6

CHAPTER 1 - GENERAL INFORMATION

1-1 OPERATING REMARKS

WOOD PROCESSING MACHINES CAN BE

DANGEROUS.

1) Careful and accurate compliance with the

directions provided by this instruction book

will allow the user to use the machine in a

safe and proper way.

2) The machine must only be used by skilled

andadultstaff. The Safetymanagershould

make sure that the person in charge of

using the machine has read and under-

stood the directions provided by this in-

struction book.

3) The staff in charge of the scheduled and

unscheduled maintenance of the machine

must have a good mechanic and electronic

background.

4) Stay away from any moving part of the

machine.

Never touch the blade while the machine is

running.

5) Never place the pieces to be processed on

top of each other. Always saw one piece at

atimeafterproperlyadjustingthemachine.

THE HANDLING OR REMOVAL OF THE

SAFETY DEVICES CAN CAUSE SERIOUS

ACCIDENTS. DO NOT REMOVE, SWITCH

OFF OR ALTER SUCH SAFETY DEVICES.

IN ADDITION, MAKE SURE THAT THE

SAFETY DEVICES ARE IN WORKING OR-

DERAT ALL TIMES, BYINSPECTING THEM

AT REGULAR INTERVALS.

IMMEDIATELY CORRECT ANY FAULT OF

FAILURE.

1-2 DESCRIPTIONOFTHEMACHINE

Radial squaring machines are used for cutting

wood or wood-like boards so as to obtain

squaredor45°-cutpieces.Thecuttingcapabili-

ties of the machines can be drawn from the

table contained in paragraph 1-5.

Working is carried out as follows:

- lay the piece down and keep it pressed

against the square abutting end;

- setthemachineforthedesiredcuttingdepth,

and the required direction and blade-to-

piece angle;

- move the blade away for a further check,

thenstartthemotorwhilekeepingahandon

the grip; use the other hand to exert suffi-

cient pressure on the piece to be worked;

keep your hand at a safe distance from the

cutting line;

- pull the carriage, exercising extreme cau-

tionwhenthebladecomesintocontactwith

the piece, so as to avoid possible cutting

reactions;

- After the cutting, stop the machine moving

the blade to its home position and remove

the cut pieces.

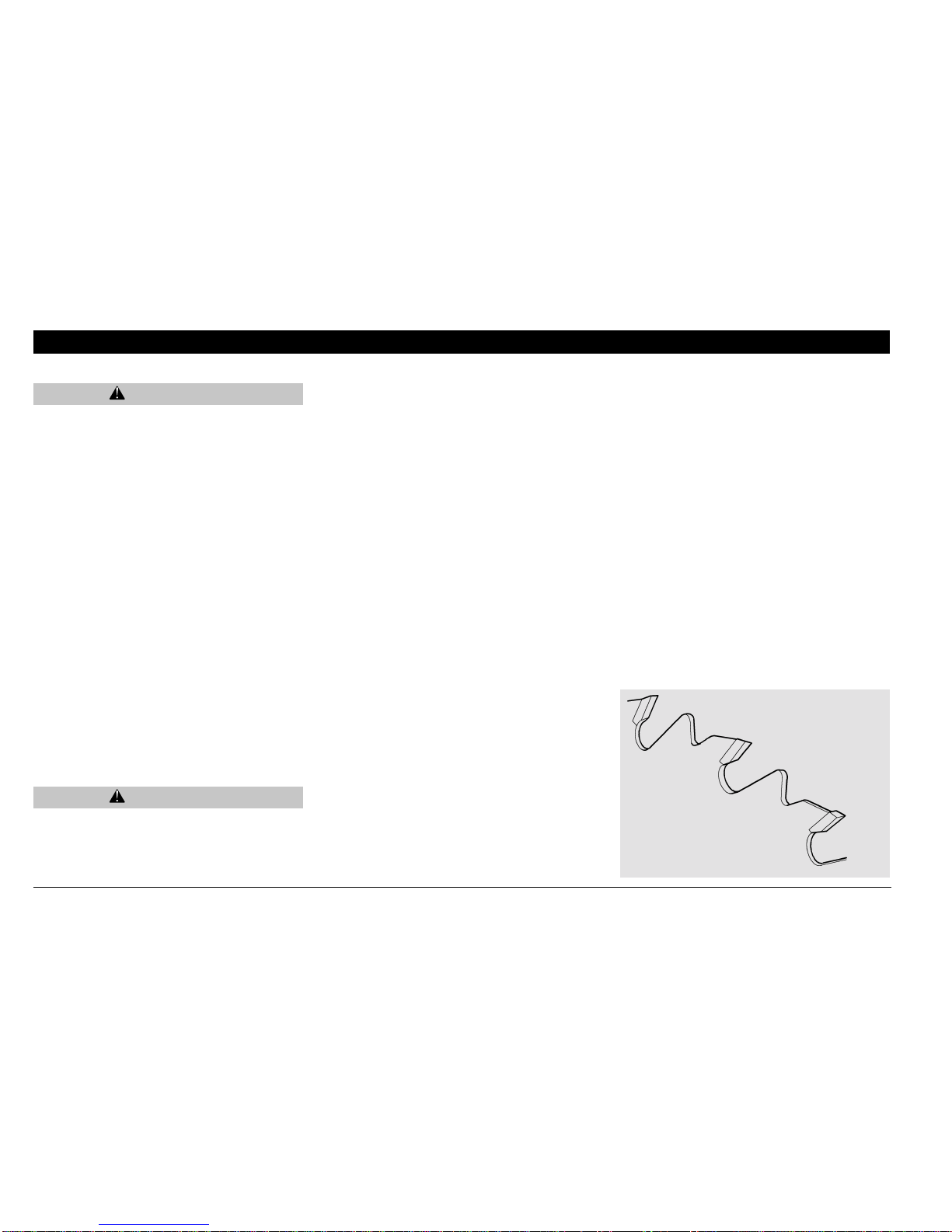

1-2.1 USABLE TOOLS

As regards the USABLE tools, Maggi Engi-

neeringrecommendtheuseofbladesfitforthe

type of process to be carried out, and THAT

such blades should be highly reliable, should

not recoil and should pose a low risk of acci-

dents.

Maggi Engineering’s technicians, according to

their studies and tests, recommend the use of

universal disk blades for longitudinal cuts and

cross-cuts with alternating teeth (fit for radial

saws).

In any case, the blade diameter to be used is

Dia.350/400mm.

Fig.Ashowsauniversaldisk saw for longitudi-

nal cuts and cross-cuts with alternating teeth.

Fig.A

WARNING

WARNING

Disk saw

withalternatingteeth