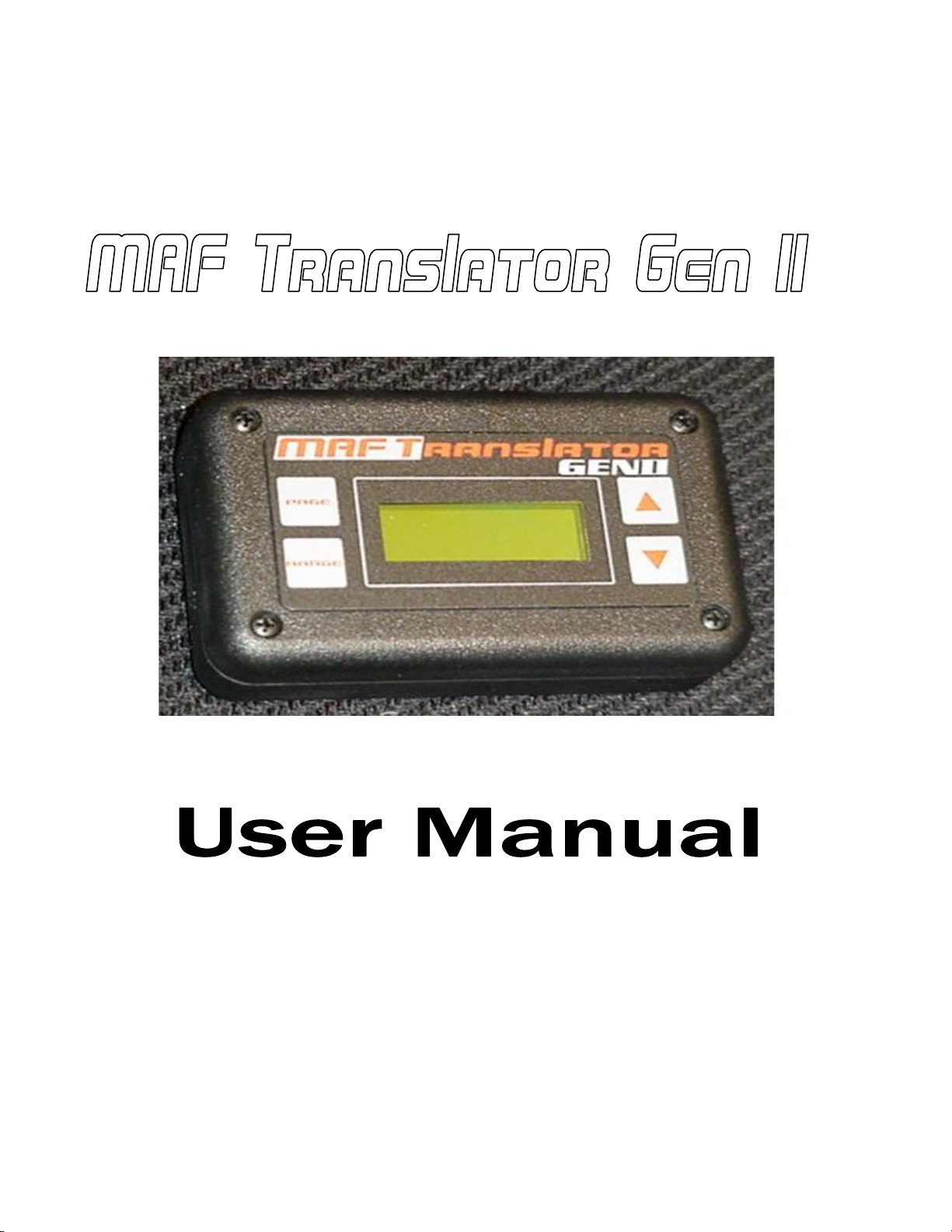

MAF Translator Gen

-

II

Use

r Manual

- - 4 - -

The primary function of the

MAF Translator Gen

-

II

is to allow the user to

adjust the air

-

fuel ratio of their engine. This is accomplished by adjusting

the amount of airflow the Engine Computer Module (ECM) or Engine

Control Unit (ECU) perceives

is entering the engine. If the ECM/ECU

senses less airflow is entering the engine, it will command less fuel be

injected into the engine, thus making the Air/Fuel ratio "leaner". If the

airflow signal is reduced by 1%, the resultant fuel delivery will b

e less by

1%.

For example, an engine is consuming 100 grams of air per second, and

the ECU is delivering fuel for 12:1 Air/Fuel Ratio (AFR). If the airflow

signal to the ECU is reduced to 95 grams per second (

-

5%)

, the

ECU will

delivery fuel for this amo

unt of air. The resulting AFR will be 12.6:1 (5%

leaner).

