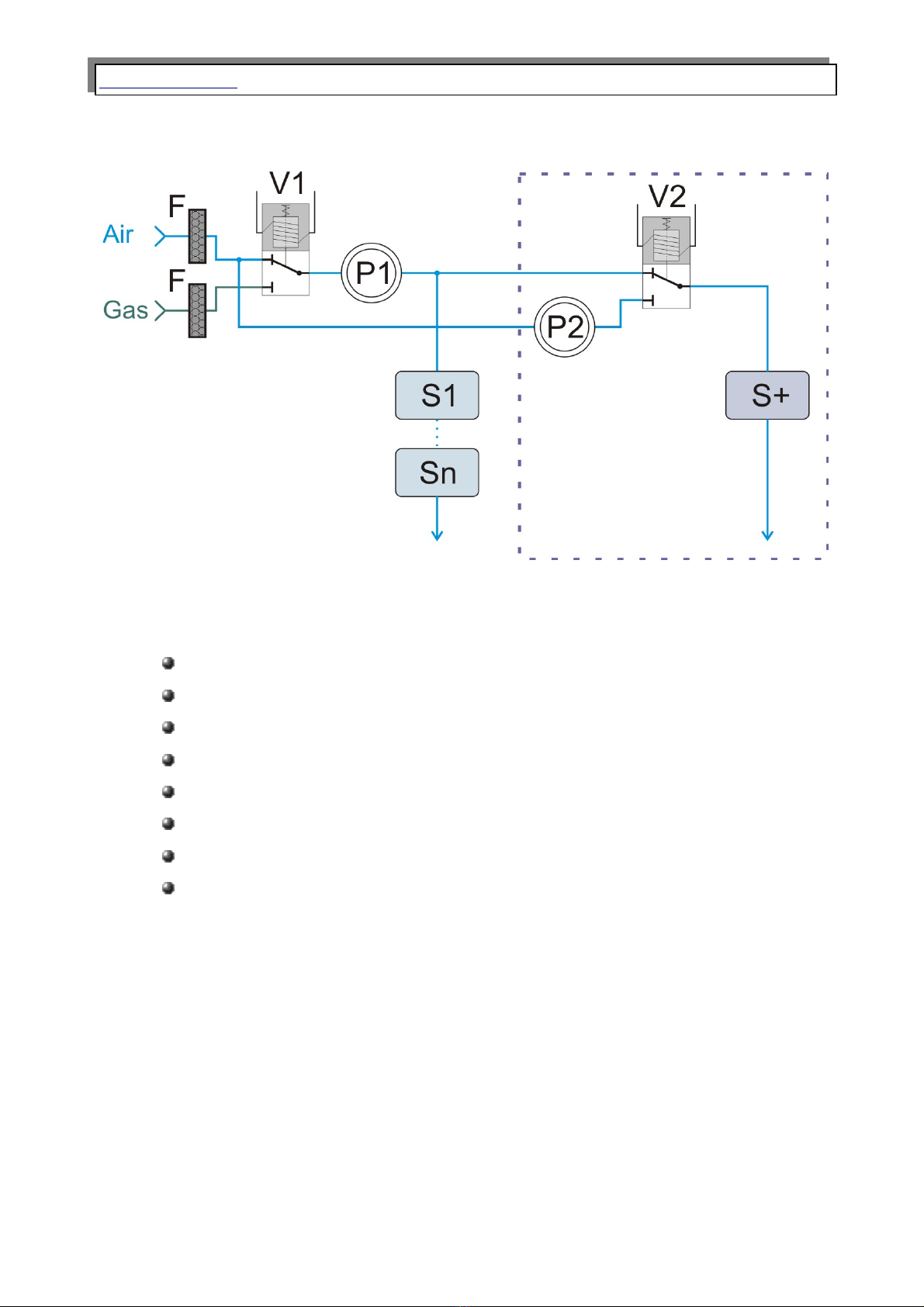

3.2. Gas channel............................................................................................................9

3.2.1. Gas dryer with filter......................................................................................10

3.2.2. Peristaltic um ............................................................................................11

3.2.3. Solenoid valve...............................................................................................12

3.2.4. Gas um ......................................................................................................12

3.2.5. Gas sensors..................................................................................................12

3.3. Electric connectors of the monitor....................................................................13

3.3.1. Digital in uts.................................................................................................13

3.3.2. Analogue out uts.........................................................................................14

3.3.3. Digital out ut (PWM)....................................................................................15

3.3.4. Relay out uts (o tional)...............................................................................16

3.4. Monitor ower su ly..........................................................................................17

3.5. Configuration ossibilities..................................................................................18

3.5.1. Ty es of the measured gases.....................................................................18

3.5.2. Additional and o tional equi ment............................................................19

4. Monitor installation.....................................................................................................20

4.1. Connecting the monitor.......................................................................................21

4.1.1. Connecting the electric wires......................................................................21

4.1.2. Connecting the gas hoses...........................................................................24

4.2. First start-u .........................................................................................................27

5. O eration......................................................................................................................27

5.1. Basic o eration....................................................................................................27

5.2. Monitor function...................................................................................................28

5.2.1. Cyclic work mode.........................................................................................28

5.2.2. Scheduled work mode..................................................................................30

5.3. Communication with monitor.............................................................................31

5.3.1. Monitor network (RS485).............................................................................32

5.3.2. Communication via USB ort......................................................................33

5.3.3. Communication via Ethernet.......................................................................37

5.4. MMC module. .......................................................................................................41

5.4.1. Possible flashing sequences of the MMC control diode lam ................44

5.4.2. Formatting SD / MMC card in FAT-16 file system.....................................44

5.5. U dating the monitor's firmware........................................................................45

5.5.1. The rocedure of u dating firmware..........................................................45

5.6. Flow velocity measurement................................................................................49

5.7. Re lacing the dryer filter.....................................................................................51

5.7.1. Re lacing the filter in MD2 dryer................................................................51

5.7.2. Re lacing the filter in MD3 dryer................................................................53

5.8. Re lacing the head of the eristaltic um ......................................................54

6. Presenting the results.................................................................................................54

6.1. Calculating the results.........................................................................................55

2