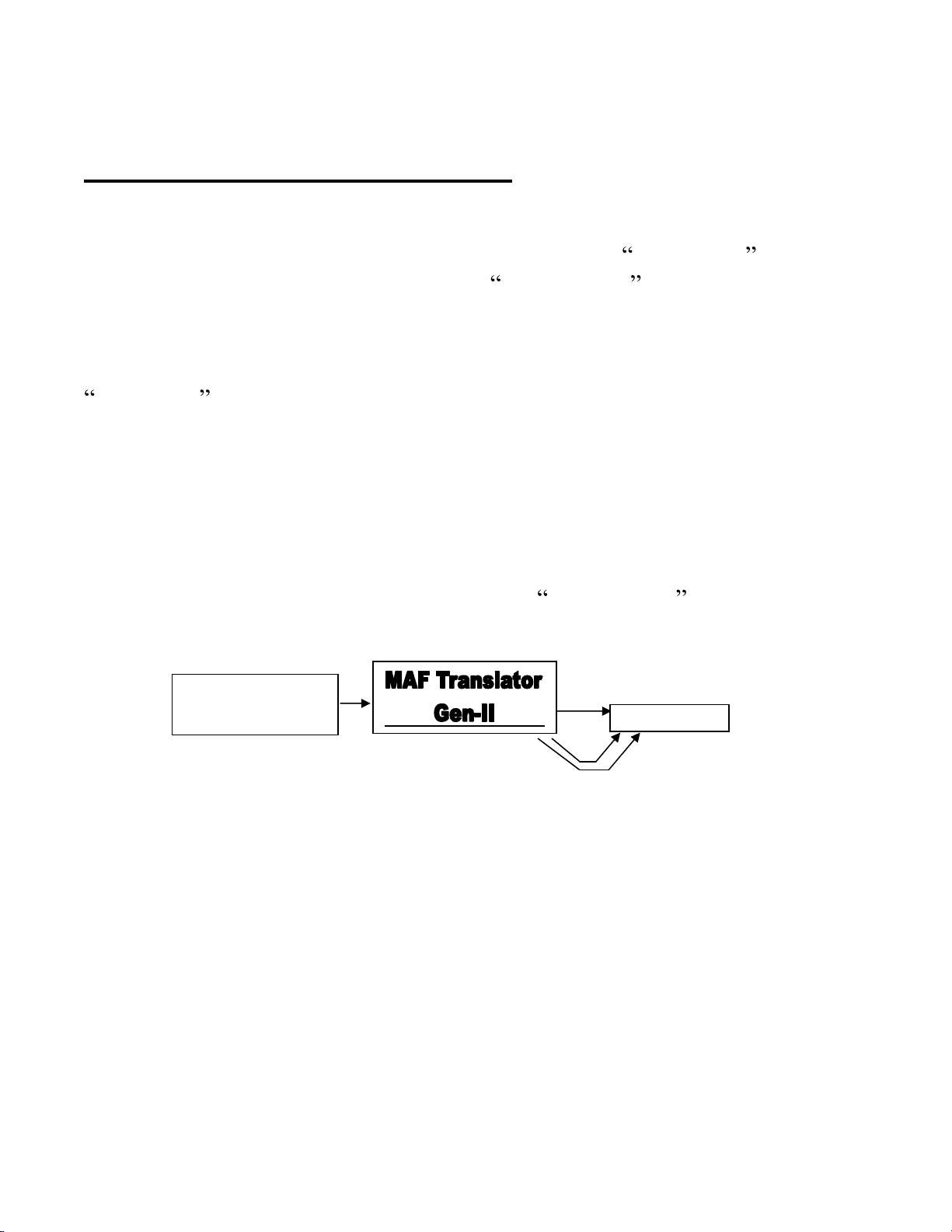

Main Airflow Modes

The

MAF Translator Gen

-

II

sends airflow information in the form of an

electrical signal (voltage or pulse frequency) to the ECU. Frequency signals

are send out

on the green,

"frequency out" wire of the 10 pin harness.

Voltage signals are sent

out

on the Brown (V Out 1) or the Gray (V out 2)

wires of the 10 pin

Main

harness.

The unit can be used to tune the vehicl

e

using the original MAF sensor,

or an upgraded, alternative sensor can be

used

.

Examples include using a GM LS1 or LS6 MAF on a Toyota Supra

,

Mitsubishi

Eclipse, or Ford SVO Mustang.

The MAF Translator Gen

-

II is

compatible with a great number of MAF sensors, both frequency

style

and

voltage.

Installation Details

This section contains installation details that are not specific to any particular

vehicle. Please refer to the appendix and other installation diagrams

contained in the

MAF Translator Gen

-

II

kit.

Harness connections are

referre

d to by connector desig

nation M or

A

(Main

or Aux

) and

pin number

,

for

example the +12V main power input is connected to the pink wire at M5

,

Ground at M10

.

In this manual, TAP means to connect to a harness wire

without cutting it. Splice means to cut a harness wire and co

nnect

MAF

Translator Gen

-

II

wires to the cut ends.

If a connection diagram specific to